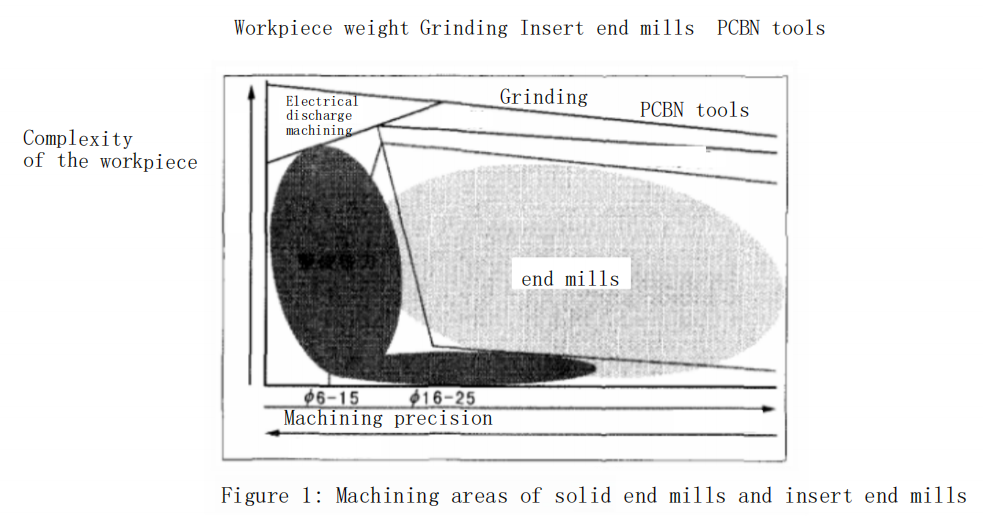

Generally, compared to traditional insert end mills, solid carbide end mills offer significantly higher machining precision. This fact holds true specifically for the performance of the tool during cutting operations. Although both types of tools may have the same dimensional precision grade, the rigidity of solid carbide material is much higher than that of a steel tool holder with insert blades. This means that solid carbide end bit mills are less likely to undergo deflection or deformation under cutting forces, leading to higher machining precision.

Base Material of Solid Carbide End Mills

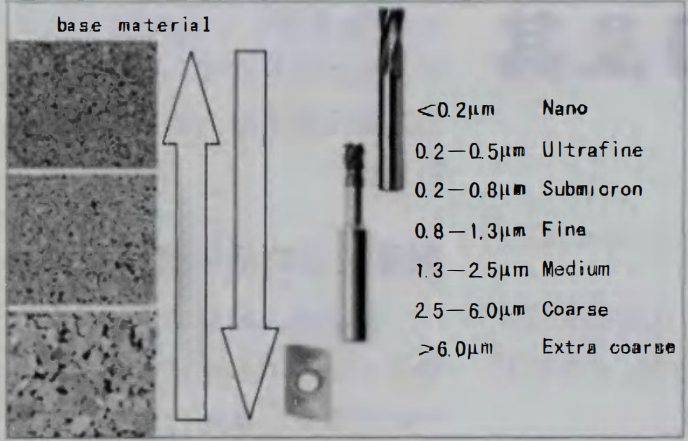

The machining performance of solid carbide end mills largely depends on the type of carbide base material used. The base material is crucial because it must support the cutting edges of the tool, endure significant cutting forces, and prevent any form of tool damage.

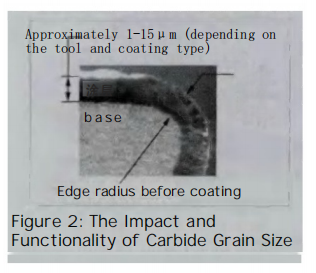

To ensure that end mills have sufficient toughness and provide good dynamic resistance, solid carbide end mills typically use micro-grain carbide as the base material (see Figure 2). This base material offers higher hardness and better edge sharpness while maintaining good toughness. However, compared to conventional grain-sized carbide, micro-grain carbide has relatively poorer thermal conductivity (its ability to dissipate heat from the cutting area). This means that heat generated during cutting tends to remain on the tool surface. Therefore, the cutting edges of solid carbide end mills must be able to withstand this cutting heat and manage the contact arc length, which is an important consideration when selecting solid carbide end mills.

Coating and Cutting Edge Preparation of Solid Carbide End Mills

To enhance tool wear resistance and isolate the cutting zone, which generates heat, from the tool base (since heat accumulation in the base material can shorten tool life), solid carbide end mills are typically coated. Additionally, because the cutting edges of solid carbide end bit mills are quite sharp, appropriate adhesion between the tool base and the coating is also crucial (see Figure 3). This is especially important for smaller diameter solid carbide end mills, where the sharpness of the cutting edges is a key factor in the tool’s machining performance.

The Ideal Cutting Edge for Solid Carbide End Mills

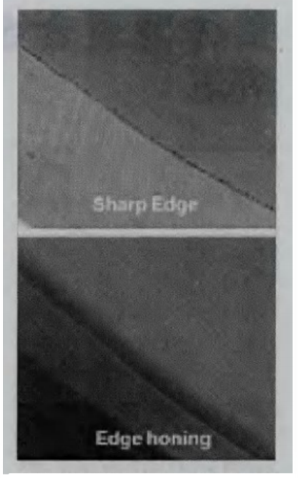

The ideal cutting edge of a solid carbide end mill should have as high a hardness as possible while minimizing the risk of chipping. This goal can be partially achieved through proper cutting edge preparation. Generally, different solid carbide end mills may employ various cutting edge preparation methods, edge geometries, and sharpness levels depending on the required machining quality and tool life.

The cutting edge is the intersection line between the tool’s rake face and flank face. By grinding these faces, a sharp cutting edge can be obtained. However, if a PVD coating is deposited directly on a sharp cutting edge, it can create high internal stresses within the coating. These high internal stresses can cause the coating to crack and peel off during cutting, thereby shortening the tool’s life. The quality and effectiveness of the coating depend on its ability to withstand and/or reduce the wear rate during cutting. To ensure that the coating adheres more firmly to the cutting edge and to prevent edge damage, it is necessary to perform edge reinforcement (or blunting) treatment (see Figure 4). In other words, to ensure machining stability and achieve coating functionality, a certain degree of edge sharpness must be sacrificed, which in turn extends tool life.

It can even be said that the importance of cutting edge preparation for solid carbide end bit mills outweighs that of base material type and coating technology. Logically, this has a significant impact on the regrinding of solid carbide end mills. After regrinding, if the cutting edge is not re-blunted to restore its initial condition, the full potential of the tool repair cannot be realized. Therefore, considering the high initial cost of solid carbide end mills, it is crucial for the original tool manufacturer or its qualified service centers to handle tool regrinding services.

Machining Strategies for Solid Carbide End Mills

Solid carbide end mills can be categorized into several major types based on their size and geometry, and further subdivided into many specialized subcategories according to different machining ranges. In various tool application areas, design features such as flute geometry, cutting edge angles, rake and relief angles, and helix angles play crucial roles in differentiating among the types of solid carbide end bit mills. This classification guides the selection of both end mills and machining strategies.

So, which machining strategy is the best choice? This depends on the overall machining goals: is your primary aim to maximize productivity and part output, or to minimize tool costs and simplify tool types? Additionally, it also depends on the workpiece and various related factors: is the tool used for slotting, side milling, or a combination of both?

A final consideration is constraints, such as: what is the potential machining capability of the machine tool? How rigid is the workpiece clamping? These factors might become limiting constraints, preventing the use of more advanced machining strategies or more efficient specialized solid carbide end mills.

The correct choice of solid carbide end bit mill depends on multiple factors, with the most important being the adoption of the correct machining strategy. In practice, many constraints cannot be changed: the machining machine, CAM system, and the material, size, tolerance, and shape of the workpiece are fixed constants. However, within the existing machining system framework, machining results can still be influenced by formulating the right machining strategy and using various methods, and by optimizing cutting conditions through adjustments to feed rate, cutting speed, and cutting depth according to the overall machining goals.

Based on the selected focus and technical strategy, appropriate solid carbide end mills can be chosen. There are two obvious ways to select tools:

- Performance-Based Selection:Choose specialized end mills with specific applications (such as side milling, slotting, or 3D profiling) to achieve optimal performance.

- Versatility-Based Selection:Choose general-purpose end bit mills with a wider range of applications but fewer types.

Regardless of the selection method, users need to further narrow down the options within the available varieties and specifications of solid carbide end mills.

??????

The material, size, tolerance, and shape of the machined parts are given constants. However, within the existing machining system framework, machining results can still be influenced by formulating the correct machining strategy and employing various methods. Additionally, cutting conditions can be optimized by adjusting feed rate, cutting speed, and cutting depth according to the overall machining goals.

Based on the chosen focus and technical strategy, appropriate solid carbide end mills can be selected. There are two clear approaches to tool selection:

- Performance-Based Selection:Choose specialized end mills designed for specific applications (such as side milling, slotting, or 3D profiling) to achieve the best performance.

- Versatility-Based Selection:Choose general-purpose end mills that, while fewer in types, offer a wider range of applications.

Regardless of the selection method, users need to further narrow down the choices within the available varieties and specifications of solid carbide end mills.