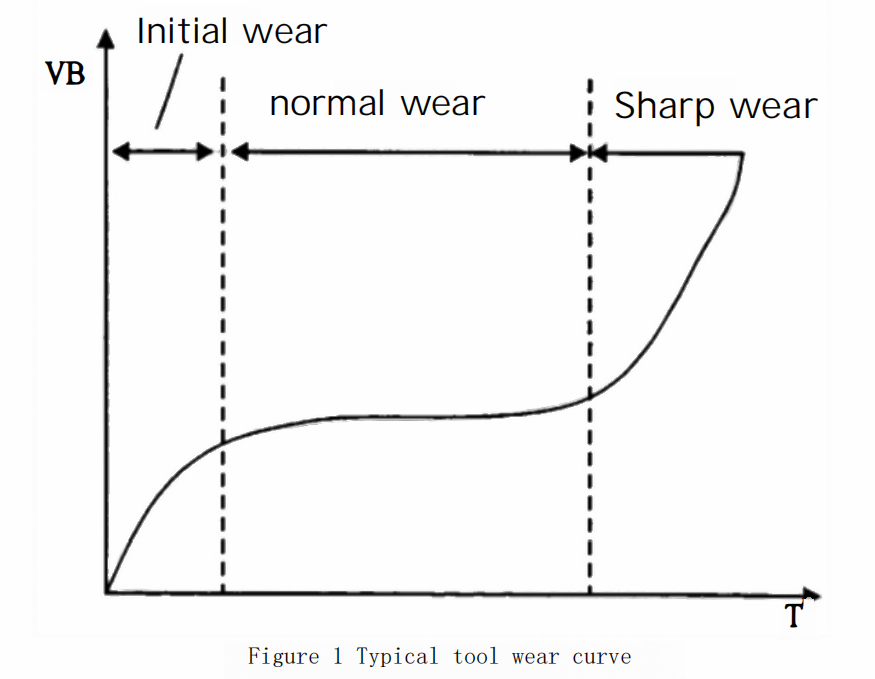

The wear on the back face of the cutting tool has a more significant impact on machining accuracy and cutting force than the wear on the front face, and it is easier to control and measure. Therefore, the back face wear land width VB is usually used as the standard for tool bluntness. The wear process generally consists of three stages: the initial wear stage, the normal wear stage, and the severe wear stage. As shown in Figure 1, during the initial wear stage, due to the rough surface of the tool, the contact area between the cutting tool surface and the workpiece is small, resulting in higher compressive stress and faster wear, with a larger slope in the schematic curve. In the normal wear stage, after the initial wear, the tool surface has been smoothed, the contact area between the tool and the workpiece increases, and the pressure decreases, so the amount of wear increases slowly and relatively stably with the extension of cutting time. When the tool wears to a certain extent, the cutting force and cutting temperature increase rapidly, the wear accelerates drastically, and the cutting tool fails.

Tool Wear Mechanism

Tool wear is often the combined result of mechanical, thermal, and chemical actions. Generally, the following mechanisms are recognized for tool wear:

Abrasive Wear

This type of wear occurs due to the presence of hard particles between contact surfaces. The mechanism of abrasive wear mainly involves the continuous micro-cutting and scoring actions of the abrasive particles on the friction surface, resulting in the formation of grooves parallel to the direction of relative motion on the friction surface. The rate of abrasive wear is directly proportional to the normal load Fn and the wear coefficient K, and inversely proportional to the material hardness H. Generally, the higher the hardness of the cutting tool material, the better its resistance to abrasive wear.

Therefore, according to the theory of friction and wear, increasing the hardness and wear resistance of the cutting tool material, achieving an appropriate hardness/toughness ratio, and reducing the surface roughness of the cutting part of the cutting tool can all decrease the abrasive wear of the tool.

Adhesive Wear

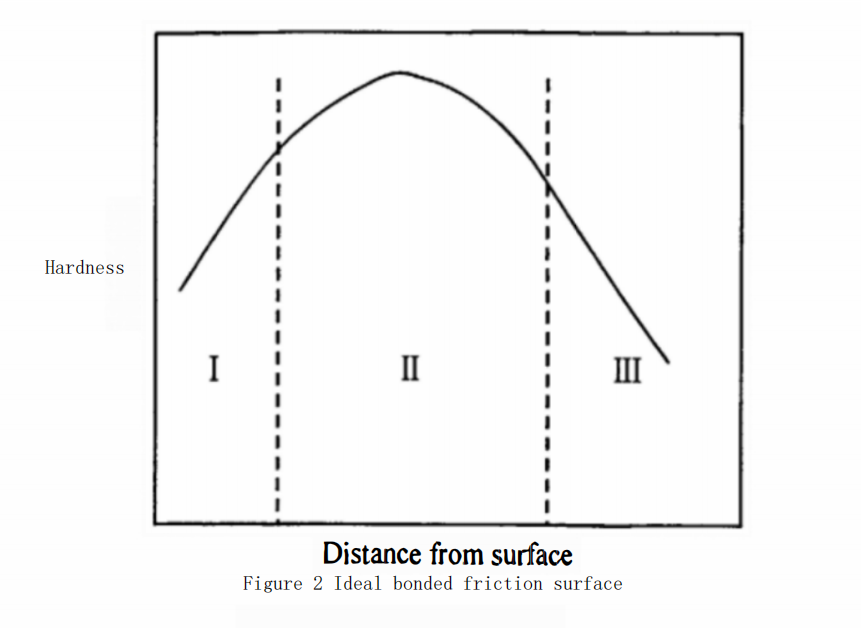

This type of wear is caused by the attraction between molecules and atoms on the contact surfaces. Under sufficient pressure and temperature, plastic deformation occurs, leading to a phenomenon known as cold welding, which is the result of the adhesive forces between the fresh surface atoms formed by the plastic deformation of the friction surfaces. An ideal adhesive friction surface is not necessarily the harder the better; it should have a surface characteristic that combines soft and hard features, as shown in Figure 2, with a soft surface (I), a hard subsurface (II), and a gentle transition zone (III) below. In other words, from the perspective of adhesive wear, the tool surface should have good lubricity, the subsurface layer should have high hardness to provide support, and the gentle transition zone below prevents the occurrence of layer-by-layer spalling of the cutting tool material.

Therefore, according to the theory of friction and wear, appropriately improving the hardness/toughness ratio can reduce the cutting force and cutting temperature, which is beneficial for reducing adhesive wear of the tool.

Diffusion Wear

Diffusion wear generally occurs during high-temperature machining processes. When cutting metal, the chemical elements of both the chip, workpiece, and tool diffuse into each other in the solid state during contact, altering the original material composition and structure, which makes the tool material become brittle and accelerates cutting tool wear. This type of wear caused by the migration of elements in the solid state is called diffusion wear. It is a type of wear characterized by chemical properties.

Oxidation Wear on Cutting tool

During the cutting process, due to the increase in cutting speed or the poor thermal conductivity of the work material, the temperature between the tool and the chip reaches high levels (700~1000℃). The tool material or the chip reacts with oxygen to form corresponding oxide films. This is also a type of wear characterized by chemical properties. Generally, during cutting, the cutting tool is in close contact with the chip and workpiece, where oxygen content is low, while in areas away from the contact zone, oxygen content is higher, leading to severe oxidation wear. During high-speed cutting, where cutting temperatures are high, oxidation wear is more likely to occur. The degree of oxidation wear is determined by the cutting speed, the amount of oxygen, and the oxidation resistance of the tool material. Therefore, selecting cutting tool materials with better high-temperature stability and a smaller wear coefficient, or using physical methods to reduce cutting temperatures, such as coolant, can reduce the occurrence of oxidation wear.

Study on the Cutting Performance and Wear Mechanism of Coated Cemented Carbide Cutting Tools

Hard coatings have advantages such as high hardness, wear resistance, low friction coefficient, high resistance to high-temperature oxidation, and good chemical stability. They are widely used in tool machining. By applying surface coating technology to deposit a layer of high-performance coating on the tool substrate, the machining efficiency and cutting tool life can be improved. Under different machining conditions, coated tools exhibit different machining performances. In some cases, the cutting performance of coated cemented carbide tools may even be lower than that of uncoated cemented carbide tools. Therefore, by studying the cutting performance and wear mechanism of coated cemented carbide cutting tools, the modification mechanism of coated cemented carbide tools can be clarified, allowing for a reasonable selection of coating materials and structures, optimization of machining parameters and tool geometric parameters, and truly achieving the goals of high-quality, efficient, and low-cost machining.

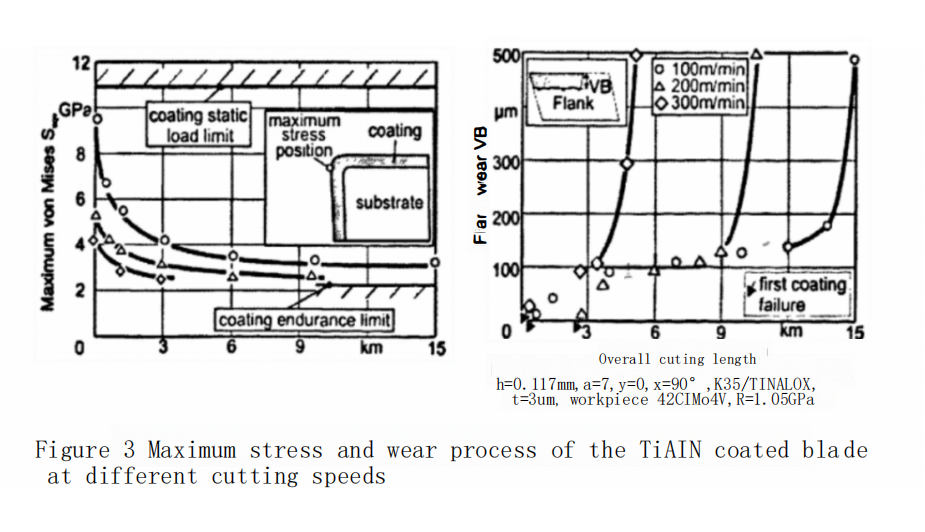

Some scholars have studied the turning of 42CrMo4V steel with TiAlN coated cemented carbide inserts at different cutting speeds. The cutting speed significantly affects the failure mode of the tool. As the speed increases, the cutting force increases, and the stress on the coating increases, leading to earlier failure of the coating. Figure 3 shows the time at which failure occurs in the TiAlN coated cemented carbide insert at different cutting speeds. The coating failure process occurs because the stress on the coating exceeds the cohesive strength of the coating or the bonding force between the coating and the substrate, resulting in the formation of fragments. Subsequently, abrasive wear dominates the cutting tool failure process.

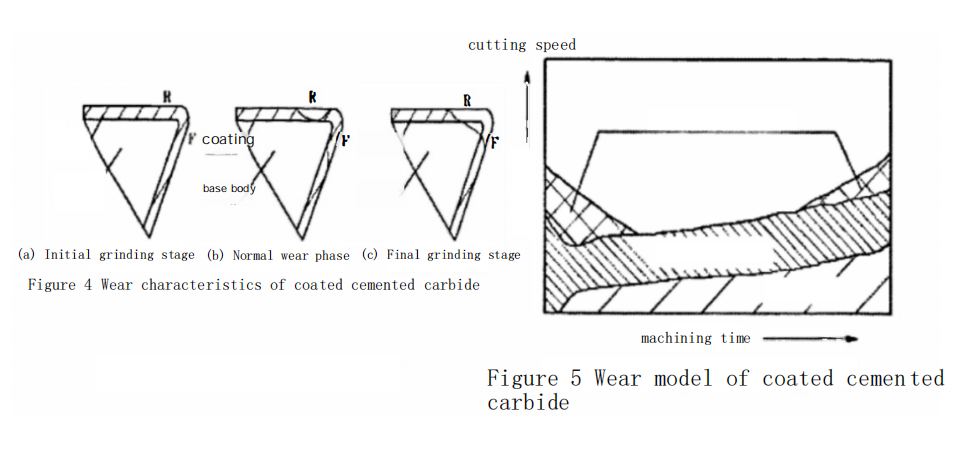

We have studied the wear mechanism of TiC coated cemented carbide cutting tools under different cutting speeds. The wear process of the coated inserts can be divided into three stages: the initial wear stage, the normal wear stage, and the final wear stage, as shown in Figure 5. As the cutting speed increases and the cutting time extends, the main wear mechanisms are diffusion wear, plastic deformation wear, and plastic fatigue spalling wear. In the initial stage of wear, severe friction occurs between the tool and the chips on the front and back surfaces of the cutting tool, respectively, resulting in plastic slip of the surface coating material in the opposite direction of cutting tool feed. This leads to plastic fracture of the coating material on the front and back surfaces, which is plastic fatigue spalling wear, and the coatings on the front and back surfaces are worn through at points R and F as shown in Figure 4. In the normal wear stage, although the coatings at points R and F are worn through, the surrounding coatings play a supporting role, thus delaying the expansion of the worn-through areas on the front and back surfaces of the tool.