The classification of carbide?grades is mainly divided into three categories: cutting tool carbide?grades, geological and ore tool carbide?grades, and wear-resistant parts carbide?grades.

Carbide?Grades for Cutting Tools

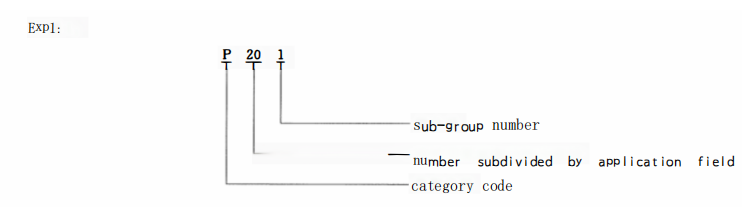

The carbide?grades for cutting tools are mainly classified into six categories based on their application areas: P, M, K, N, S, and H. The identification of carbide?grades for cutting tools involves testing various indicators such as element composition, Rockwell hardness, Vickers hardness, flexural strength, metallographic structure (porosity, non-combined carbon, macroscopic pores), etc. The alloy performance recommended for operating conditions is primarily assessed based on indicators like wear resistance, toughness, cutting speed, feed rate, etc. The representation rules for carbide?grades for cutting tools are mainly composed of category codes, group numbers, and sub-group numbers, as shown in the diagram below.

concrete categories of carbide grade for cutting tools

1.Grade P carbides are mainly divided into sub-grades P01, P10, P20, P30, and P40. The primary components include TiC and WC as the base, utilizing Co (Ni+Mo, Ni+Co) as a binder for carbides or coated alloys. Grade P carbides are primarily used for machining long chip materials such as steel, cast steel, and long-chipping malleable cast iron.

2.Grade M carbides are mainly divided into sub-grades M01, M10, M20, M30, and M40. The main components are WC as the base, with Co as a binder and a small amount of TiC (TaC, NbC) added for carbides or coated alloys. Grade M carbides are mainly used for machining general alloy materials such as stainless steel, cast steel, manganese steel, malleable cast iron, alloy steel, and alloy cast iron.

3.Grade K carbides are mainly divided into sub-grades K01, K10, K20, K30, and K40. The primary components are WC as the base, using Co as a binder and adding a small amount of TaC and NbC for carbides or coated alloys. Grade K carbides are primarily used for machining short chip materials such as cast iron, chilled cast iron, short-chipping malleable cast iron, and gray iron.

4.Grade N carbides are mainly divided into sub-grades N01, N10, N20, and N30. The main components are WC as the base, using Co a binder and adding a small amount of TaC, NbC, or CrC for carbides or coated alloys. Grade N carbides are mainly used for machining non-ferrous metal materials such as aluminum, magnesium, plastics, and wood.

5.Grade S carbides are mainly divided into sub-grades S01, S10, S20, and S30. The primary components are WC as the base, using Co as a binder and adding a small amount of TaC, NbC, or TiC for carbides or coated alloys. Grade S carbides are mainly used for machining heat-resistant and high-quality alloy materials containing nickel, cobalt, and titanium.

6.Grade H carbides are mainly divided into sub-grades H01, H10, H20, and H30. The main components are WC as the base, using Co as a binder and adding a small amount of TaC, NbC, or TiC for carbides or coated alloys. Grade H carbides are mainly used for machining hard chip materials such as quenched and hardened steel and chilled cast iron.

Carbide?Grades for Geological and Ore Tools

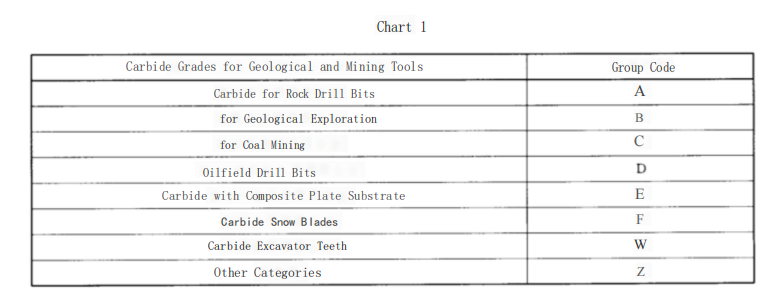

The characteristic code for carbide?grades used in geological and ore tools is represented by the letter “G,” and the group codes include 05, 10, 20, 30, 40, 50, and 60. The classification codes are A, B, C, D, E, F, W, and Z. The corresponding classifications for the classification codes are as follows:

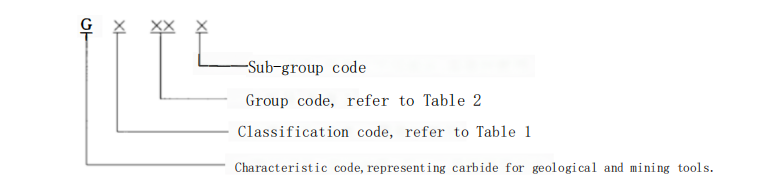

The representation rules for carbide?grades used in geological and ore tools primarily consist of characteristic codes, classification codes, group codes, and sub-group codes. An example is shown in the diagram below:

The main components of carbides used in geological and ore tools are based on WC, with Co as a binder, and the addition of trace elements for carbides or coated alloys. The identification of carbide?grades for geological and ore tools primarily involves testing various indicators such as element composition, Rockwell hardness, Vickers hardness, flexural strength, and metallographic structure (porosity, non-combined carbon, macroscopic pores). For these carbides, the recommended alloy performance under operating conditions is primarily assessed based on indicators such as wear resistance and toughness.

Cabide Grades for Wear-Resistant Parts

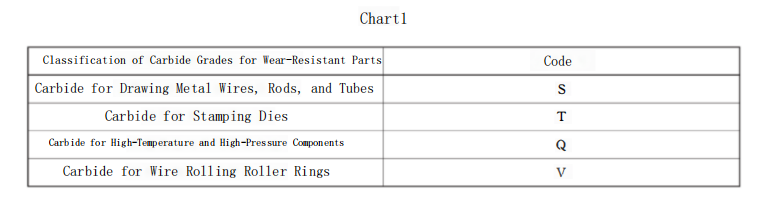

The characteristic code for carbide?grades used in wear-resistant parts is represented by the letter “L,” and the classification codes include S, T, Q, and V. The carbide?types represented by the classification codes are as follows:

The group codes for carbide?grades used in wear-resistant parts are respectively S: 10, 20, 30, 40; T: 10, 20, 30; Q: 10, 20, 30; V: 10, 20, 30, 40. The representation rules include characteristic codes, classification codes, group codes, and sub-group codes.

The main components of carbides used in wear-resistant parts are based on WC, with Co (or Co+Ni) as a binder, and the addition of trace elements for carbides or coated alloys. The identification of carbide?grades for wear-resistant parts primarily involves testing various indicators such as element composition, Rockwell hardness, Vickers hardness, flexural strength, and metallographic structure (porosity, non-combined carbon, macroscopic pores).