Original Quality Issues of the Cutting Tools

Due to the weak quality awareness of some cutting tool manufacturers, the tools produced have some quality issues, such as:

(1) The most obvious quality issue is the unexpected fracture of the ???? body due to poor quality of the tool body material and non-standard heat treatment.

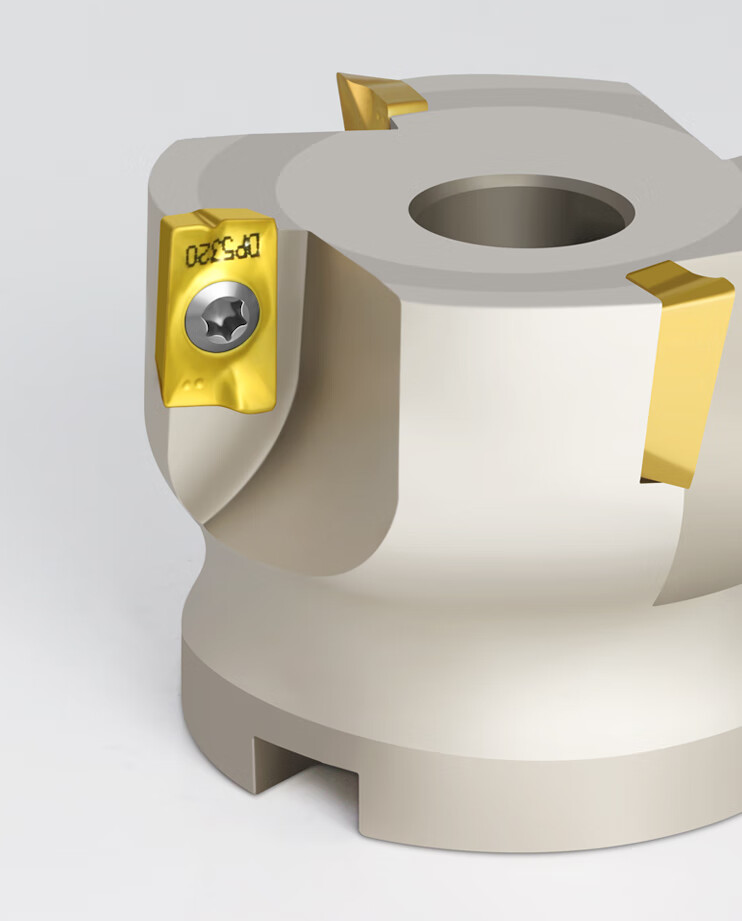

(2) Issues such as chip adhesion, thermal cracking of the cutting edge, and severe tool breakage due to improper selection of the insert grade. Each insert grade is suitable for specific machining materials and cutting conditions, and generally, they can be selected based on the performance and application of the carbide grade. However, in practice, the selection often does not follow the regulations, allowing for a great deal of flexibility.

(3) Structural problems. Improper cutting angles, poor chip evacuation, too many teeth, poor strength, and unbalanced cutting forces are all hidden dangers that can lead to abnormal damage of the cutting tools. These factors are closely related to the manufacturing experience and technical level of the tool manufacturers.

Issues Related to Tool Usage

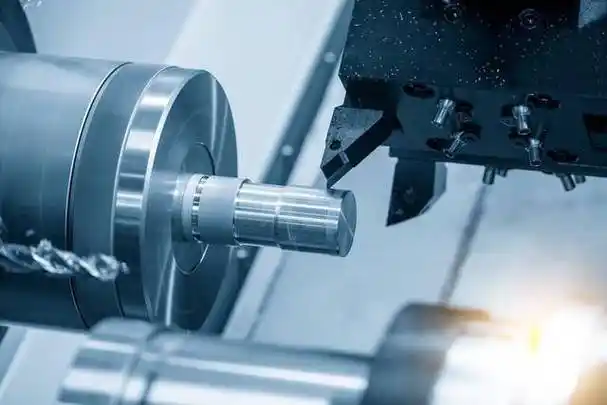

When indexable carbide cutting tools are used for certain finishing operations (such as precision boring or precision milling), the experience and technical level of the user are not highly demanding. However, when used for rough machining, higher requirements are needed. Tool-using manufacturers may cause abnormal damage to the tools, increase tool costs, and affect machining efficiency due to a lack of corresponding experience and technology. For example:

Tool breakage due to machine stalling

If the tool diameter is too large, the number of teeth is too dense, or the feed rate is too high, it can cause the machine’s power to be insufficient, leading to machine stalling and tool breakage, which is one form of abnormal tool damage. Therefore, considering the machine’s power capacity is a primary condition for cutting operations.

Cutting Fluid Issues

Cutting fluid plays a role in cooling, lubricating, cleaning, chip evacuation, and improving the quality of the machined surface during the machining process. However, cutting operations have different requirements for the properties, flow rate, and pressure of the cutting fluid. Whether to use cutting fluid depends on the machining conditions; it is not correct to assume that cutting fluid always has a beneficial effect. For example, if cutting fluid is added in the middle of cutting with an indexable carbide end mill, it will certainly damage the insert.

Poor rigidity of the process system

Due to the vibration of the process system, the loosening between the connecting components can occur, and if not inspected and discovered in a timely manner, it can lead to tool breakage. If the user is unaware that the insert is damaged and continues to use it, it will inevitably result in damage to the tool body.

Using a milling cutter with unequal pitch is one method to reduce vibration and improve cutting stability.

Improper selection of cutting parameters

Indexable carbide cutting tools require different cutting speeds and feed rates under different cutting conditions. Generally, tool manufacturers will provide recommended values that have been proven reasonable and reliable through cutting experiments. Blind use will inevitably lead to abnormal damage to the tools. For example, when a milling cutter engages with the workpiece, the cutting parameters should be appropriately reduced to prevent sudden impacts that could cause the milling cutter’s edge to break.

Issues caused by fastening screws

Because screws are small and relatively inexpensive to replace, their importance in the machining process is often not given sufficient attention by users. Some users, when installing inserts, use sleeves or other means to increase the torque, resulting in excessive pre-stress on the screws, making it impossible to loosen and replace the insert again, leading to the scrapping of the tool body. Sometimes, users mix up screw models, resulting in inappropriate clamping force. Others fail to conduct periodic inspections or replace damaged screws in a timely manner, creating potential safety hazards.

Exceeding the Scope of Use

Different types of indexable carbide cutting ????s have their respective scope of use. Users must follow the guidelines to avoid abnormal damage. For example, indexable carbide spot drills are generally suitable for machining holes with a depth less than three times the diameter. If the depth is too great, it can damage the tool due to poor chip evacuation. Moreover, the surface to be machined must be flat, without grooves or protrusions; otherwise, vibration will occur at the moment of drilling, leading to edge breakage or even damage to the tool body. If there is a pre-drilled hole in the part, its diameter should not exceed 1/4 of the drill bit’s diameter; otherwise, the feed rate should be reduced, and so on.

Issues with the Workpiece Material

In addition to considering the above factors, sometimes there is still a high rate of tool breakage. At this point, one should consider whether the condition of the blank is poor, or if there is a severe sand inclusion situation, and methods to improve the condition of the blank should be considered.

Some Suggestions in Conclusion

(1) For users, it is advisable to purchase indexable carbide cutting tools produced by regular manufacturers, as these manufacturers provide technical documentation, usage instructions, and comprehensive after-sales service, generally ensuring that there are no original quality issues with the products.

(2) The using manufacturers should organize professionals to provide technical training on the use of indexable carbide cutting tools for operators, and constantly inspect and remedy any unfavorable factors that may arise during the entire machining process to avoid unnecessary losses and improve production efficiency.

The successful use of indexable carbide cutting tools not only depends on the quality of the tools themselves but is also related to every aspect of the entire machining system; for example, the performance of the machine tool, the reliability of workpiece clamping, the rigidity of the tool holder system, the rationality of blade selection, and the correct selection of cutting parameters all affect the machining results. Only by using the cutting tools correctly and reasonably can one avoid abnormal damage, improve machining efficiency, and achieve the maximum economic benefits.