In the lathe for non turning processing, is the lack of equipment and other factors have to do it, but in this process, the intelligent working people found that after the transformation of the machine tool, can complete a lot of efficient and high-quality processing.

In the milling process on the lathe, there is a kind of whirlwind milling thread, which is one of them.

What is whirlwind milling

Because of its high milling speed (up to 400m / min) and high machining efficiency, compressed air is used for chip removal and cooling. In the process of machining, cutting spatter is named after whirlwind.

Whirlwind milling thread is a method that whirlwind milling head is used to process thread, which only needs one cutting.

1.Determination process of whirlwind milling tool

2.Determine part shape

3.Determine tool shape according to parts

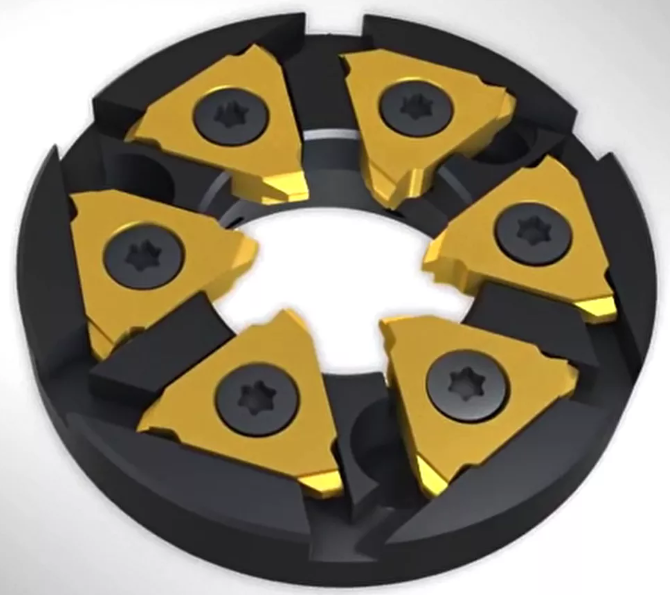

4.Make the corresponding blade

There are several companies specialized in the production of thread milling inserts, such as Camex, NTK, haoen and Fengyi, which are commonly used in domestic cyclone milling equipment.

5.Install the blade on the cutter?head

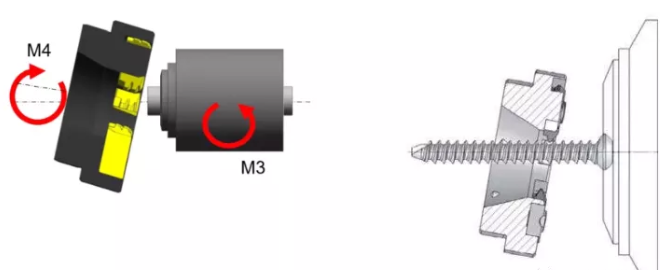

- Five movements of whirlwind milling

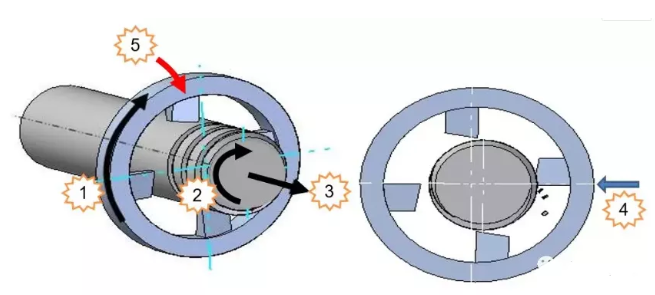

- After the whirlwind milling is matched with the lathe, five machining movements need to be completed in the processing process

- The cutter head drives the carbide forming cutter to rotate at high speed (main motion)

- Qualification

- Express alarm about

- The lathe spindle drives the workpiece to rotate slowly (auxiliary motion)

- The whirlwind milling machine moves along the axial direction of the workpiece according to the pitch or lead of the workpiece (feed motion)

- The whirlwind milling is driven by the carriage in the lathe to carry out radial movement (cutting movement)

- The spiral milling angle can be adjusted within a certain range. (rotational motion)

Necessary equipment for whirlywind milling

Equipment structure of whirlwind mill:

- Medical industry (implants).

Medical industry, medical bone nail, etc

- Automotive industry.

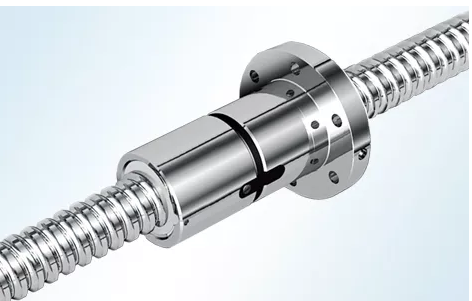

Automobile automatic transmission shaft, such as transmission shaft on automatic seat, etc

- Machine tool industry and others.

Machine tool screw with whirlwind milling processing, will have a high efficiency

Whirlwind milling process

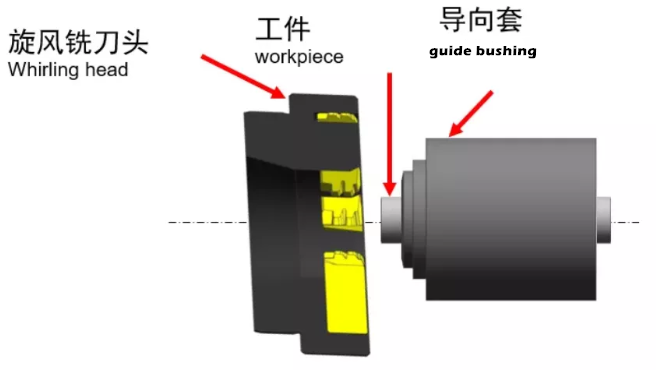

1. It is composed of whirlwind milling cutter head, workpiece and guide sleeve.

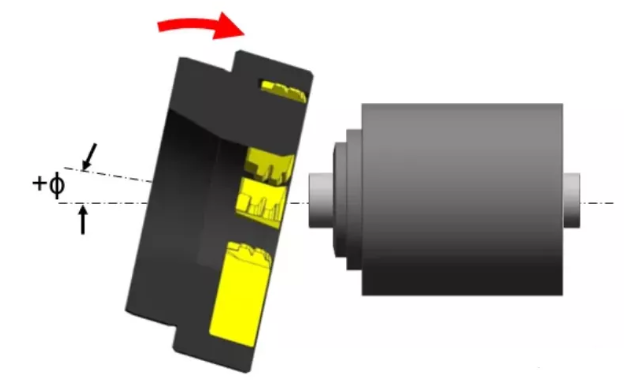

2. Adjust the installation deflection angle according to the screw angle of the thread.

The installation deflection angle determines the size of thread pitch, and large installation angle determines the processing of large pitch thread.

3. Down milling

The rotation direction of the whirlwind milling cutter head is opposite to that of the machine tool spindle (part), so it can process good surface quality. On the contrary, it is reverse milling, and the surface quality is poor.

Advantages of whirlwind milling

Advantages of whirlwind milling thread cutting:

1. High processing efficiency, higher than the traditional turning processing efficiency! Up to 10 times.

2. The product is formed by one knife, and the eccentric cutting does not need to withdraw the cutter.

3. Without changing the structure of lathe, the angle of helix can be adjusted, and the installation is convenient.

4. The surface roughness can reach Ra0.8 μ m or even higher, and the machining accuracy can be improved by 2 levels.

5. The programming method is simple and fast, forming blade, high positioning accuracy of blade and blade groove, reducing the technical requirements of workers.

Whirlywind milling can achieve dry cutting, heavy cutting, difficult to machine materials and ultra-high speed cutting, with low power consumption. The surface roughness can reach Ra0.8 μ M. Lathe spindle speed is slow, so the machine tool motion accuracy is high, dynamic stability is good, is an advanced thread processing method.