How to Solve Burr Issues

Chemical Deburring

Chemical deburring utilizes chemical energy for processing. Chemical ions adhere to the surface of the parts, forming a film with high electrical resistance and low conductivity, which protects the workpiece from corrosion. Since metalworking burrs are higher than the surface, they can be removed through chemical action. This method of deburring is widely used in fields such as pneumatic, hydraulic, and construction machinery.

High-Temperature Deburring

First, place the parts that need deburring into a tightly sealed chamber, then introduce the chamber into a hydrogen-oxygen mixed gas environment with a certain pressure. Ignite the mixed gas to cause an explosion, releasing heat to burn off the burrs without damaging the parts.

Roll Grinding Deburring

Place the parts and abrasive materials into a closed drum. As the drum rotates, a dynamic torque sensor, along with the parts and abrasive, generates a grinding action to remove metalworking burrs. Abrasives can be made of quartz sand, wood chips, alumina, ceramics, and metal rings, among others.

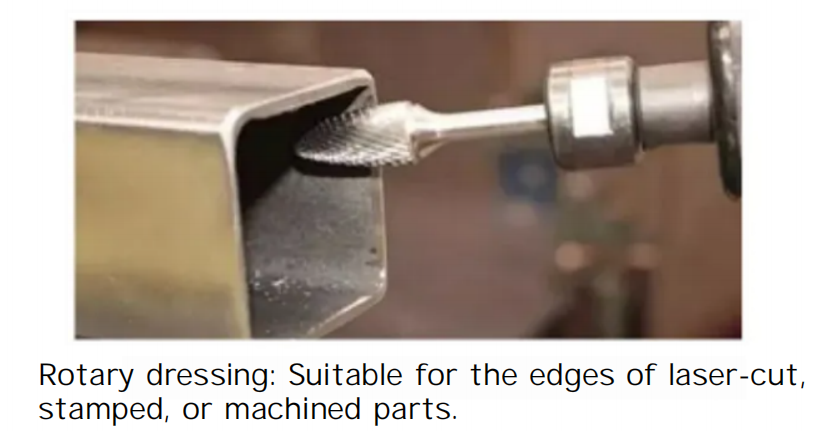

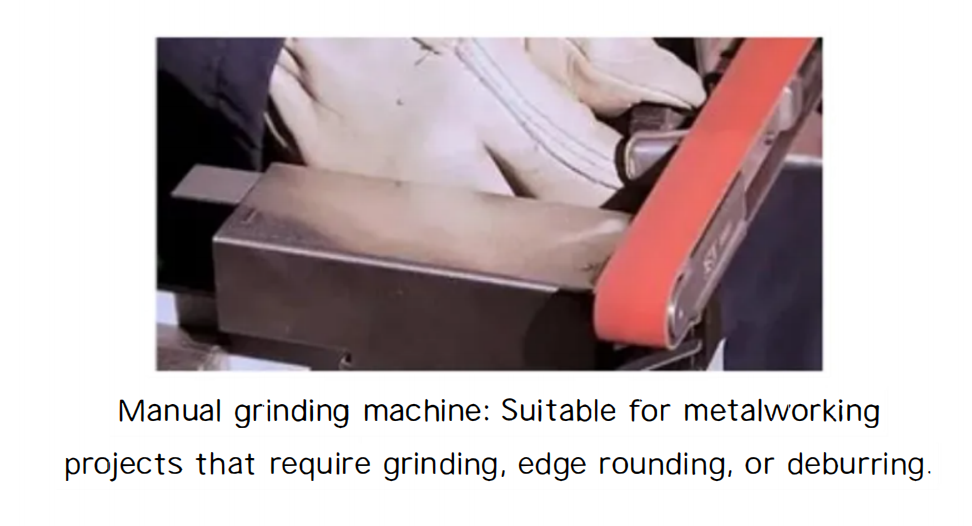

Manual Deburring

This method is more traditional and also the most time-consuming and labor-intensive. It mainly involves manually grinding with tools such as steel files, sandpaper, and grinding heads. The most commonly used tool in production now is the trimming knife.

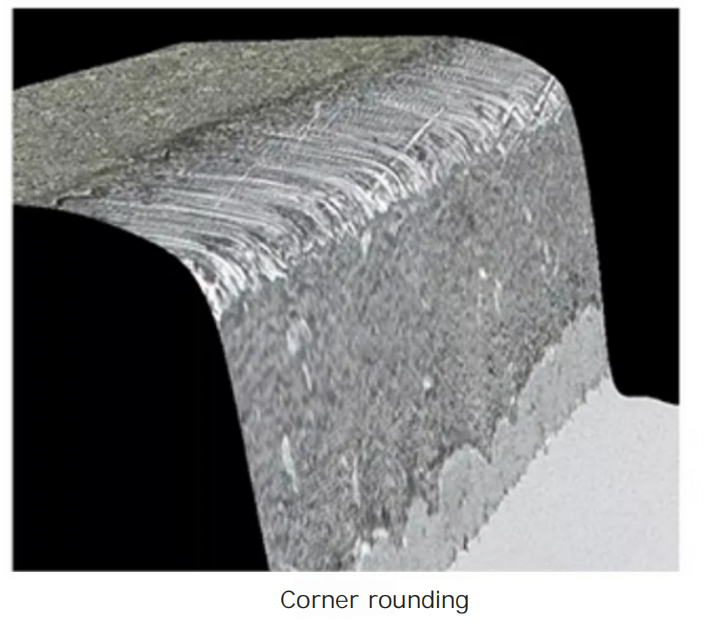

Process Deburring – Edge Rounding

Edge rounding can refer to any action that removes the sharpness from the edges of metal components. However, it is typically associated with creating a radius on the edges of parts.

Edge rounding is not simply about removing sharpness or deburring, but about breaking the edges of metal components to improve their surface coating coverage and protect them from corrosion.

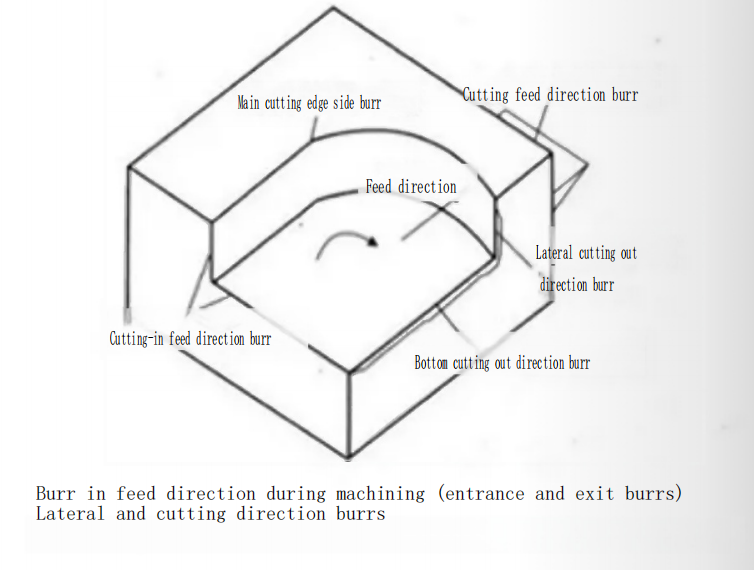

Removing metalworking burrs in Milling Parts

In milling parts, deburring is more complex and costly, as multiple metalworking burrs are formed at different positions with varying sizes during milling. It is particularly important to select the correct process parameters to minimize metalworking burr size.

Main Factors Affecting Burr Formation in End Milling

① Milling parameters, milling temperature, and cutting environment, among others, have a certain impact on burr formation. Some key factors, such as feed rate and milling depth, are reflected through the plane cutting angle theory and the Edge Engagement Sequence (EOS) theory.

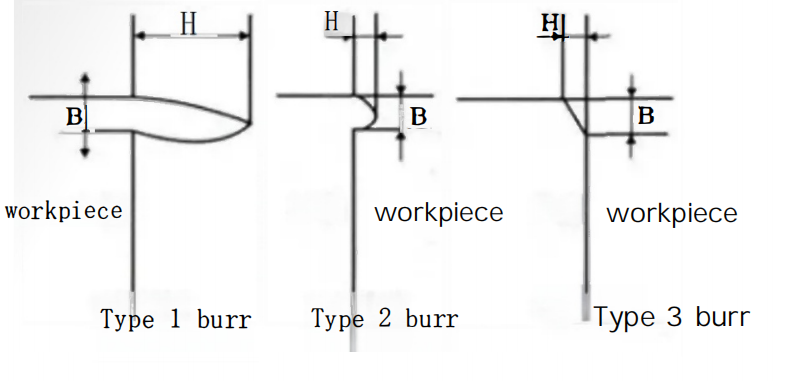

② The better the plasticity of the workpiece material, the more likely it is to form Type I burrs. In the processing of brittle materials with end milling, if the feed rate or the plane cutting angle is large, it is conducive to the formation of Type III burrs (deficits).

③ When the angle between the end face of the workpiece and the machined plane is greater than a right angle, the increased support stiffness of the end face can suppress machining burr formation.

④ The use of cutting fluid is beneficial for extending tool life, reducing tool wear, lubricating the milling process, and thereby reducing the size of burrs.

⑤ Tool wear has a significant impact on machining burr formation. When the tool wears to a certain extent and the tip radius increases, not only does the burr size in the tool retracting direction increase, but type burrs may also form in the tool cutting-in direction.

⑥ Other factors, such as tool material, also have a certain impact on burr formation. Under the same cutting conditions, diamond tools are more effective in suppressing metalworking burr formation than other types of tools.

How to Effectively Handle Burrs Generated During Tool Retraction

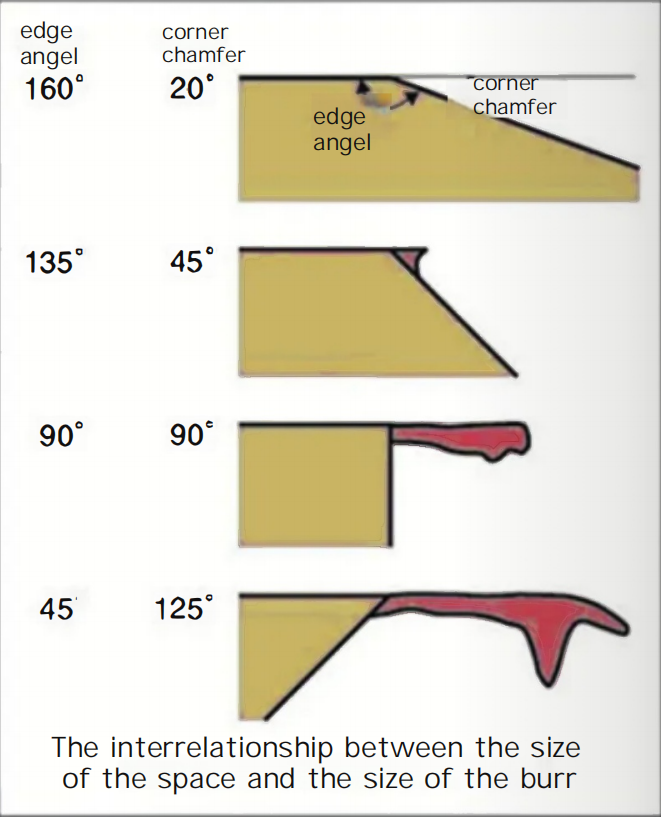

To suppress burrs generated during tool retraction, eliminating the space where burrs are produced is an effective method. For example, measures such as chamfering can be taken to reduce the space before retracting the tool.

Using appropriate cutting conditions to suppress machining burrs should aim to minimize the amount of cutting residue, and it is necessary to select the most suitable tool and cutting conditions. Use tools with a large rake angle and sharp cutting edges. Increase cutting speed to improve cutting characteristics. Especially during finish cutting, it is essential to use the minimum cutting depth and feed rate.

The size of the space between the tool and the workpiece determines the size of the burrs. Let’s take a look at the relationship diagram below.

摘要

In fact, during the machining process, burrs are inevitable, so it is best to address the metalworking burr issue through process improvements, avoiding excessive manual intervention. Using chamfering end mills can reduce the space where burrs are produced, effectively remove burrs, and is also a very suitable method for clearing burrs.