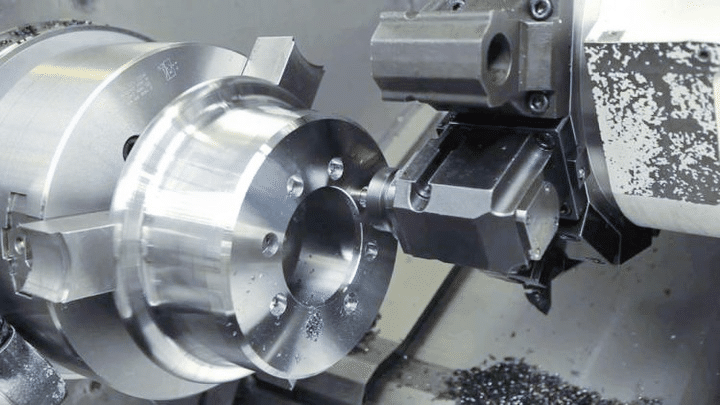

At present, the vast majority of metal cutting is carried out by wet method mainly using cutting fluid, because cutting fluid has the functions of cooling, lubrication, cleaning and chip removal, which plays an important role in prolonging the service life of cutting tools and ensuring the processing quality, A series of negative effects caused by cutting fluid are also concerned. Dry cutting is to protect the environment and reduce processing costs, consciously do not use cutting fluid, cutting in the absence of cutting fluid conditions. However, dry cutting is not simply to stop using cutting fluid, but to ensure high efficiency, high product quality, high tool life and the reliability of the cutting process at the same time of stopping using cutting fluid, which requires the use of excellent dry cutting tools, machine tools and auxiliary facilities to replace the role of traditional cutting fluid in order to achieve the true sense of dry cutting.

Characteristics of dry cutting

1. There will be no safety accident and quality accident related to cutting fluid.

2. The chip is clean and pollution-free, easy to recycle and dispose, and will not produce environmental pollution.

3. The separation device of cutting fluid and chip and corresponding electrical equipment are omitted. The structure of the machine tool is compact and the floor area is reduced.

4. Cutting fluid transmission, recovery, filtration and other devices and the corresponding costs are saved, the production system is simplified, and the production cost is reduced.

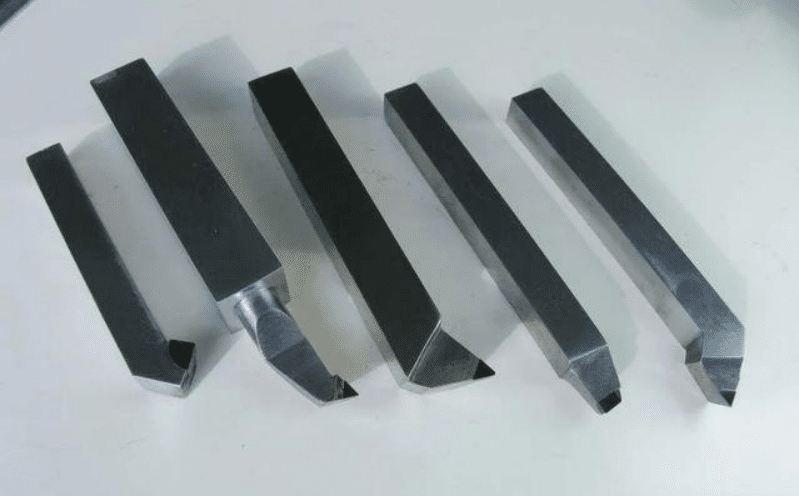

Tool material selection

1. ultrafine cemented carbide materials. The ultra fine cemented carbide can improve the toughness of the ordinary cemented carbide, and has good wear resistance and high temperature resistance. It is suitable for dry milling and drilling.

2. ceramic materials. It has good red hardness, but the thermal toughness is not good, so it is suitable for dry turning and not for dry milling.

3. CBN materials. High hardness, good heat conductivity, good chemical stability at high temperature, can be used to replace grinding with turning.

4. PCD material. The hardness is very high and the heat conductivity is good. It is suitable for dry processing of copper, aluminum and aluminum alloy.

Dry cutting mode

The key of dry cutting in machining is to find a way to replace cooling and lubrication. There are two successful dry cutting methods: high speed dry cutting and low temperature cold air cutting.

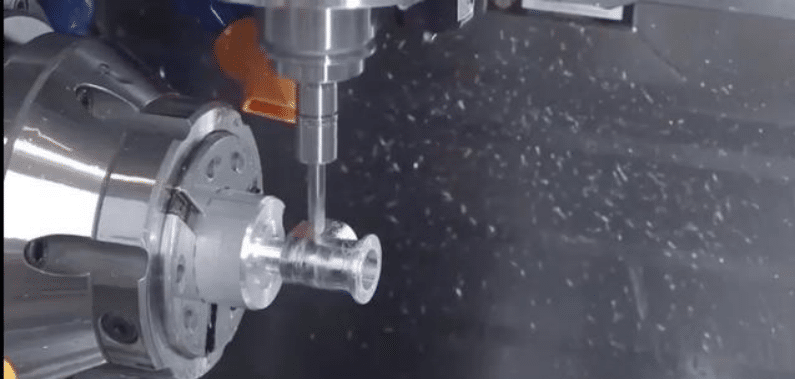

High speed dry cutting

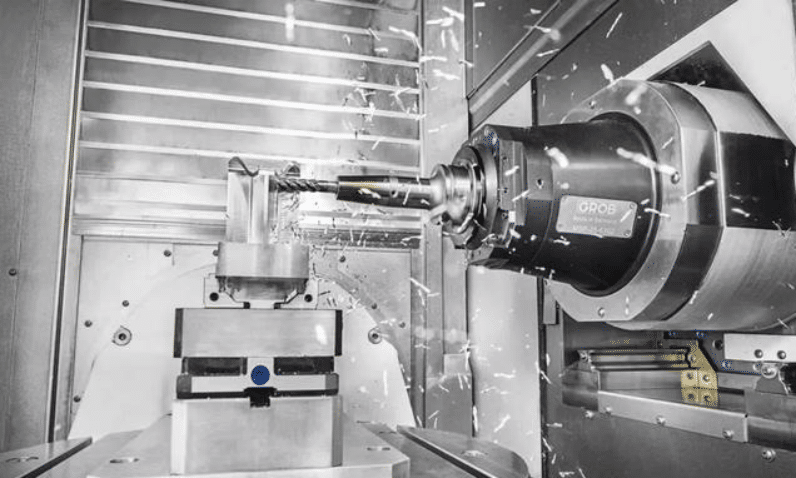

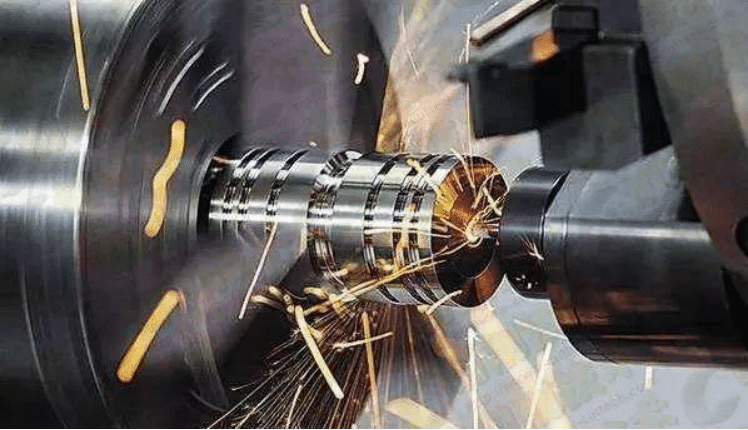

The machining method adopts high cutting speed without cooling and lubricating oil. Suitable cutting conditions must be selected for dry cutting. First of all, high cutting speed is used to shorten the contact time between the tool and the workpiece, and then compressed air or other similar methods are used to remove the chips to control the temperature of the working area.

Because it saves the process of oil chip separation, no cooling lubricating oil tank, oil chip separation device and corresponding electrical equipment, the structure of the machine tool is compact. Moreover, this method greatly improves the processing environment; Processing costs are also greatly reduced. In order to further prolong the tool life and improve the workpiece quality, 10-1000ml lubricating oil can be used for micro lubrication every hour in the dry cutting process. The chip produced by this method can be considered as dry chip, and the accuracy, surface quality and internal stress of the workpiece are not affected negatively by trace amount of lubricating oil.

Low temperature cold air cutting

This cutting method is a kind of processing method which uses – 10 ~ – 100 ℃ cold air and a very small amount of vegetable oil instead of cooling and lubricant cooling. It is found that in the process of metal cutting, if only a very small amount of vegetable oil with good lubricating effect and no oxidation is provided to the processing point, the processing point will lose its lubricity due to high temperature. If the cold air (- 10 ~ – 100 ℃) is provided to the processing point, the high temperature of the processing point can be prevented and the above situation can be avoided. The cutting performance is greatly improved in cold air cutting. The test shows that the performance of cold air cutting and grinding is more than 2 times higher than that of oil cutting and grinding.