The cutting fluid used in machining has two functions:

1. Cooling effect

2. Lubrication

Common cutting fluids are generally divided into two categories due to different emphasis surfaces:

One is aqueous solution mainly cooling:

The other is mainly lubricating oil.

The cooling based aqueous solution is generally an emulsion like milk seen in the factory. It is used for rough machining in order to increase the cooling effect and improve the service life of tools.

Lubricating oil, such as oil for full loss system, kerosene, oleic acid and rapeseed oil, is used to increase the lubrication effect, ensure the surface roughness of the machined surface and reduce tool wear.

Cutting fluid can be used at high speed and low speed. Oil for full loss system is a cutting fluid used at low speed.

For example, in manual tapping, the oil used in the full loss system is used as the cutting fluid. It should be noted that when using oil for full loss system, if the temperature is higher than 250 ℃, its cooling and lubrication effect is not as good as that of water.

The cutting of machine tools is carried out under high temperature and high pressure on many occasions. Under high temperature and high pressure, cutting fluid containing extreme pressure agent should be used. So what is extreme pressure agent? Extreme pressure agent is a substance that can maintain lubrication under high temperature and high pressure.

General extreme pressure agents include sulfur, chlorine, molybdenum disulfide, oleic acid, graphite, etc. When extreme pressure agent is added to the cutting fluid, it is the cutting fluid used at high temperature.

The current machining situation in the world is that the understanding of the role of cutting fluid is not high enough, and the role of cutting fluid is not fully utilized. In many machining occasions, the role of cutting fluid is the same as that of cutting tools, which is equally important. It is impossible to leave any one.

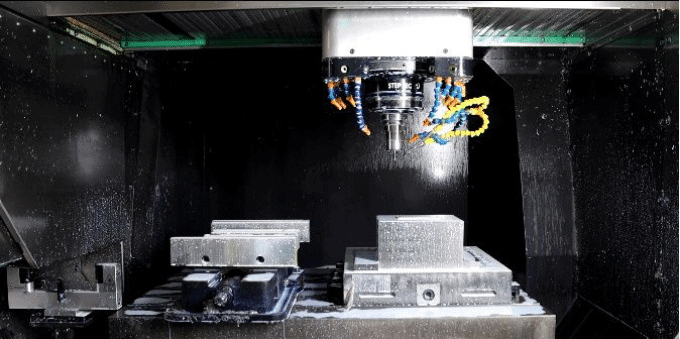

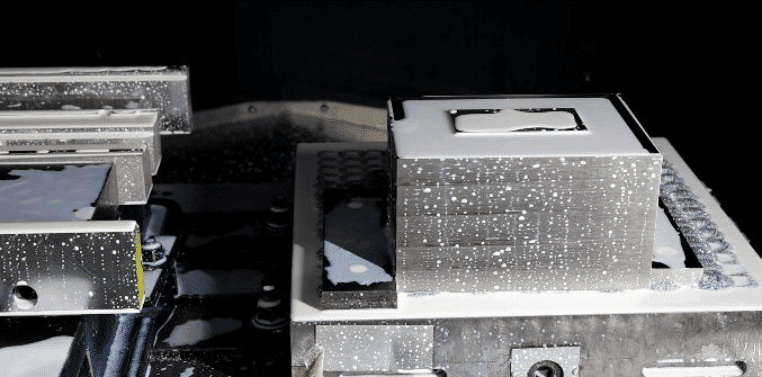

In terms of cooling, the current situation is: when machining parts in NC milling center and NC machining center, the flow of cutting fluid is much larger than that of ordinary lathe, and the large flow takes away a lot of heat, so as to make the cooling environment of the tool much better and make the tool have a high speed.

The flow of cutting fluid used in ordinary lathe is relatively small and the cooling environment is relatively poor. It can only run at a lower speed for cutting. If a large flow of cutting fluid is used for cooling on an ordinary lathe, it will cause splashing of cutting fluid and become generally not used.

In terms of lubrication, many processors generally do not pay attention to the role of cutting fluid, but blindly pay attention to the role of cutting tools, pay more attention to the cutting angle of cutting tools, and do not pay attention to the cooling and lubrication during cutting, resulting in the wear of the used tools in a very short time, and the number of repeated grinding increases, so that the tools will be worn and scrapped in a short time.