Cast iron and steel may look very similar on the surface, and they have different advantages and disadvantages from production to application. Understanding these advantages and disadvantages, and choosing the right ones may mean unforgivable differences between strength and durability and cracked or deformed parts, which can quickly lose luster.

Carbon content

Both iron and steel are ferrous metals mainly composed of iron atoms. In manufacturing, however, it’s not that simple. There are many different alloys and grades. In fact, carbon composition is the main difference between cast iron and steel. Cast iron usually contains more than 2.5% carbon, while cast steel usually contains 0.2-0.6% carbon.

Machinability

Depending on the final application, the casting may need to be machined to achieve a specific tolerance or to create the required finish. Machinability is a measure of the machinability or grindability of a given material; some materials are more difficult to machine than others. Generally speaking, metals with high alloy added to improve mechanical properties have low machinability.

Cast iron is usually easier to machine than steel. The graphite structure in cast iron is more likely to fracture in a more uniform way. Hard iron, such as white iron, is difficult to process because of its brittleness.

At the same consistency, steel is not easy to cut, and will cause more tool wear, resulting in higher production costs. Hardened steel or steel with high carbon content will also increase tool wear. Softer steel may not be better, however, mild steel, although softer, may stick and be difficult to use.

karakteristik

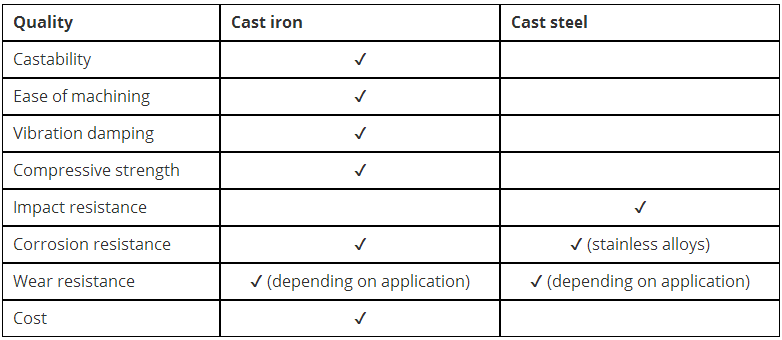

The following table outlines the quality of each ingredient material. Although there are many different types of steel to consider, this table focuses on the two most common metal forms of gray iron and carbon steel.

Castability

People who work with liquid iron and steel will soon find that they are very different in castability and shrinkage. Cast iron is relatively easy to cast because it is easy to pour and does not shrink as much as steel. This means that it will be easy to fill complex voids in the mold and require less molten material to complete. This fluidity makes cast iron an ideal metal for buildings or ornate iron structures such as fences and street furniture.

The internal structure of castings does not normally cool evenly. The external area and the thinner part of cast iron will cool and contract at different rates, while the internal area and the thicker part usually produce internal tension or stress, which can only be relieved by heat treatment.

For these reasons, more attention and inspection are needed in the whole casting process of cast steel

bas?n? dayan?m?

Compressive strength is the ability of a material to withstand forces that reduce the size of an object. This is the opposite of the force that pulls the material apart. Compressive strength is beneficial in mechanical applications, in which pressure and seal are factors. Generally, cast iron has better compressive strength than steel.

Impact resistance

So far, the use of cast iron seems to have an advantage over the use of steel, but steel has a significant advantage: impact resistance. Steel can withstand sudden impact without bending, deformation or fracture. This is because of its toughness: it can withstand high stress and high strain.

Non plastic strength is easy to cause brittle material fracture. Cast iron is a typical representative of strength and ductility. Because of its brittleness, the application of cast iron is limited.

At the same time, the high plastic or non-destructive deformation ability is not useful in the case of no strength to withstand significant impact.

While iron may be easier to use in most casting applications, steel has the best combination of strength and ductility, making it extremely tough. The impact resistance and all-round bearing capacity of steel make it suitable for many mechanical and structural applications

Corrosion resistance

Iron has better corrosion resistance than steel. However, when unprotected, both metals oxidize in the presence of water. If there is enough time, they will eventually peel off. Therefore, in order to prevent corrosion, it is recommended to use paint or powder coating to protect the steel surface. Any chips or cracks exposed to the underlying metal can cause corrosion, so regular maintenance is important for the coated metal. If corrosion resistance is an important factor, alloy steel may be a better choice, especially for stainless steel, where chromium and other alloys are added to prevent oxidation.

Machinability

Depending on the final application, the casting may need to be machined to achieve a specific tolerance or to create the required finish. Machinability is a measure of the machinability or grindability of a given material; some materials are more difficult to machine than others. Generally speaking, metals with high alloy added to improve mechanical properties have low machinability.

Cast iron is usually easier to machine than steel. The graphite structure in cast iron is more likely to fracture in a more uniform way. Hard iron, such as white iron, is difficult to process because of its brittleness.

At the same consistency, steel is not easy to cut, and will cause more tool wear, resulting in higher production costs. Hardened steel or steel with high carbon content will also increase tool wear. Softer steel may not be better, however, mild steel, although softer, may stick and be difficult to use.

cost

Cast iron is usually cheaper than cast steel because of the low cost of materials, energy and labor required to produce the final product. Raw steel is more expensive to purchase and requires more time and effort to cast. However, the long-term use and replacement cost should be considered when designing casting products. In the long run, parts with higher manufacturing costs may end up with lower costs.

Steel also has many forms of prefabrication, such as plates, rods, bars, tubes, and beams, which can generally be machined or assembled to suit specific applications. Manufacturing existing steel products may be a cost-effective option, depending on the product and quantity required.

Wear resistance

Cast iron usually has better mechanical wear resistance than steel, especially in the case of friction and wear. The higher graphite content in cast iron produces a graphite dry lubricant, which makes the solid surfaces slide with each other without reducing the surface quality.

Steel is easier to wear than iron, but it can still resist certain types of wear. Some alloy additives can also improve the wear resistance of steel.

Species of cast iron and steel

We have compared the quality of the most basic form of cast iron (gray iron) with that of cast steel (mild steel or carbon steel), but the specific composition and phase structure of steel can greatly affect the mechanical properties. For example, carbon in standard gray iron is in the form of sharp graphite flakes, while ductile iron has more spheroidal graphite structure. The flake graphite makes the gray iron brittle, while the round graphite particles in the nodular iron improve the toughness, making it more suitable for impact resistant applications.

Alloys can be added to iron and steel to obtain the required properties. For example, manganese can increase toughness, while chromium can improve corrosion resistance. Different carbon content is also a reason to distinguish low carbon steel, standard steel and high carbon steel. High carbon content will make the material harder.