When we talk about the master of the machining center, our first impression is that he is a master with the ability to program, set the tool, debug, clamp and process the parts. In fact, any industry is the same, to become a master of its own needs is accumulated over time, step-by-step process, and can not be achieved overnight. As far as the operation of CNC machining center is concerned, there are many methods and skills that can make us get twice the result with half the effort, but the operation is still too tired, so we have to do programming sooner or later

Programming

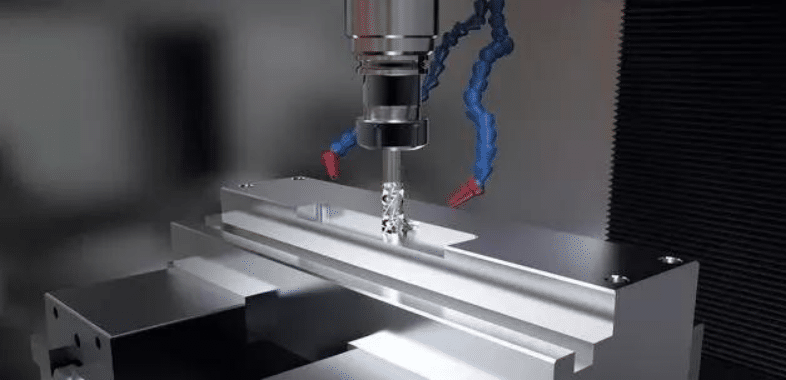

CNC machining center requires high accuracy of products. When programming, we should fully consider two aspects, one is the processing sequence, the other is the parameters, such as speed, feed, cutting depth.

The processing sequence is generally as follows: first drill, then flat end. This can prevent shrinkage during drilling; First rough machining, then fine machining; The first machining tolerance is large, and the last machining tolerance is small.

According to the hardness of the material, we choose reasonable speed, feed rate and cutting depth: carbon steel materials choose high speed, high feed rate and large cutting depth. Cemented carbide choose low speed, low feed, small cutting depth. Titanium alloy has low speed, high feed rate and small cutting depth.

![The 4 Have-to-know Skills if you Wanna Get the Job as a Lathe Operator 4 The 4 Have-to-know Skills if you Wanna Get the Job as a Lathe Operator 4]() Direct knife setting

Direct knife setting

First, select the center of the right end face of the part as the tool setting point, and set it as the zero point. After the machine returns to the zero point, each tool that needs to be used will set the center of the right end face of the part as the zero point; When the tool contacts the right end face, input Z0 and click measure, the measured value will be automatically recorded in the tool compensation value, which means that the z-axis tool setting is good, the x-axis tool setting is trial cutting tool setting, and the outer circle of the part is less with the tool. Input X20 to measure the outer circle of the part to be turned (for example, X is 20mm). Click measure, the tool compensation value will automatically record the measured value, and then the x-axis is also good;

This direct tool setting method, even if the machining center is powered off, will not change the tool setting value after the call is restarted again. It can be used for mass production of the same part for a long time, and it does not need to reset the tool when the equipment is shut down.

![The 4 Have-to-know Skills if you Wanna Get the Job as a Lathe Operator 6 The 4 Have-to-know Skills if you Wanna Get the Job as a Lathe Operator 6]() Debugging

Debugging

After the parts are programmed, the trial cutting and debugging should be carried out after the tool is properly adjusted. In order to prevent the program errors and tool setting errors, resulting in the collision accident.

We should first simulate the machining of the empty stroke, and translate the tool to the right in the coordinate system of the machining center, which is 2-3 times of the total length of the part; Then start the simulation processing. After the simulation processing is completed, confirm that the program and tool setting are correct, and then start the processing of the parts. After the first part is processed, self check is carried out first to confirm that it is qualified, and then go to the full-time inspector for inspection. After the full-time inspector confirms that it is qualified, this means the end of debugging.

Knife collision prevention techniques

The impact of the tool in the machining center is very bad to the accuracy of the equipment, and the influence on different types of machine tools is different. Generally speaking, it has a great influence on the machine tools with low rigidity. Therefore, for high-precision machining center, collision must be eliminated absolutely. As long as the operator carefully and master certain anti-collision methods, collision can be prevented and avoided completely. There are only three reasons for the tool collision: one is the wrong input of the diameter and length of the tool; Second, the input error of workpiece size and other related geometric dimensions and the initial position positioning of workpiece are wrong; Third, the workpiece coordinate system of the machining center is set incorrectly, or the machine zero point is reset during the processing process, and the machine tool collision occurs mostly in the process of rapid movement of the machine tool. The collision at this time is also the most harmful and should be avoided absolutely.

In order to avoid the above collision, the operator should give full play to the functions of five functions when operating the machine tool. Observe whether the machine tool has abnormal action, sparks, noise and abnormal sound, vibration and coke smell. If any abnormal situation is found, the program shall be stopped immediately. The machine can not continue to work until the problem is solved.

The operation of CNC machining center is based on the basic operation, basic machining knowledge and basic programming knowledge of machine tool. The operation skill of CNC machine tool is not constant, it is an organic combination of the operator’s imagination and hands-on ability, and it is an innovative labor.