Article Source

Kareem, S. J., Wurood Asaad, M., & Al-Ethari, H. ?Enhancement of tribological properties of carbide cutting tools by ceramic coating deposition.?Heat Treatment and Surface Engineering,(2024).?6(1). https://doi.org/10.1080/25787616.2024.2331865

Аннотация

Coating by sol–gel deposition to modify the tribological properties of K10 carbide cutting insert was performed. The study examines the thermal and tribological characteristics of uncoated cutting inserts and the cutting inserts coated with TiO2/8YSZ and TiO2/15YSZ layers respectively. The TiO2/8YSZ and TiO2/15YSZ coatings had a hardness of 1151.6 and 1678.9 HV, respectively, and the TiO2/8YSZ and TiO2/15YSZ coated inserts had scratch hardness of 2.73 and 22.98 GPa respectively. Among the uncoated and coated inserts, the TiO2/15YSZ coated inserts had the lowest coefficient of friction and rate of wear. The TiO2/8YSZ coated insert had a lower thermal conductivity when compared to TiO2/15YSZ coated insert and uncoated carbide cutting insert (10.3 vs. 14.1, and 41.8 W/m.K). The thermal expansion coefficients of the 8YSZ layers, 15YSZ layers, and carbide cutting tool were 3.66*10?6, 3.546*10?6 and 14*10?6 K?1, respectively. The reasons for the enhancement of the tribological properties of the carbide cutting tools by the ceramic coatings are discussed.

Key Findings

Research Team: The team from the Department of Materials Engineering, University of Babylon, Iraq

Technical Approach: The research team deposited TiO?/yttria-stabilized zirconia (YSZ) multilayer ceramic coatings on K10 tungsten carbide inserts via the sol-gel method, systematically analyzing the effects of 8% and 15% yttrium contents (8YSZ vs. 15YSZ) on performance.

Key Data Highlights (with partial data from Figure 10)

Hardness and Scratch Resistance

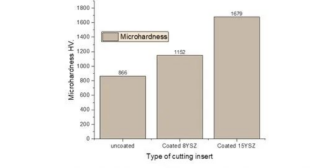

Microhardness: The 15YSZ-coated insert achieved 1,679 HV (uncoated insert: only 866 HV), a nearly 2-fold increase!

Scratch Hardness: The 15YSZ coating reached 22.98 GPa, significantly enhancing interfacial bonding strength.

Friction and Wear Resistance of Tested Tools

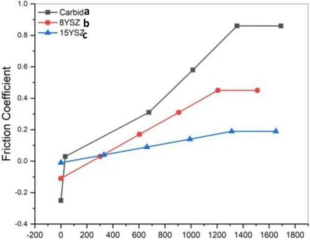

Friction Coefficient: The 15YSZ coating showed a coefficient of only 0.17, a 76% reduction compared to the uncoated insert (0.71) (Figure 12).The key data from the experiments are remarkable. In terms of hardness and scratch resistance, microhardness tests show that the 15YSZ-coated insert achieves an impressive 1,679 HV—nearly double the 866 HV of the uncoated insert. This means the coated insert can more effectively withstand high-intensity cutting, reducing tool wear. Scratch hardness tests further confirm the coating’s excellence: the 15YSZ coating’s 22.98 GPa value directly reflects a significant enhancement in interfacial bonding between the coating and substrate, akin to armoring the tool with a robust, well-adhered layer.

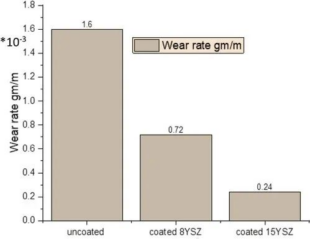

In the realm of friction and wear resistance, the experimental data are equally striking. The friction coefficient test chart (Figure 12) clearly shows that the 15YSZ coating has a coefficient of only 0.17—76% lower than the uncoated insert’s 0.71. This dramatic reduction enables smoother tool operation during cutting, minimizing energy loss from friction. Even more impressive, wear rate tests (Figure 14) reveal that the 15YSZ coating has a wear rate as low as 0.24×10?3 g/m—85% lower than the uncoated insert—significantly extending tool service life.

Figure 10. The micro hardness of uncoated insert and different coatings, and the images of indents produced on the surface of uncoated inserts and different coatings.

Figure 12. Coefficient of friction versus time of uncoated insert and the inserts coated by TiO2/8YSZ and TiO2/15YSZ coatings respectively.

Figure 14. Wear rate of the uncoated and coated inserts.

Technical Breakthrough

Low-Temperature Process Advantages

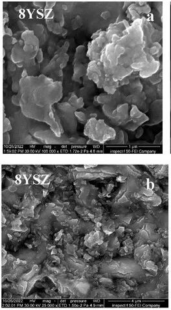

The sol-gel method completes coating deposition at a low temperature of 700°C, avoiding thermal damage to the substrate caused by traditional high-temperature processes while achieving high purity and uniformity (Figure 4).

Yttrium Content Regulation Mechanism

Grain Refinement: Increasing yttrium content from 8% to 15% inhibits grain growth and refines the coating structure (XRD shows stable cubic phase, Figure 3).

Performance Balance: High yttrium content enhances hardness and wear resistance but requires trade-offs with thermal conductivity (15YSZ has slightly higher thermal conductivity than 8YSZ).

In terms of thermal performance optimization, the 8YSZ coating exhibits unique advantages. With a thermal conductivity of only 10.3 W/m·K, it effectively blocks heat conduction generated during cutting, preventing tool performance degradation due to overheating. Meanwhile, the YSZ coating (3.5–3.6×10?? K?1) has a smaller difference in thermal expansion coefficient from the tungsten carbide substrate (14×10?? K?1), a feature that significantly reduces the risk of coating spalling caused by thermal stress and further enhances tool stability and reliability.

The technological breakthrough of this study is of milestone significance. First, the sol-gel method can complete coating deposition at a low temperature of 700°C. Compared with traditional high-temperature processes, this low-temperature process successfully avoids thermal damage to the substrate. As clearly shown in the FESEM images (Figure 4), the coating prepared by the sol-gel method features high purity and uniformity, with a dense and homogeneous structure, laying a solid foundation for improving tool performance. Second, the research on the yttrium content regulation mechanism has also achieved important results. As the yttrium content increases from 8% to 15%, the XRD pattern (Figure 3) shows that the cubic phase remains stable, and grain growth is effectively inhibited, achieving refinement of the coating structure. However, the research team also points out that although high yttrium content can improve hardness and wear resistance, it needs to be balanced with thermal conductivity, as reflected in the slightly higher thermal conductivity of 15YSZ than that of 8YSZ.

Figure 4. FESEM image of a multilayer coating (YSZ) on carbide insert: (a) 8YSZ 100000 Mag., (b) 8YSZ 25000 Mag.

Figure 3. XRD Pattern of (a) carbide cutting tool, (b) 8YSZcoating

Industrial Application Prospects

In terms of industrial application prospects, the research findings offer broad market space and significant economic value. In high-wear scenarios such as automotive manufacturing and mining drilling, experimental data show that the service life of coated tools is increased by over 50%. This means enterprises can reduce tool replacement frequency and downtime, thus significantly improving production efficiency. Meanwhile, the 85% reduction in wear rate directly translates to substantial machining cost savings, effectively controlling both tool procurement and maintenance costs. Additionally, the low friction coefficient reduces energy consumption during tool operation, aligning with the global trend of green manufacturing and yielding non-negligible environmental benefits. The research conducted by the team from the Department of Materials Engineering, University of Babylon, Iraq, not only paves a new path for tungsten carbide tool coating technology but also demonstrates the immense potential of sol-gel processes in high-temperature industrial components. Looking ahead, with further optimization of yttrium content and multi-layer structure design, the performance of tungsten carbide tools is expected to achieve new breakthroughs, bringing more surprises and transformations to the industrial processing field.

Вывод

This study not only provides a novel solution for tungsten carbide tool coating technology but also reveals the huge potential of sol-gel processes in high-temperature industrial components. In the future, optimizing yttrium content and multi-layer structure design may further break through performance limits!