What is Rotary Indexing Machining?

Definition

Rotary indexing machining, abbreviated as rotary indexing, refers to a machining method where both the tool and the workpiece rotate simultaneously to achieve cutting and indexing. By adjusting the speed ratio between them, different types of parts can be machined. It is suitable for parts with circularly distributed machining surfaces, such as gears and splines.

Mechanism

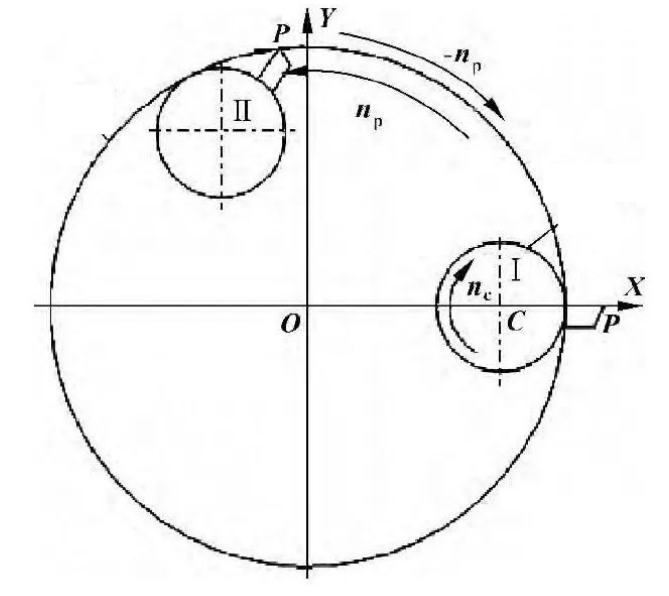

The focus of rotary indexing machining is to control the relative positions and movements between the workpiece and the tool at each instant during the machining process, making the trajectory of the contact point a straight line. This utilizes the principle of forming an involute in mathematics, hence it is also known as involute machining. Although it may sound simple, it involves complex mathematical functions. The machining motion trajectory can be viewed as the synthesis of two motions:

1.a circular motion with a speed of np revolving around the center O of the base circle;

2. a circular motion with a speed of nc rotating around its own center C. By adjusting parameters such as speed ratio, different machining paths can be achieved. Detailed mathematical calculations are not explained here.

Advantages and Disadvantages?of Rotary Indexing Machining

The major advantage of rotary indexing machining is transforming traditional intermittent machining into intermittent continuous machining, saving indexing time, significantly improving machining efficiency, and obtaining better surface accuracy. Additionally, it belongs to dry cutting, eliminating the need for cutting fluid and reducing production costs to some extent, making it an economical machining process.

However, rotary indexing machining is not a perfect technology. When machining parts with different dimensions, reprogramming is required, increasing the operational difficulty. Tool wear is also more severe than traditional machining. These drawbacks limit its practical application, and currently, it is only used in small-scale production.

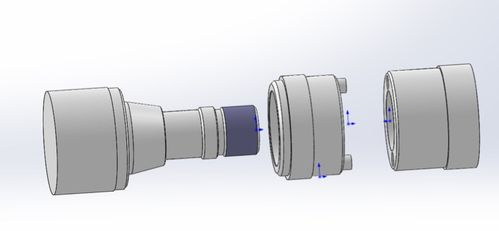

Development of Rotary Indexing Machining Equipment

Overseas

Germany and Japan were the first countries to explore the field of rotary indexing machining equipment. They have developed relatively mature technologies and put them into production.

Germany can be considered a pioneer in the development of CNC rotary indexing machines. In the early days, they developed CNC rotary indexing cutting technology based on the needs of German car manufacturers such as Mercedes-Benz, patented it globally, and developed powerful CNC involute rotary indexing machining equipment. To this day, they are still committed to the research and development of dedicated cutting machines based on rotary indexing theory. One of the distinctive technologies of Germany’s Wera is the use of patented rotary indexing technology, combining hobbing and broaching in the method called “hob-broach.” It can machine various tooth profiles, including involute and non-involute, without the need for tool retraction grooves.

Japan has also developed rotary indexing machines that can be used for processing groove-type parts, gear chamfering and deburring, and complex surfaces.

Domestic

China began researching rotary indexing machining around 2003 and has achieved some important research results. The machining range includes R-series groove types (small shafts, disc teeth, shaft teeth), M-series complex surfaces (square, hexagon, polygon, combined teeth). Chinese universities started developing rotary indexing machining technology and equipment with independent intellectual property rights in 2002, focusing on the development of rotary indexing chamfering machining centers. They successfully developed rotary indexing chamfering machining centers and completed the machining of grooves and taper chamfers on synchronizer gear sleeves.

However, due to factors such as strong specialization and operational difficulty, China’s CNC rotary indexing machines still have a significant gap, urgently requiring researchers to fill. Currently, most machine tools used by Chinese enterprises rely on imports, resulting in high costs.

Conclusion

The advantage of rotary indexing machining lies in its high efficiency, reducing the machining time from minutes to tens of seconds. Although it has not been widely popularized due to current development constraints, it is still a highly promising new technology. With the joint efforts of researchers and enterprises, the future of rotary indexing machining is expected to create a new situation in China’s machining industry.