They can be usefully used for finishing stands of high-speed wire rod mills (up to 120 m/s),precision rolando of rebars, alloy steels, and non-ferrous metals, and high-reduction passes where wear resistance is critical

Practical condition

Located in Guangdong Province, A metal production company commissioned its high-speed wire rod mill (with an annual capacity of 1.2 million tons of φ5.5~φ16mm wire rods) in December 2010 to enhance production efficiency and meet market demands.

The mill primarily consists of five key components: roughing mill, intermediate mill, pre-finishing mill, and finishing mill. The roughing mill features a single-line configuration with 5 stands (φ550×5) arranged in horizontal-horizontal-vertical-horizontal-vertical (HHVHV) pattern. The intermediate mill comprises 8 stands (φ550×2+φ450×4+φ350×2) with all-horizontal rolls. The pre-finishing mill has 8 stands (dual-line, 4 stands per line) configured as cantilever-type two-high mills (φ285×4×2) with alternating horizontal/vertical arrangement. The finishing mill contains 20 stands (dual-line, 10 stands per line) of cantilever-type two-high mills (gang-driven, φ228×5+φ170×5) in 45° top-cross configuration.

Due to humid climatic conditions, the mill encountered roll ring explosions caused by moisture-induced rusting of roll rings and taper sleeves. A technical task force was established to identify root causes and implement corrective measures to ensure stable production.

Production Process Overview

The manufacturing process flows as follows:

1.After single-pass rolling in the roughing mill, the billet undergoes head/tail cropping at #1 flying shear (with emergency scrap chopping capability), then diverges into dual lines via a distributor for intermediate rolling under micro-tension control.

2.Following intermediate rolando, the stock passes through #2 flying shear for cropping before entering pre-finishing mill, where pneumatic vertical loopers enable twist-free, tensionless rolling for precise dimensional control.

3.Pre-finished stock undergoes water cooling and #3 flying shear cropping before entering finishing mill. Emergency shutoff shears activate to prevent further stock entry during malfunctions.

4.The 45° top-cross finishing mill employs gang-driven tungsten carbide roll rings for twist-free micro-tension rolling, achieving final dimensions at speeds up to 95m/s for φ5.5~7mm products.

Root Cause Analysis of Roll Ring Failures

The cost-optimized tungsten carbide roll rings exhibited these failure mechanisms:

Ambient humidity caused rust corrosion at roll ring/taper sleeve interfaces

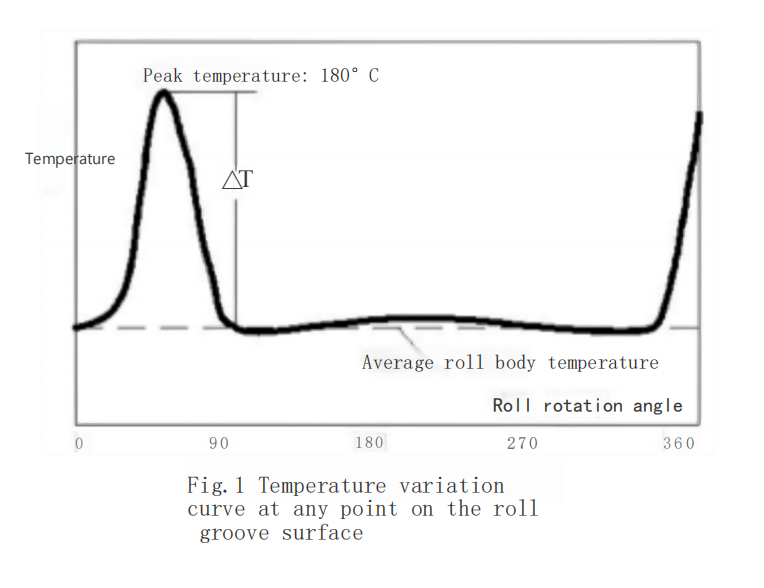

Thermal fatigue from cyclic temperature variations (Fig.1) accelerated crack propagation

Insufficient cooling exacerbated thermal stresses (increased ΔT)

Improper assembly caused taper sleeve seizure

Brittle material properties increased handling damage risks

Technical Improvements & Process Controls

Material Selection Optimization

The YGR-series roll rings were selected for their Ni/Cr-enhanced properties:

1.Superior oxidation resistance (700-1000℃)

2.Improved acid corrosion resistance (pH≤7.2)

3.Enhanced thermal crack resistance

4.Optimal hardness-toughness balance across mill stands

Cooling System Enhancements

Implemented strict water management protocols:

1.Flow rates: 18-25m3/h per stand (slot-width dependent)

2.Pressure maintenance: 3-7bar at nozzles

3.Monthly water quality testing for particulate control

Dedicated pipe alignment inspections during maintenance

Optimum Rolling Tonnage

Established safe grinding thresholds at 0.2-0.4mm crack depth:

Stands 1-4: 1,800-2,500 tons

Stands 5-8: 1,500-2,000 tons

Stands 9-10: 600-1,000 tons

Precision Assembly Standards

Mandatory surface cleaning before assembly

Prohibited impact mounting methods

Individual roll storage in partitioned containers

Strict taper sleeve inspection/rejection criteria

Conclus?o

The comprehensive improvement program addressing material selection, cooling optimization, production control, and precision maintenance successfully resolved roll ring failures, achieving sustained operational stability. This methodology provides valuable reference for similar applications.

Key Recommendations

1.Select roll ring grades considering environmental factors

2.Maintain rigorous cooling water quality standards

3.Adhere to prescribed rolling tonnage limits

4.Implement precision handling and maintenance protocols