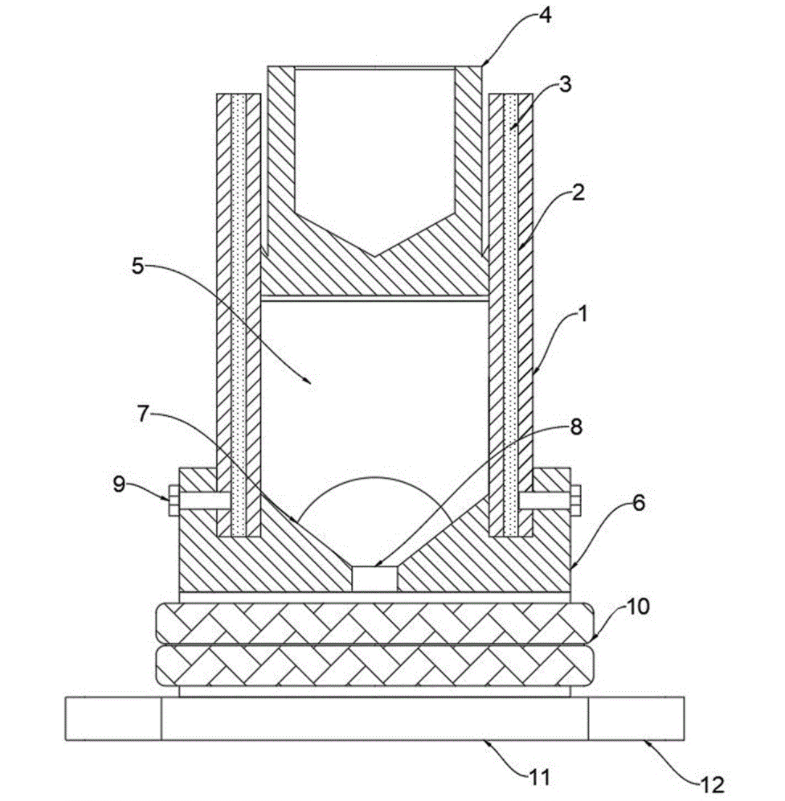

Due to the construction of the press, the working surface of the anvil is much smaller than the piston area of the hydraulic cylinder. When a set of anvils is closed under the drive of the hydraulic cylinder to form a high-pressure chamber, pressures exceeding 10GPa and temperatures of over a thousand degrees Celsius can be reached within the chamber. It endures various types of stress, including compression, tension, and shear stress. Therefore, the quality of cemented carbide anvils is particularly crucial.

Control the quality from production perspective

Reduce the carbon distribution gradient within the cemented carbide

To obtain a high-quality cemented carbide anvil, it is necessary to ensure a uniform structure of the anvil. This requirement involves achieving uniform carbon distribution within the alloy. As previously mentioned, the cemented carbide anvil is a solid product. Therefore, during the removal of the forming agent, a certain amount of carbon residue is left in different parts of the cemented carbide anvil. This leads to a carbon gradient within the anvil, which directly affects its quality. Since the carbon gradient differs from the desired structure for anvil usage, efforts should be made to minimize or even eliminate this gradient, posing significant challenges to the manufacturing process.

Currently, there are several common methods to reduce this gradient effectively:

Production Method: Adopting continuous dewaxing and sintering or intermittent dewaxing with controlled atmosphere sintering in the production process.

Process Optimization: Adjusting the dewaxing process based on the dimensions of the anvil. For anvils of different specifications, employing a low-temperature, slow-speed dewaxing method helps to remove the forming agent in a controlled manner. This approach helps to keep the carbon gradient within a narrow range for the anvil.

Select appropriate cemented carbide grades based on different purposes

The grades suitable for cemented carbide anvils include YG6, YG8, and YG12x, among others.

YG6 grade cemented carbide is composed of 94% WC (tungsten carbide) and 6% Co (cobalt), primarily using medium-sized WC and Co particles. The higher content of the hard phase WC ensures the required compressive performance of the cemented carbide anvil. However, the lower content of the binding phase Co somewhat affects the tensile strength of the anvil, leading to a tendency for cracking during the diamond synthesis process. Additionally, controlling the carbon (C) content in YG6 cemented carbide anvil poses challenges, as free carbon or eta phase may form during synthesis, affecting the anvil’s usability.

YG8 grade cemented carbide contains 92% WC and 8% Co, making it a medium-sized particle cemented carbide. It exhibits not only good compressive performance but also excellent tensile strength. It has a longer service life and is less prone to early cracking.

YG12x grade cemented carbide is a fine-particle carbide. With a certain Co content, finer WC grain size leads to significant improvements in density, hardness, compressive strength, and other comprehensive properties. This makes YG12x an ideal choice among cemented carbide materials for anvils.

Prevent damage to cemented carbide anvils during usage

Forms of damage to cemented carbide anvils

For the majority of anvils, their failure is often characterized by the presence of one or several cracks on the 46-degree inclined plane, extending from that location to the top surface, ultimately leading to fracture. Analysis has indicated that the maximum shear stress experienced by the anvil occurs along the central axis, while the highest tensile stress takes place along the symmetrical line of the 46-degree inclined plane. Therefore, under the conditions of high temperature and high pressure during synthesis, if local stress becomes excessively concentrated, small internal cracks will gradually propagate towards the surface. This is the reason why cracks typically initiate from the 46-degree inclined plane and continue to propagate until a significant portion of the anvil fractures.

Uneven temperature during the usage of cemented carbide anvils

Uneven temperatures can also lead to the phenomenon of anvil cracking. Changes in temperature can cause objects to expand or contract, giving rise to thermal stress. Alternating thermal stress is one of the factors contributing to fatigue fracture in anvils. The highest temperature of the anvil occurs at the contact point between the anvil and the conductive steel part, while the lowest temperature is at the center of the anvil’s bottom surface. The maximum temperature difference between the anvil’s top surface and bottom surface is around 500°C. The uneven temperature distribution across the anvil’s surface leads to stress concentration and, consequently, fractures. Additionally, when an electric current is applied to the anvil, its lifespan is significantly reduced due to the uneven temperature distribution.

Using a press with unstable pressure

The poor stability of the ultra-high pressure equipment in the press is also one of the reasons for accidents. For example, inconsistent pressures and strokes among the six working cylinders or sudden drops in pressure in a particular cylinder can contribute to these incidents.

Conclus?o

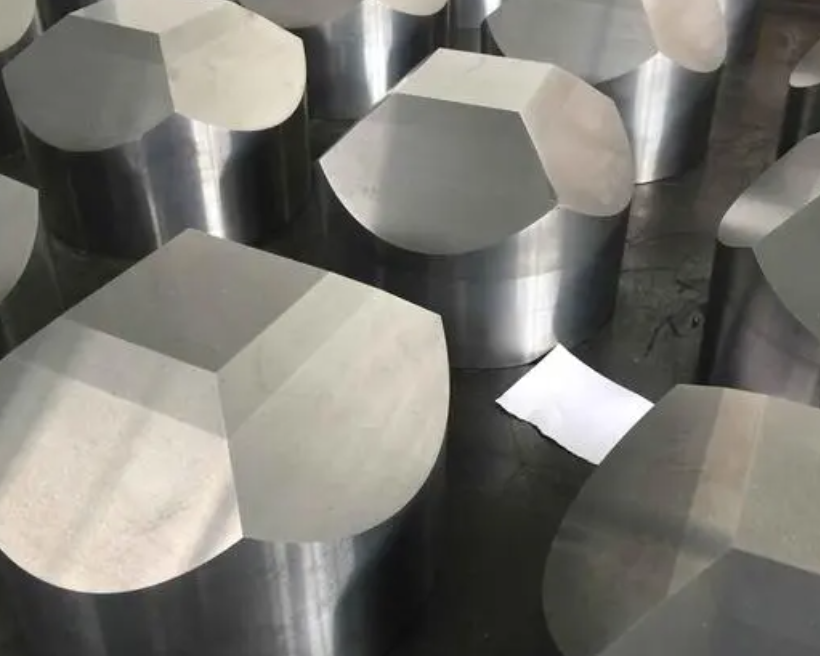

Currently, the quality of cemented carbide anvils in China has evolved from the earliest versions weighing less than 3 kg to the present-day anvils weighing around 50 kg. Large-scale six-sided anvils have become dominant in the Chinese market for superhard material synthesis chambers. Fine-grain and sub-micron fine-grain cemented carbides have also become important directions for the development of new anvil materials. Their compressive strength and flexural strength have significantly improved. With the introduction of advanced cemented carbide technology into the production process of new material anvils, the practical application of large anvils made from new materials has reached a considerably high level. The hammer consumption for diamond production has been controlled to be less than 1 kg per 10,000 carats, with the best results ranging from 0.15 to 0.3 kg per 10,000 carats.

Currently, various superhard material manufacturers pursue larger-sized presses for efficiency, which results in the gradual enlargement of cemented carbide anvils. Generally, as cemented carbide anvils become larger, the chamber size increases, and their lifespan correspondingly decreases. From this perspective, it is important to design the geometric structure of anvils based on the principle of “supporting large masses.” Simultaneously, optimal parameters should be sought between enlarging the anvil and hydraulic cylinder dimensions and their lifespans, ensuring a more reasonable balance between technical and economic considerations.