Carbide Manufacturing Process

The process involves weighing ultra-fine WC powder and Co powder, produced by special methods, according to the composition ratio, and adding small amounts of elements such as Ti, Ta, Nb, and Cr. Wet grinding is performed using φ8 cemented carbide balls with a ball-to-material ratio of 5:1. The grinding medium is anhydrous alcohol, and the grinding time ranges from 72 to 120 hours. The slurry is dried at 80 to 100°C for about 2 to 4 hours, then mixed with glue (wax) to form granules. These are pressed into various products such as 5×5×30 and A118A, and sintered under H? protection at temperatures between 1400°C and 1500°C.

Microstructure and Physical-Mechanical Properties

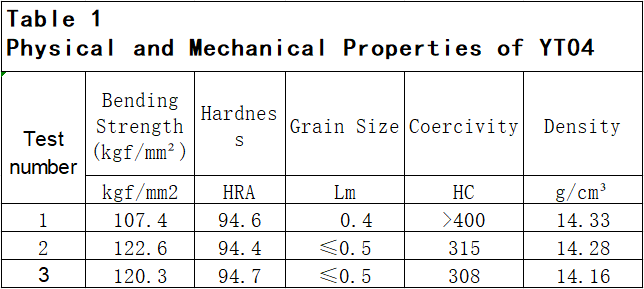

Due to the use of special raw materials and production methods different from conventional processes, and the appropriate selection of types and quantities of added elements, the YT04 carbide achieves the desired effects. Table 1 lists the performance indicators of the YT04 carbide grade from several developments, and Figure 1 shows the metallographic structure of the YT04 carbide.

From the results in Table 1 and Figure 1, the YT04 carbide has high hardness and moderate strength. The microstructure is very uniform, with grain sizes almost all less than 0.5 μm, except for a few WC grains larger than 0.5 μm. The thickness of the binder phase is also less than 0.5 μm.

Cutting Characteristics

Application Range of YT04 carbide

Due to its extremely fine WC grain size and high hardness, the YT04 carbide has very high wear resistance, red hardness, and thermal strength, along with high strength. This carbide is suitable for machining difficult materials such as ferrosilicon, vanadium-titanium cast iron, boron-added cast iron, white cast iron, high, medium, and low nickel-chromium chilled cast iron; various quenched carbide steels, tool steels, magnetic steels, high manganese steels, ultra-high strength steels, high-speed steels; tungsten-based, molybdenum-based, titanium-based non-ferrous carbides; granite, marble, glass, cast stone, high-cobalt cemented carbide, steel-bonded cemented carbide, and some ceramic materials and engineering plastics for precision turning, milling, planing, and cutting. It can also be used for semi-finishing, with a durability 1 to 10 times higher than traditional YT, YG, and YM grade cemented carbides. The surface finish of the machined workpiece can reach up to ▽8. It shows particularly satisfactory results when used for low-speed cutting to replace high-speed steel tools.

Usage Conditions of YT04

According to relevant literature, the YT04 carbide should be used with the following parameters:

(1) Main cutting edge angle (K,) ≤ 45°.

(2) Rake angle (Y.) = 0 to -8°, cutting edge inclination angle (λ) = -5 to -9°.

(3) Clearance angle (a.) and tool nose radius (Ye). Since the YT04 carbide is only suitable for finishing and semi-finishing, a larger clearance angle should be chosen to reduce friction between the flank face and the workpiece surface, typically around 10°. The tool nose radius should be 1 to 2 mm.

(4) Cutting speed (V). The cutting speed should be determined based on specific conditions. For workpieces with HRC60 and above, a cutting speed of 10 m/min is ideal, and should not exceed 20 m/min to avoid tool tip reddening and burning. For materials around HRC45, the cutting speed can be increased to about 50 m/min, but should not exceed 100 m/min to fully utilize the tool’s excellent performance. For materials like 35CrMoA (HB≈229), the cutting speed can even be as high as 200 m/min or more.

(5) Depth of cut (αp). This depends on the surface quality requirements of the workpiece. For a finish of 76 or above, the cutting depth can be set at 0.07 to 0.12 mm. If the precision requirements are not strict, it can be set at 0.2 to 0.4 mm.

(6) Feed rate (f). YT04 is generally used for finishing, with a feed rate typically of 0.2 to 0.3 mm. For semi-finishing, the feed rate can be increased to 0.4 to 0.5 mm. It should be noted that if machining high-hardness materials around HRC65, too large a feed rate can cause chipping.

Cutting Examples

Here are some examples of YT04 carbide in practical use:

- Material: Cast stone, workpiece size: Φ160×1500, external turning, tool geometry parameters: K,=45°, Y.=12°, α=6°, λ=-6°; cutting parameters: V=6 m/min, f=0.1 mm/r, ap=1.00 mm.

- Material: Quenched bearing steel, HRC62, workpiece: Φ30×50 mm, external turning; tool geometry parameters: K=40°, Y.=15°, α.=10°, Re=0.5 mm. Cutting parameters: V=61.8 m/min, f=0.14 mm/r, αp=0.4 mm. Test results: After machining 11 pieces per cutting edge, the cutting path reached 2472 m, with basically no wear on the cutting edge, and a workpiece surface finish of 76.

Usage Instructions

1.Strictly follow the provided tool geometry parameters and cutting conditions.

2.YT04 carbide is not suitable for intermittent cutting.

3.YT04 carbide can be sharpened with green silicon carbide wheels. Using diamond oil stones for edge honing can further improve performance.

Conclus?o

Overall, the YT04 carbide, with its extremely fine grain size and excellent physical-mechanical properties, performs exceptionally well in machining difficult-to-process materials and is suitable for various precision machining applications.