Characteristics and Grinding Difficulties of Carbide Materials

Carbide materials (such as YG series and YT series), sintered from tungsten carbide (WC) and cobalt (Co), possess extremely high hardness and wear resistance. The main challenges during grinding are as follows:

High hardness: Ordinary alumina grinding wheels cannot achieve effective grinding.

Susceptibility to chipping: Improper grinding may cause micro-chipping at the cutting edge, affecting the tool life.

Thermal sensitivity: High temperatures may soften the cobalt bonding phase, impairing the tool performance.

Key Factors for Grinding Wheel Selection

Grinding Wheel Abrasives

The following abrasives are commonly used for grinding carbide materials:

Diamond:

Most suitable for grinding carbide materials due to its highest hardness (Mohs hardness 10) and excellent wear resistance. Ideal for precision and super-precision grinding, but with higher costs.

Cubic Boron Nitride (CBN):

Second only to diamond in hardness, with better high-temperature resistance, making it suitable for high-speed grinding.Suited for high-precision machining, but relatively expensive.

Recommendation:

Prioritize diamond grinding wheels for carbide materials. If budget is limited, CBN grinding wheels can be considered.

Bonding Agents

Bonding agents affect the strength and grinding performance of grinding wheels:

Resin Bond (B):

Good elasticity, suitable for precision grinding, less likely to burn the workpiece, but with poor wear resistance.

Metal Bond (M):

High strength, long service life, suitable for high-efficiency grinding, but with poor self-sharpening property.

Ceramic Bond (V):

High-temperature resistant, suitable for high-speed grinding, but relatively brittle.

Recommendations:

1.For precision grinding: Resin-bonded diamond grinding wheels.

2.For high-efficiency grinding: Metal-bonded diamond grinding wheels.

Grinding Wheel Hardness

The hardness of a grinding wheel refers to the difficulty with which abrasive grains fall off:

Soft grinding wheels (Grade G~K): Good self-sharpening property, suitable for precision grinding, and reduce the risk of burning.

Hard grinding wheels (Grade L~P): Wear-resistant, suitable for rough grinding, but prone to heat generation.

Recommendations:

For precision grinding of carbide materials: Soft grinding wheels (e.g., Grade J).

For rough grinding: Medium-hardness grinding wheels (e.g., Grade L).

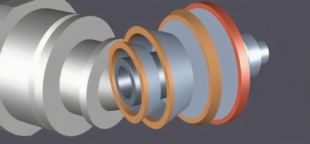

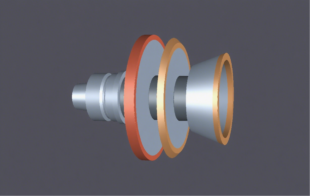

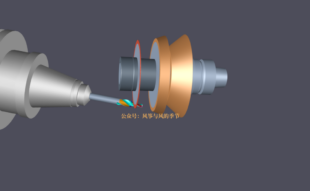

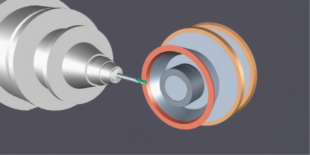

Grinding Wheel Shapes

Depending on the grinding positions and tool types, commonly used grinding wheel shapes include:

Flat grinding wheel (1A1):

Suitable for grinding the tool tip angle, outer diameter, and back surface, and also often used for grooving.

Dish-shaped grinding wheel (12V9, etc.):

Applicable to grinding chip pockets, spiral grooves, peripheral teeth, and end teeth.

Bowl-shaped grinding wheel (11V9, 12A2):

Frequently used for precision grinding of peripheral teeth, end teeth, and complex contours.

Cup-shaped grinding wheel (6):

Suitable for sharpening fine-tooth tools to avoid damaging adjacent teeth.

Grinding Wheel Grit Size

The selection of grinding wheel grit size depends on the grinding stage (rough grinding or precision grinding) and surface roughness requirements:

Rough grinding: Coarser grit sizes are usually used, such as D46, D54, or above D64 (corresponding to approximately 230-270 mesh).

Precision grinding: Finer grit sizes are recommended, such as below D20, or even up to 1000 mesh, to achieve higher surface finish.

Special requirements: For high-precision grinding, ultra-fine grit diamond grinding wheels (such as grit below D8, or below 2000 mesh) can be selected.

Common Grinding Wheels

Resin-bonded Diamond Grinding Wheel

Tool types: Precision tools such as carbide turning tools, drills, reamers, etc.

Grinding positions:

Edge precision grinding: Final finishing of sharp cutting edges (e.g., rake angle, relief angle, land).

Complex profiles: Contour grinding of formed tools (e.g., ball-nose tools, gear cutting tools).

Features:

The resin bond has good elasticity and low grinding vibration, suitable for high surface quality requirements.

Diamond abrasive grains have high hardness and strong wear resistance, suitable for high-hardness materials such as carbides (WC-Co).

High-power Grooving Grinding Wheel

Tool types: Carbide tools requiring grooving or rough machining, such as end mills, drills, saw blades, etc.

Rough machining of grooves: Rapid forming of chip pockets, spiral grooves, and straight grooves of tools.

Deep groove/large allowance removal: Efficient material removal, usually used as a rough grinding process.

Features:

High bond strength (metal or ceramic bond), with a more robust wheel structure.

Thick abrasive layer and large chip filling space, suitable for working conditions with large cutting forces.

| Comparison Items | Resin-bonded Diamond Grinding Wheel | High-power Grooving Grinding Wheel |

| Bond Type | Resin (good elasticity, vibration reduction) | Resin/Metal/Ceramic (high strength) |

| Main Applications | Precision grinding of cutting edges, formed surfaces | Rough grooving, large allowance removal |

| Surface Quality | Ra below 0.2μm | Relatively rough (requires subsequent finishing) |

| Grinding Force | Light cutting, avoiding burning | Heavy cutting, high feed rate |

| Grinding Wheel Life | Longer (resin has good self-sharpening property) | Shorter (fast wear in rough machining) |

Common Problems and Solutions

Problem 1: Rapid wear of grinding wheel Possible cause: Inappropriate bonding agent or overly fine grit size. Solution: Switch to metal bonding agent or use a coarser grit size.

Problem 2: Edge chipping Possible cause: Grinding wheel is too hard or feed rate is too high. Solution: Select a softer grinding wheel and reduce the feed rate.

Problem 3: Grinding burn Possible cause: Insufficient cooling or poor self-sharpening property of the grinding wheel. Solution: Enhance cooling and switch to resin-bonded grinding wheels.

Sumário

When selecting grinding wheels for carbide materials, factors such as abrasive (diamond/CBN), grit size, bonding agent, and hardness should be comprehensively considered:

Rough grinding: Diamond grinding wheel (80#~150#) + metal bonding agent + medium hardness.

Precision grinding: Diamond grinding wheel (400#~1200#) + resin bonding agent + soft hardness.

Optimization parameters: Control linear speed and feed rate, and ensure sufficient cooling.