Inspection of flange fasteners

1. Junta: durante a instala??o, certifique-se de que a junta é nova, limpa e seca, e verifique se a junta está com defeito ou danificada; a junta antiga n?o pode ser reutilizada; antes da instala??o, confirme se o tamanho e grau da junta usada s?o consistentes com a identifica??o do flange.

2.Flange: check whether the flange face is damaged before installation, If scratches, nicks, mud, corrosion and burrs, dents and scratches passing through the water line of flange sealing surface in radial direction, and the depth of scratches is more than 0.2mm, and the covering surface is more than half of the width of gasket sealing surface, the flange must be replaced or the sealing surface must be reprocessed and repaired; the position of nut support surface on the back of flange should be parallel and smooth; check whether the flange is aligned, and the inspection method shall be in accordance with 6.2 of sh3501-2011 Pipeline installation requirements.

3.Bolt and nut: check whether the bolt and nut are used correctly according to the design requirements of equipment and pipeline; the thread and contact surface shall be free of dirt, rust, double skin, scratch, burr, debris and other external substances that affect the torque in the tightening process; it is not allowed to repair the bolt by welding or machining; at least two threads shall be exposed outside the nut after the flange is installed and tightened;

Bolts and nuts must be lubricated before use, so as to have low friction coefficient when tightening bolts and improve the anti sliding wire and anti-corrosion performance of bolts and nuts; stud thread, nut thread and contact surface must be degreased and dried before using lubricating oil; unified lubrication method shall be properly used for bolt thread, nut thread, nut bearing surface, washer and nut supporting surface on flange Lubricating oil; use high temperature anti seizing agent as required.

Bolt tightening method

No torque box spanner or hammer spanner: suitable for fastening flange of general equipment and pipeline, selected according to bolt size and flange pressure grade. The tightening requirements are as follows:

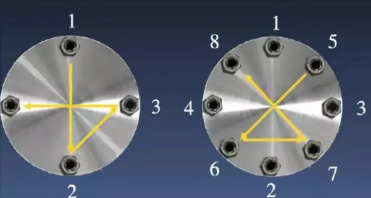

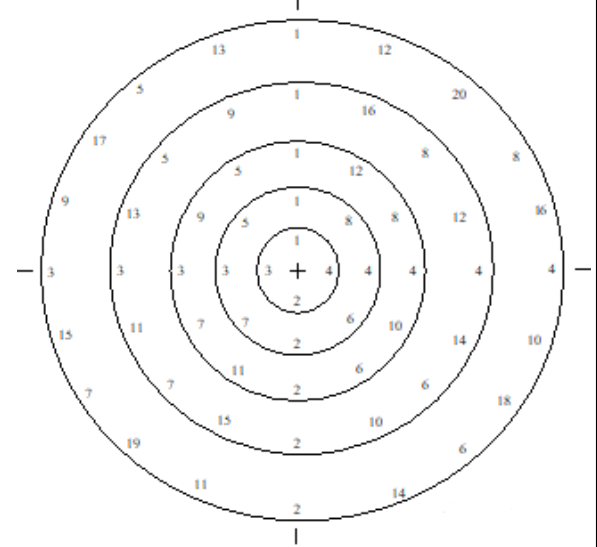

1. The maintenance unit formulates the fastening scheme, fastens the flange symmetrically, and numbers the fastening sequence. Refer to Fig. 1 and Fig. 2 for numbering.

2. Position the gasket with 4 bolts at the positions of 1, 2, 3 and 4 to ensure that the center of the spiral wound gasket is within the flange edge.

3. Tighten the positioning bolt by hand, then insert other stud bolts and balance the load by hand, so as to ensure that at least 2 threads are exposed at each end of the nut.

4. According to the on-site equipment and flange, the tightening times (at least 3 times) and the hammering load (strength) of each tightening should be reasonably determined according to the calculation of tightening one circle. The tightening hammering load (strength) should be tightened from small to large in turn (such as 50%, 80%, 100% increment). The load should not be too fast or too large to prevent gasket seal failure.

5. Tightening sequence of no torque box spanner or hammer spanner each time:

Tighten the two radially opposite bolts to the given hammering load (strength) of the bolts;

Fasten another pair of bolts about 90 degrees away from the previous two bolts along the circumference;

Continue tightening until all the remaining bolts are tightened to a given hammer load.

Finally, according to 100% hammering load (force), all bolts shall be tightened clockwise or counterclockwise.

Torque wrench: suitable for high temperature, high pressure, flammable and explosive equipment and pipe flange.

The tightening requirements are as follows:

1. The maintenance unit needs to formulate the fastening scheme, formulate the appropriate torque, and carry out the design review according to the bolt strength, the initial sealing pressure of the gasket, the working sealing pressure, the medium pressure and other parameters, so as to prevent the bolt from breaking and the gasket from losing its elasticity due to the excessive pressing force, resulting in the seal failure.

2. Fasten the flange symmetrically and number the tightening sequence. Refer to figure 1 and Figure 2 for numbering.

3. Position the gasket with 4 bolts at the positions of 1, 2, 3 and 4 to ensure that the center of the spiral wound gasket is within the flange edge.

4. Tighten the positioning bolt by hand, then insert other stud bolts and balance the load by hand, so as to ensure that at least 2 threads are exposed at each end of the nut.

5. According to the on-site equipment and flange, the tightening times (at least 3 times) and each tightening torque should be reasonably determined according to the calculation of tightening one circle. The tightening torque should be tightened from small to large in turn (such as 50%, 80%, 100% increment). The load should not be too fast or too large to prevent the gasket sealing failure.

6. Tightening sequence of torque wrench each time:

Tighten the two radially opposite bolts to the given bolt torque;

Fasten another pair of bolts about 90 degrees away from the previous two bolts along the circumference;

Continue tightening until all the remaining bolts are tightened to the specified torque.

7. Finally, tighten all bolts clockwise or counterclockwise according to 100% torque value.

8. Record the torque value for reference in future maintenance.

Bolt stretcher: suitable for high temperature, high pressure, flammable and explosive equipment and pipe flange.

The tightening requirements are as follows:

1. The maintenance unit formulates the fastening scheme, formulates the appropriate stretching force, and carries out the design review according to the bolt strength, the initial sealing specific pressure of the gasket, the working sealing specific pressure, the medium pressure and other parameters, so as to prevent the bolt from breaking and the gasket from losing its elasticity due to the excessive pressing force, resulting in the seal failure.

2. When the bolt stretcher single (step-by-step) stretches and fastens the bolt, it should follow the principle of bolt tightening uniformity and refer to the tightening sequence of torque wrench.

3. In the process of bolt stretching and fastening, the number of times of stretching and fastening should be reasonably determined. The pressure should be increased from small to large in turn (such as 50%, 80%, 100%), and evenly. Every time a certain pressure is increased, the pressure should be stabilized and then increased, so as to avoid excessive impact tension and affect the bolt pre tightening effect.

4. Record the pressurization value for reference in future maintenance.