The direction of chip flow and the chip flow angle φλ

The direction of chip flow has a significant impact on chip curling and breaking, and the angle between the flow direction and the main cutting edge plane is called the chip flow angle φλ, as shown in Figure 1. In orthogonal free cutting, chips flow out in the vertical direction to the cutting edge, and the chip flow angle φλ is approximately 0. In oblique free cutting (such as with inclined wide-edge planing tools), the chip flow angle is approximately equal to the rake angle (φλ = λse). However, for general cutting, it is influenced not only by the primary cutting edge but also by the secondary cutting edge. In summary, the principle is that chips should flow out in the direction that minimizes energy consumption. If the direction of the chip breaker groove does not align with the chip flow direction, it can affect its chip-breaking effectiveness.

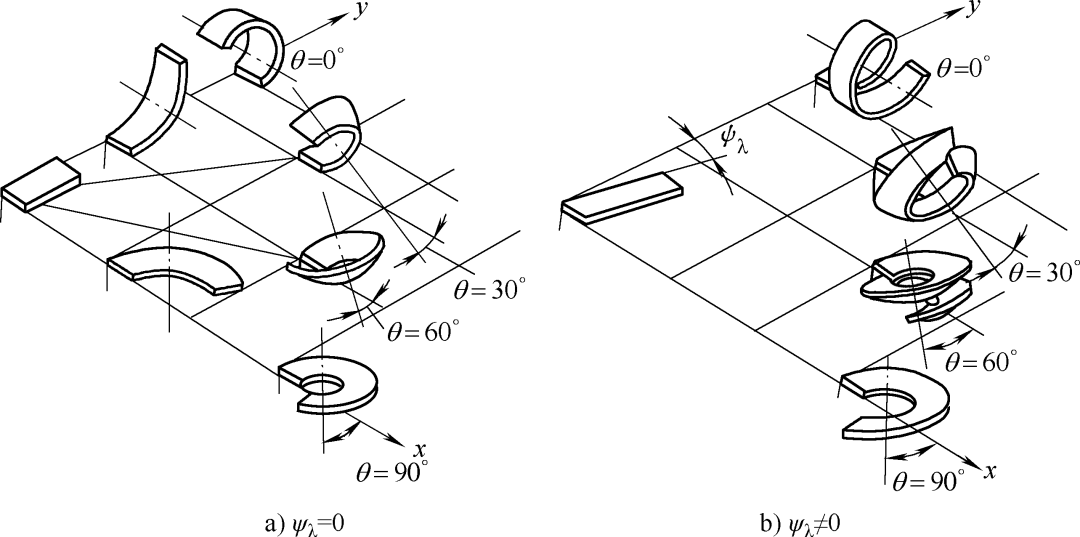

Figure 1 The effect of the chip flow angle (φλ) on chip curling

Chip curling

During the chip flow process, chips curl, and the direction and curling of the chips determine their shape. When chips only curl upward along the thickness direction of the chip, the curling axis of the chip is parallel to the chip’s bottom surface, and the angle between them is θ = 0°. Different chip shapes are formed with different chip flow angles φλ.

As shown in Figure 1, when φλ = 0°, and the chips do not have lateral flow, it results in flat spiral chips (coil-like chips). When φλ ≠ 0°, the chips curl upward and also move along their curling axis, creating a helical motion of the chips. When φλ is relatively large, if the distance the chip moves while making one revolution is greater than or equal to the nominal cutting layer width, it forms tubular spiral chips. If φλ is relatively small, and the chip moves a smaller distance along the curling axis, it is more likely to form conical spiral chips (tower-shaped chips).

When the chips only have lateral (sideways) curling and no upward curling, the curling axis of the chips is perpendicular to the chip’s bottom surface (θ = 90°), forming washer-like ring-shaped spiral chips.

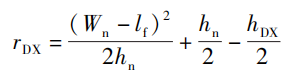

When the chips curl both upward and sideways, and the chip flow angle φλ is not zero, it can create ring-shaped or conical spiral chips, depending on the values of various parameters. The curvature radius rDX of the chips curling upward is related to the parameters of the chip breaker groove. Taking a straight-line circular arc chip breaker groove as an example, when the chip’s bottom surface contacts the shoulder of the chip breaker groove, as shown in Figure 2. The average curvature radius rDX at which the chips curl within the chip breaker groove can be calculated based on geometric relationships:

In the formula,

Wn – Width of the chip breaker groove (mm);

hn – Depth of the chip breaker groove (mm);

hDX – Thickness of the chip (mm);

lf – Length of chip in contact with the previous surface, when cutting steel, lf ≈ hDX (mm).

Figure 2 The influence of the chip groove on chip curling

Chip Groove Shapes and Parameters

Chip Groove Shape

The chip breaker groove of a welding lathe tool is ground when sharpening the tool, while for indexable lathe tools, it is directly pressed and formed during the production of the blade.

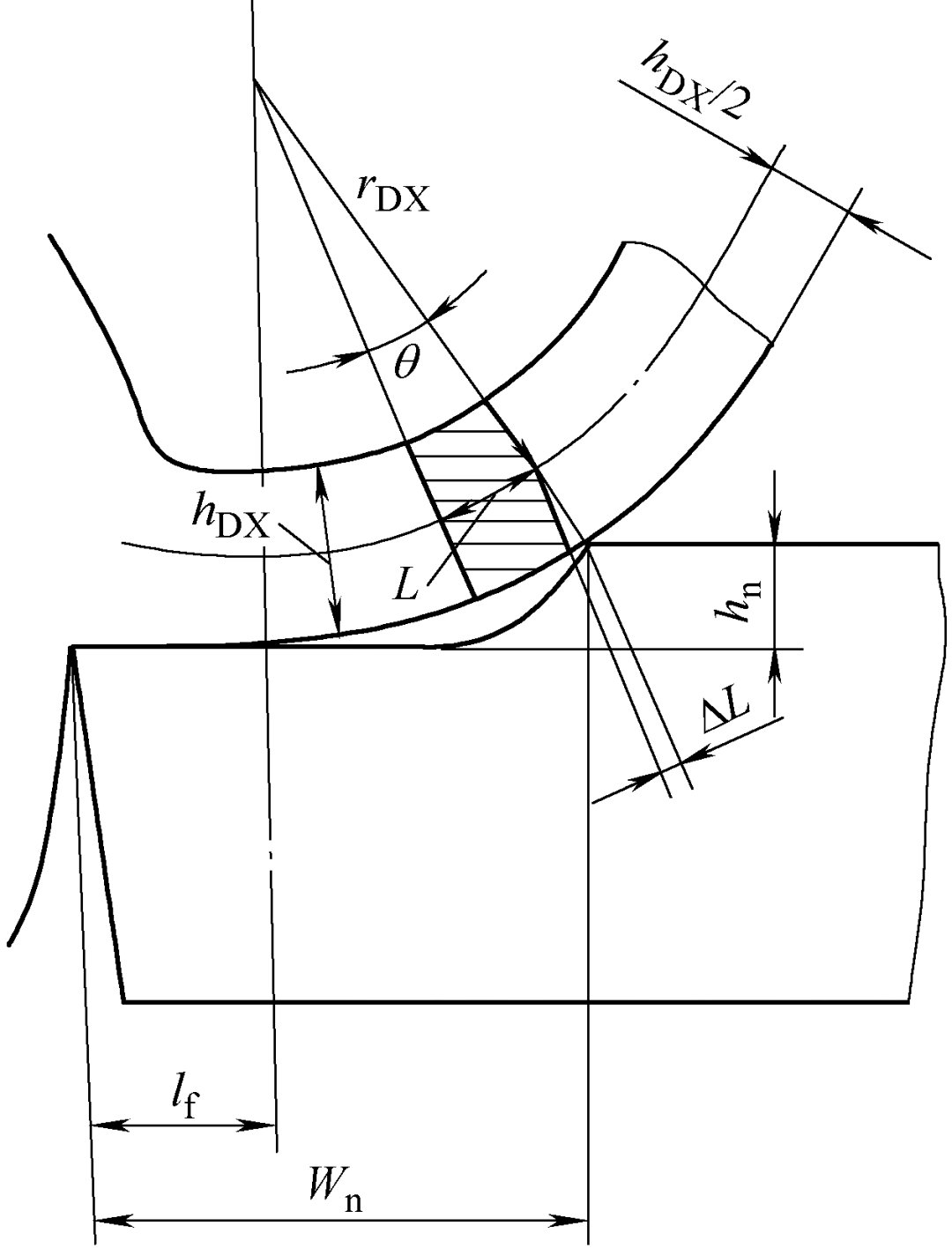

Classification of Chip Groove Shapes Based on the Section

Linear-circular chip breaker groove: This type of cross-section consists of both straight and general arcs. The front part of the lathe tool is formed by a plane section close to the cutting edge, and the basic parameters of the chip breaker groove are as follows: width Wn = 10.7)Wn, wedge angle βo ≤ 40, negative rake width bn ≤ fo. Rn and Wn are the main factors affecting chip formation, where the size of Rn directly influences the curvature radius of the chip.

Figure 3 – Basic Section of Chip Groove

Polygonal chip breaker groove: It is formed by the intersection of two straight sections. The groove bottom angle θ replaces the role of the above-mentioned arc radius Rn. When a small value is chosen, the chip curvature radius is small. If θ is too small, it can cause the chip to block in the groove, leading to chip packing. If θ is too large, it can increase the chip curvature radius and make it less likely to break. The groove angle is generally recommended to be between 110° and 120°.

Full arc-shaped chip breaker groove: Under the same conditions of front angle and groove width, a full arc-shaped chip breaker groove has higher cutting edge strength. Therefore, it is suitable for a larger front angle and heavy-duty lathe tools. The following approximate relationship exists between the groove width Wn, arc radius Rn, and front angle γo:

![]()

Classification According to Chip Groove Inclination Angle

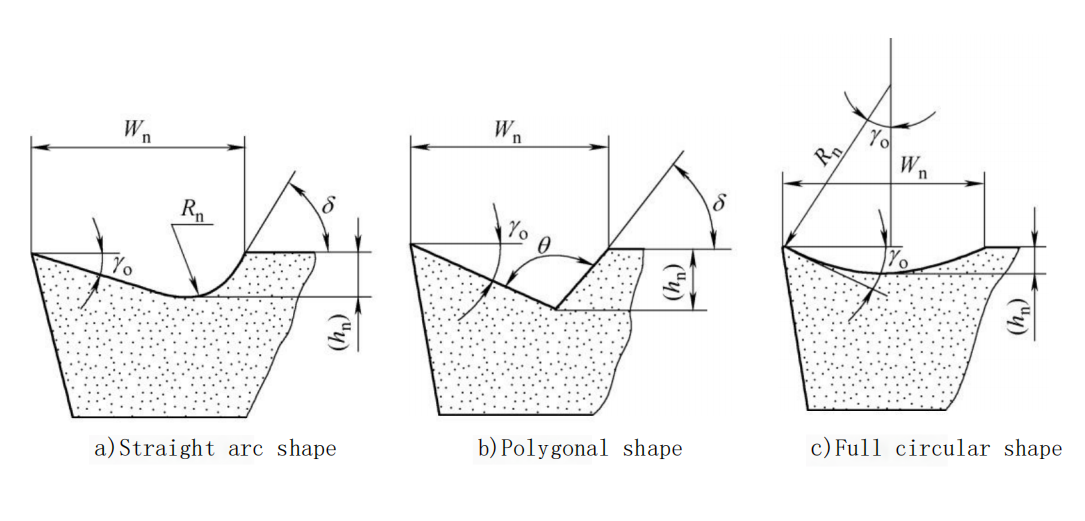

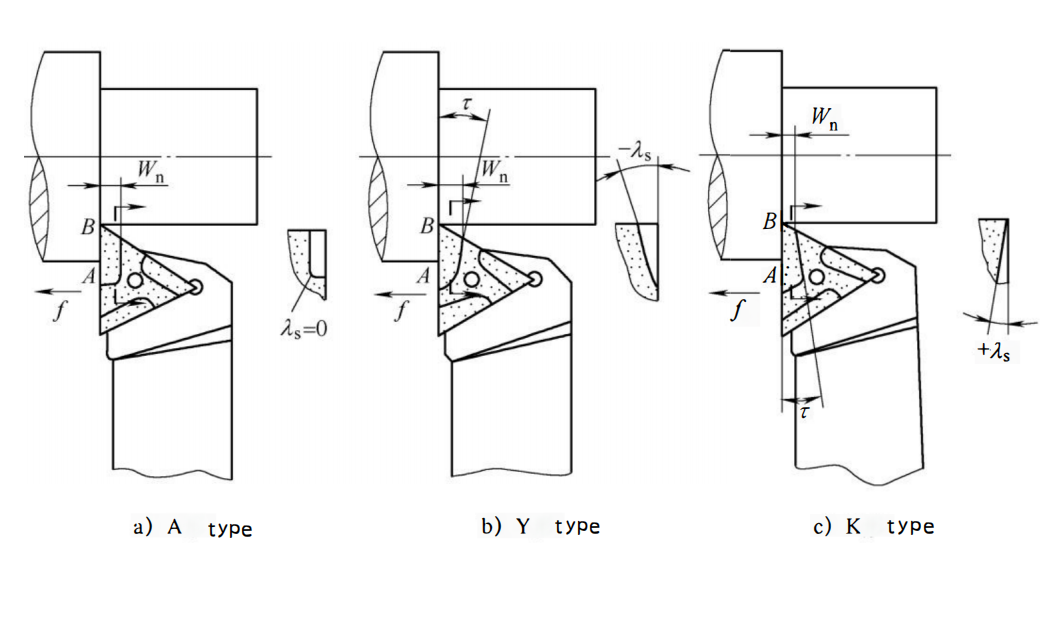

The inclination angle of the chip breaker groove shape is the angle at which the chip breaker groove is inclined relative to the main cutting edge. There are three forms, as shown in Figure 4.

Figure 4 – Common Chip Groove Inclination Angles

A-shape: This groove shape features an open semi-groove with equal width and depth in the front and rear, known as parallel-style. This groove shape can achieve good chip-breaking effects over a wide range of feed variations. However, for tool inserts with a certain groove width, their chip-breaking range is relatively narrow, and the groove width should be determined based on the feed rate.

Y-shape: Its characteristic is an open semi-groove with a wider front and narrower rear, also known as outer inclined style. In this groove shape, point A has a high cutting speed, a narrow groove width, and shallow groove depth. Chips tend to curl at this point, with a small curling radius. At point B, the chip curling is slow, the groove is deep, and the groove bottom forms a negative rake angle, making it easier for the chips to contact the workpiece surface and form arc-shaped chips. This groove shape is suitable for moderate back feed rates (ap) where chip breaking is stable and reliable. However, when ap is large, the significant difference in curling radius between points A and B can lead to chip clogging.

K-shape: This groove shape is characterized by a narrow front and wider rear open semi-groove, also known as inner inclined style. Unlike the Y-shape, point B in this groove has a narrower width and smaller depth, and the groove bottom has a positive rake angle, causing chips to easily depart from the workpiece and form tubular or ring-shaped spiral chips. Its chip-breaking range is relatively narrow and is mainly suitable for situations with low cutting volumes, finishing, semi-finishing, and guiding chip flow out of holes during hole machining.

The choice of chip groove parameters

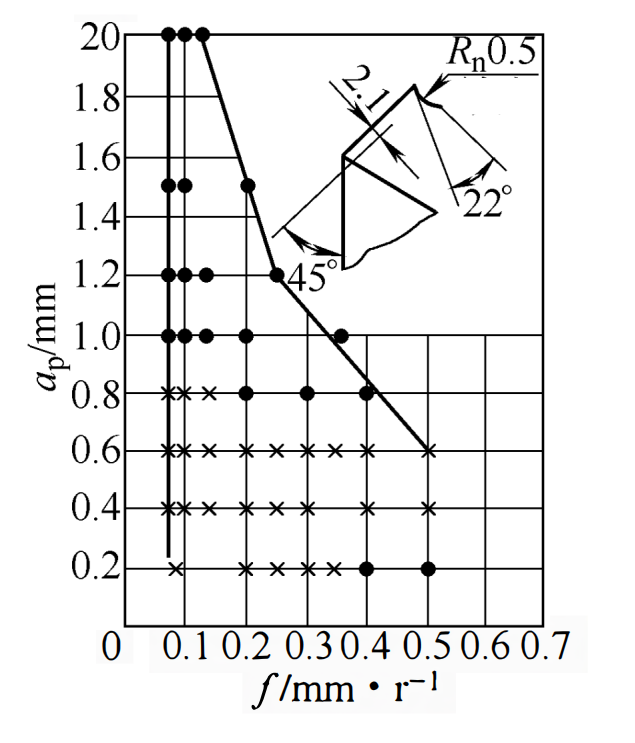

(1)When cutting medium carbon steel with moderate back feed rates and feed rates (ap = 10.6mm/r) using cemented carbide turning tools, to achieve a C-shaped chip formation, it is recommended to use a straight circular arc-shaped chip breaker groove.

For small back feed rates (ap < 1mm), the recommended chip breaker groove mentioned above may not easily break the chips. Due to the width of the chip breaker groove, the chips, under the action of the tool tip arc and secondary cutting edge, may divert towards the primary cutting edge near the tool tip without passing through the groove bottom, thus not achieving additional curling deformation. As shown in Figure 5, you can use a D-shaped chip breaker groove, ground at a 45° incline, or choose a straight circular arc-shaped A-shaped chip breaker groove. When f = 0.1mm/r, you can take Wn = 3f, hn = f, Rn = f/2.

For large back feed rates and feed rates (ap > 10mm, f = 0.6~1.2mm/r), due to the wide and thick chips, forming a C-shaped chip can easily damage the cutting edge and cause splattering of chips, which can be dangerous. Typically, a full circular arc-shaped chip breaker groove with an increased radius Rn and reduced groove depth is used.

Fig.5 45-degree angled groove with small depth of cut and its chip range

Due to the significant deformation of low carbon steel chips, the chip thickness hDX is thicker than that of medium carbon steel under the same conditions, making it easier to break chips. Cutting practice has shown that, using the same chip breaker groove parameters, the chip range for low carbon steel is wider than that of medium carbon steel. Therefore, when cutting low carbon steel, the same chip breaker groove parameters as those for cutting medium carbon steel can be used.

(2)When cutting alloy steel such as 18CrMnTi, 38CrMoAl, 38CrSi, etc., it is generally recommended to use an external oblique chip breaker groove. The groove width Wn and arc radius Rn should be appropriately reduced to facilitate chip deformation due to the increased strength and toughness of alloy steel, making chip breaking more effective.

In metal cutting, there are often materials that are particularly difficult to chip, such as high-temperature alloys, high-strength steel, wear-resistant steel, stainless steel, and non-ferrous metals like pure copper, oxygen-free copper, and pure iron.

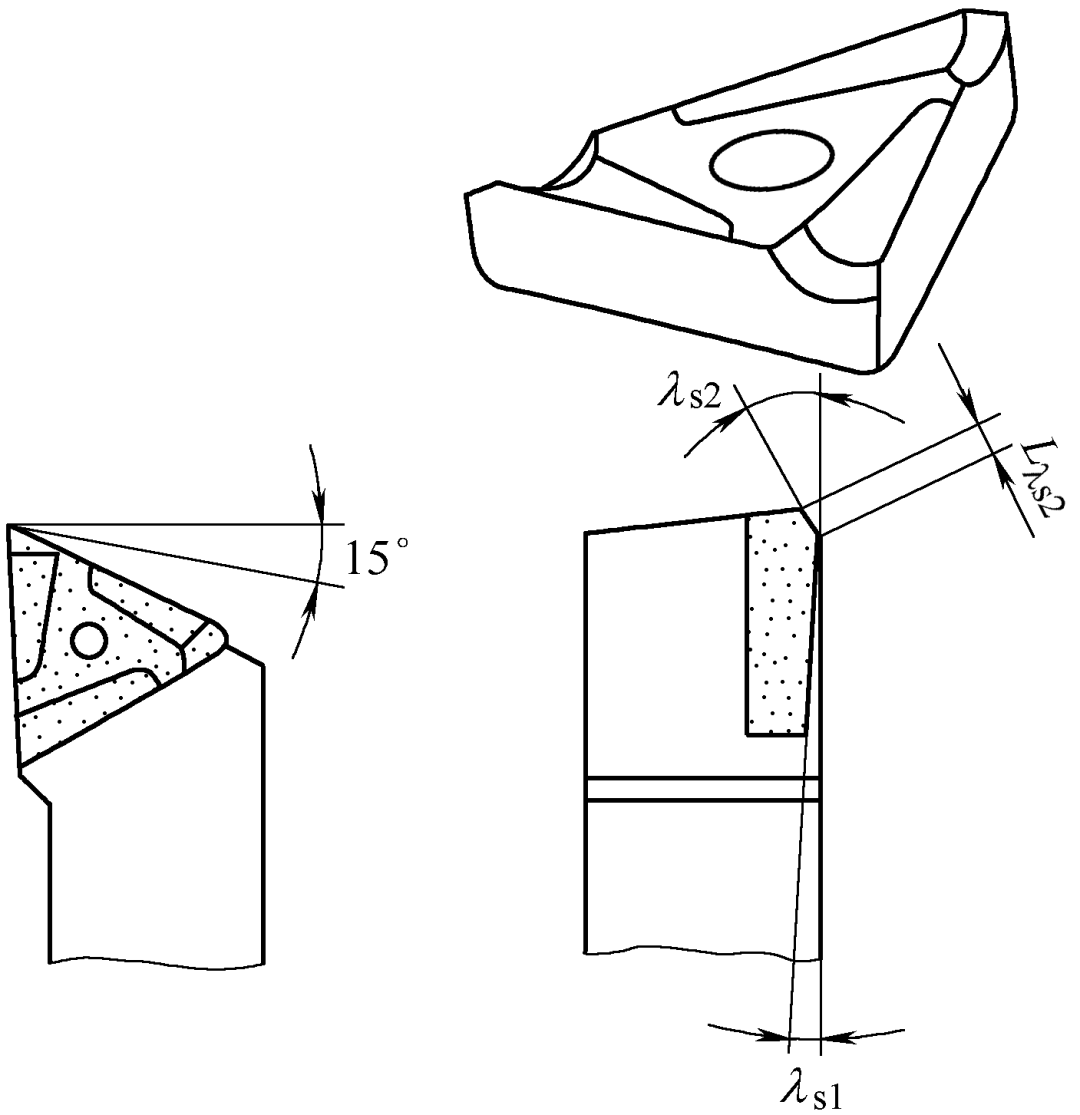

As shown in Figure 6, a double-edge chamfer angle can be used in combination with a typical external oblique chip breaker groove. The groove width Wn is typically set between 3.5 to 5mm, the external oblique angle τ is between 6° to 8°, the first edge chamfer angle λs1 is -3°, the second edge chamfer angle λs2 is between -20° to -25°, and the length Lλs2 is ap/3. The optimal cutting parameters are: ap=40.35mm/r, and vc=80~100m/min. This tool has excellent tip strength, a large chip curling radius, and typically produces conical spiral chips or short tube-like spiral chips. However, it generates 20% to 30% higher radial forces compared to single-edge chamfer angle tools and should not be used when the rigidity of the machining system is poor.

Figure 6 double-edged angled cutting edge