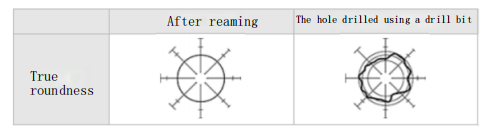

Reamers are employed on workpieces with pre-drilled (or reamed) holes to enhance the machining accuracy and reduce surface roughness. They are specialized tools for finishing and semi-finishing hole processing, with typically small machining allowances.

Unlike a single-blade cut in precision boring, reamers have 4-8 cutting edges, resulting in higher efficiency and precision. The presence of cutting edges in reamers contributes to better surface roughness.

Equipped with one or more teeth, reamers are used for reaming holes in workpieces that have been previously drilled (or enlarged). Their primary purpose is to improve the machining accuracy of holes and reduce surface roughness. These tools are suitable for precision and semi-precision hole processing, typically involving minimal machining allowances.

Due to the existence of a dull rounded cutting edge in reamers and a finishing edge, coupled with a back surface with a 0.03 to 0.05mm cutting edge, they exert significant squeezing force. As a result, the reaming process involves a combination of cutting and extrusion.

Reamers have a maximum diameter size of 30mm and a minimum diameter size of 2mm. The precision levels for reamers include D4, H7, H8, H9, among others. Diameters are commonly available in sizes such as 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 4.5mm, and so on.

Types of reamer

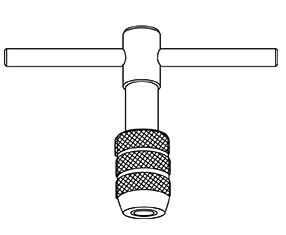

Manual reamer

A manual reamer is used in conjunction with a tap wrench or a tap handle. However, it can also serve as a machine reamer when employed for final precision machining. When mounted on machinery, it is advisable to conduct the machining at low speeds.

?Taper reamer

This type of reamer is designed for precision machining of holes with the same taper for locating pins. Standard products with a 1/50 taper are equipped with a straight blade.

![]()

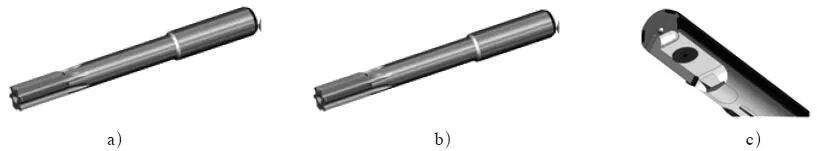

Machine reamer

This is a reamer widely used for precision hole machining on machine tools. It comes in various sizes, with a cutting angle of approximately 45 degrees.

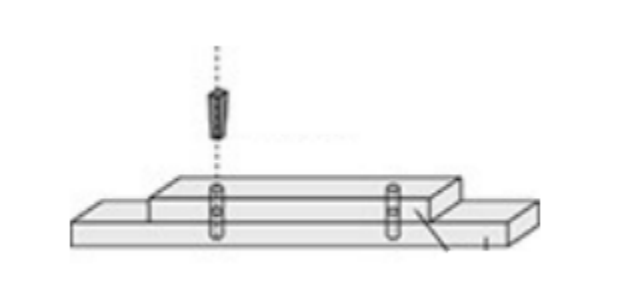

?Bridge reamers

This is a correction-type precision reamer, suitable for correcting misaligned holes for dowels or pins, or for hole?enlargement.

![]()

Single-flute reamer

Processing holes can achieve higher geometric accuracy and lower surface roughness values. When machining with a single-blade reamer, it can guide itself using the pre-machined hole, increasing the rigidity of the tool. This allows for obtaining higher geometric accuracy in a single operation, ensuring the roundness and cylindricity of the hole. The process is straightforward and easy to master.

Spiral-fluted reamer

The cutting action is light, rapid, smooth, with excellent chip evacuation, resulting in extended tool life and high-quality hole reaming. This type of reamer is commonly used for reaming deep holes or holes with interrupted surfaces (such as those with axial grooves). Spiral fluted reamers come in both right-hand and left-hand varieties.

Right-hand spiral:?Chips are expelled towards the shank direction, making it suitable for blind-hole machining. However, during reaming, axial and feed direction forces are the same, which may lead to automatic feeding, affecting machining quality. It may also cause the reamer to disengage from the machine spindle and get stuck in the workpiece. Therefore, it is advisable to use a small cutting amount.

Left-hand spiral:?Chips are directed along the feed direction, making it suitable for through-hole reaming. Axial forces press against the machine spindle, providing a more secure reamer clamping.

Adjustable reamer

As shown in Figure (c), the adjustable reamer’s blade diameter can be finely adjusted multiple times, allowing for reuse and significantly reducing reamer wear and processing costs.

Selection of cutting angles of reamers

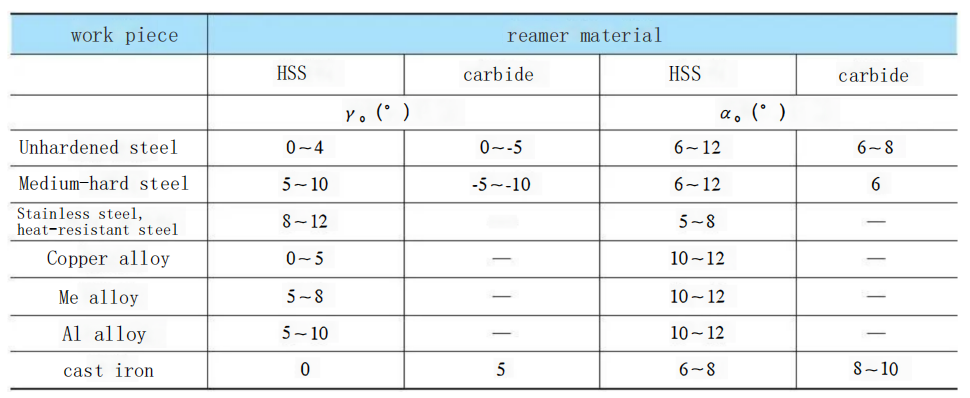

The recommended ranges for the front and back angles are shown in Table 1.

Fig.1 The selection of front and back angles for the reamer

Cutting cone angle

The cutting cone angle 2φ mainly influences the magnitude of feed resistance, tool life, hole machining accuracy, and surface roughness. When the cutting cone angle is small, the feed force is low, and the reamer exhibits good guidance during entry. However, due to the small cutting thickness, significant deformation occurs. Additionally, the increased cutting width makes chip rolling and evacuation challenging, prolonging the entry and exit times. Therefore, to reduce labor intensity and minimize feed force, a larger φ value can be selected to decrease cutting length and maneuvering time. For machining steel, a value of φ is taken as 30°. For machining brittle materials such as cast iron, a range of 6° to 10° is used, while for blind-hole machining, φ is set at 90°.

Rake angle

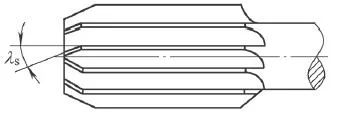

As shown in Figure 5-70, the cutting edge of the high-speed steel straight-fluted reamer is depicted, and its rake angle (λs) is generally set between 15° and 20°. For the manufacturing of cemented carbide reamers, λs is typically set at 0°. When reaming blind holes, reamers with rake angles are still used, but a countersink hole is machined at the end of the reamer to accommodate the chips.

Fig2?The rake angle of the reamer