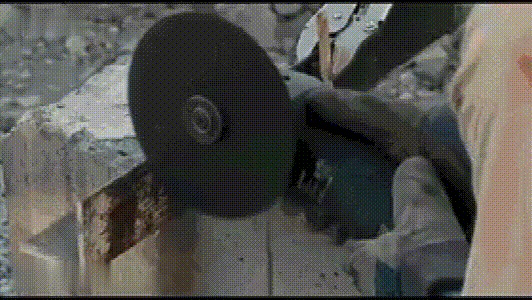

We often use a hand-held angle grinder when cutting some ordinary metals. It’s very convenient and practical. Turn on the power, simply cut the saw, and quickly cut the metal with a little force. If the saw deviates or has burr, just rub it with the saw blade.

Cutting is a very common tool in the grinding process. When it is used, it can be driven by the angle grinder to make it rotate at a high speed. It can grind, slot and cut various workpieces of different materials.

Note that this is an illegal operation. The angle grinder has no shield

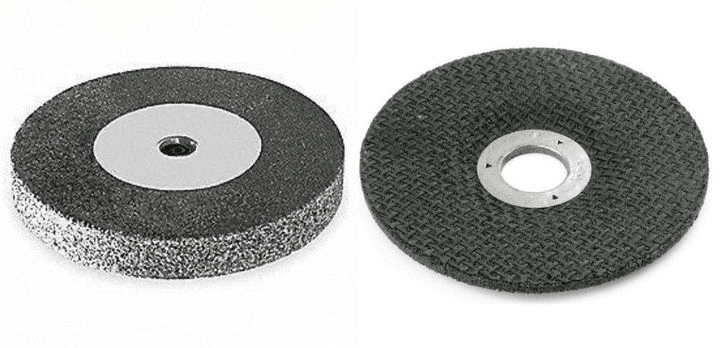

The difference of grinding wheel, cutting blade and grinding blade

In the commonly used cutting tools, grinding wheel, cutting blade and grinding blade are the most used, and their functions and shapes are very similar.

Grinding wheel

Grinding wheel is used for grinding tools. In the manufacturing process, it is made by adding bond, blank pressing, firing and other processes. Generally, the thickness of grinding wheel is thick.

Due to the different abrasives in the grinding wheel and the different manufacturing process, the final grinding wheel is also very different, which will also affect the cutting quality and processing efficiency of the grinding wheel.

According to raw materials (Abrasives), grinding wheel can be divided into ordinary abrasives, such as corundum and silicon carbide, and natural abrasives, such as diamond and boron nitride.

According to bond, grinding wheel can be divided into metal grinding wheel, rubber grinding wheel, resin grinding wheel, ceramic grinding wheel, etc.

Cutting blade

Cutting sheet is used to cut metal sheet, cutting sheet mainly uses glass fiber, resin and abrasives as reinforced bonding materials, has high impact resistance, bending strength and other characteristics, so it is widely used in cutting ordinary steel, stainless steel and other metal and non-metal.

The commonly used cutting pieces are resin cutting pieces and diamond cutting pieces. Resin cutting pieces are mainly made of binder resin and abrasive, which can cut hard metal materials with high efficiency and precision; Diamond cutting blade is composed of matrix and diamond cutter head, which is mainly used for cutting non-metallic materials, such as stone, ceramics and concrete.

Grinding disc

The grinding disc is a thin sheet used for grinding and polishing the surface of the workpiece. The surface of the grinding disc is made of fine alumina and silicon carbide particles. These particles can be used to grind the workpiece by rotating the grinding disc at high speed.

In order to achieve the ideal grinding effect, the abrasive particles of the grinding disc will be evenly distributed, and there are different particle sizes, from tens of mesh to thousands of mesh.

Manufacturing process of cutting piece

It is self-evident that the role of cutting piece for angle grinder is just like the role of teeth for human beings. Once the cutting piece breaks during operation, it is easy to cause serious damage to human body. Therefore, it is very important to produce high-quality and qualified cutting pieces.

Batching process

Resin, abrasive (such as brown corundum), cryolite, adhesive and other raw materials, according to the formula requirements, a certain proportion of raw materials will flow into the raw material barrel through the funnel.

The mixed raw materials should be fully mixed and stirred, and the mixed raw materials should be repeatedly filtered and screened to remove impurities and ensure that the raw material particles are the same size.

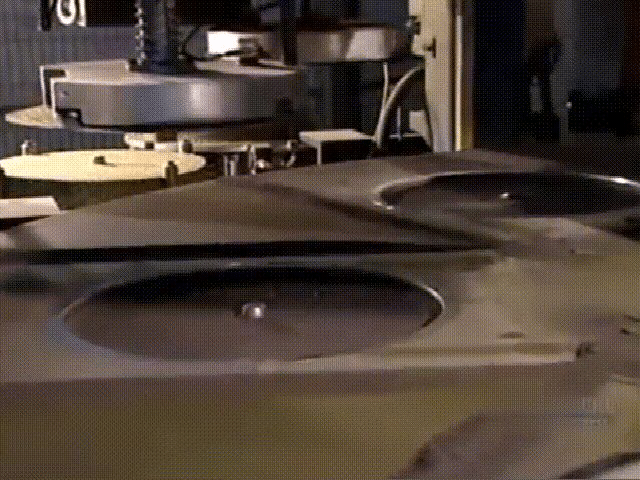

Forming process

In order to solidify the raw materials, the quality of the matrix is also very critical. Firstly, the grid shaped electric board is used as the matrix to support the abrasive, so the electric board matrix needs to be placed at the bottom of the mold when making the cutting pieces.

Then the abrasives are filled on the surface and covered on the glass fiber mesh board. After the filling process is completed, the abrasives mixed with various raw materials are pressed into shape by machine cold pressing method.

After pressing the shaped cutting piece, press the flange in the middle with the machine.

Hardening link

The pressed cutting pieces should be put into the kiln, dried and hardened by high temperature, or dried in the natural environment, or the continuous drying method of combining natural and high temperature.

Test packaging

Sampling cutting pieces for appearance, size, hardness and other strict inspection.

It is also very important to check the maximum speed of the cutting pieces in batches (if the maximum speed of the machine exceeds the maximum speed of the cutting pieces, the cutting pieces are likely to burst in the process of use, and the consequences are very serious.)

Through the manipulator, each piece of the cutting piece is put on the rotating disk, and the glue is dropped on it, so that the packaging trademark is pasted on both sides. At this time, the cutting piece can be sold out of the factory.

Safety of cutting blade

Among all the grinding tools used in the construction, the angle grinder is one of the most potentially dangerous tools. Due to the high speed and fragility of the cutting blade, we can often see all kinds of information about the injury of the grinding wheel, which is mainly caused by the quality of the cutting blade and improper use.

Never use an angle grinder without a protective device. The protective device not only helps to protect you from splashing debris, but also ensures that you will not install grinding wheels beyond the specifications.

If the speed of the cutting blade is too fast, it will burst, and the scattered fragments are enough to cause serious injury or death. The maximum speed of the cutting blade should match the angle grinder, and personal protective equipment should be worn during operation.

The cutting piece shall be selected without deformation, crack and breakage. The cutting piece shall be firmly installed on the angle grinder with a special wrench. When cutting, the cutting piece shall be applied slowly and evenly, and the progress shall not be too fast (excessive force), which is easy to cause the cutting piece to break or damage. If there is abnormal noise, violent vibration and peculiar smell during cutting, the machine shall be shut down for inspection in time, Troubleshooting to avoid accidents.

The rapidly rotating cutting blade is no inferior to all kinds of steel bars and iron blocks. It is a good helper for people in building construction, but the safety in use can not be ignored,

Finally, I would like to remind you that it’s not uncommon for the cutting blade to break and cause injuries. You should be responsible for yourself and your family, and you must install a protective cover when using the angle grinder.