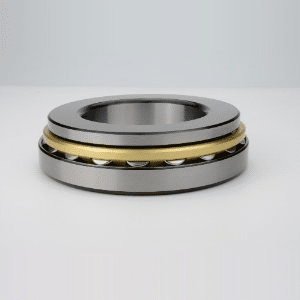

Cemented carbide bearing refers to the bearing made of cemented carbide. The hard alloy bearing has the characteristics of ultra-high wear resistance and high impact resistance. The surface and inner hole of hard alloy bearing can achieve mirror effect.

performance

The main material cemented carbide has a series of excellent properties, such as high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance, etc., especially its high hardness and wear resistance, which are basically unchanged even at 500 ℃, and still have high hardness at 1000 ℃.

Characteristic

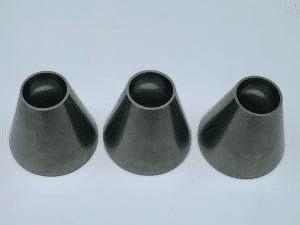

1. With advanced forming technology, various kinds of hard alloy products with complex shapes can be made.

2. The deformation is small and the precision is very high.

3. No machining or only a small amount of machining is required.

The reserves of tungsten resources in Hunan ranks first in China, and tungsten and cemented carbide products account for more than 60% of the total. The scale of domestic tungsten based materials is micrometer. If it is reduced to nanometer level, its properties will change significantly. It has high hardness and high toughness, and becomes a strategic emerging material with priority development in China.

Advantage

Good concentricity, good perpendicularity, high wear resistance and high toughness. It greatly improves the service life of the mould and reduces the use cost of the mould in the production enterprise.

application

Tungsten steel bushing is mainly used for stamping and drawing. Cemented carbide is widely used as cutting tool materials, such as turning tools, milling cutters, planers, drills, boring cutters, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and ordinary steel, as well as for cutting refractory materials such as heat-resistant steel, stainless steel, high manganese steel, tool steel, etc. The cutting speed of the new carbide tool is hundreds of times that of carbon steel.

The main function of cemented carbide bushing is that the bushing is a kind of component to protect the equipment. The use of bushing can effectively reduce the wear between punch or bearing and the equipment, and achieve a guiding role. In the aspect of stamping die, tungsten steel bush is widely used because of its wear-resistant, good finish and no need of frequent replacement, so as to achieve higher utilization rate of equipment and personnel.

In the aspect of drawing, the hard alloy bushing is mainly the drawing of some copper and stainless steel parts. Due to the high frequency of use, it is easy to heat up and produce wear bushing, which makes the punching pin run, the size error of the product and the appearance of the product bad.

With the increase of oil production and the decrease of oil on the shallow surface, in order to ensure the use of oil, people gradually develop into deep wells and deviated wells, but the difficulty of oil production is gradually increasing, so the parts of oil production should have good wear resistance, corrosion resistance or impact resistance.

As a wear-resistant part of petroleum machinery well, cemented carbide bushing has high hardness, good wear resistance and high finish. It has been widely used in modern society and meets the needs of daily use and special performance. Some enterprises adopt spray welding technology to improve the durability and service life of cemented carbide bushing.

The hardness of the spray welded hard alloy bushing can reach HRC60, and the wear resistance is better, which can meet the use requirements of the petroleum machinery industry. However, the spray welded hard alloy bushing needs to be turned to ensure the dimensional requirements and accuracy requirements of the drawings.

Common tool materials include carbide tool, ceramic tool and CBN tool, but carbide tool can be excluded from the hardness of carbide bushing. Although ceramic tool is suitable for machining high hardness workpiece, it is only suitable for finishing process with small allowance. Therefore, the most suitable tool material for machining the cemented carbide bushing is the cubic boron nitride tool.

Producing method

CNC precision angle and inner hole grinder, NC angle and inner hole grinder, precision surface grinder, precision internal and external grinder, centerless grinder are used. The inner hole is grinded and polished into a mirror surface for many times.