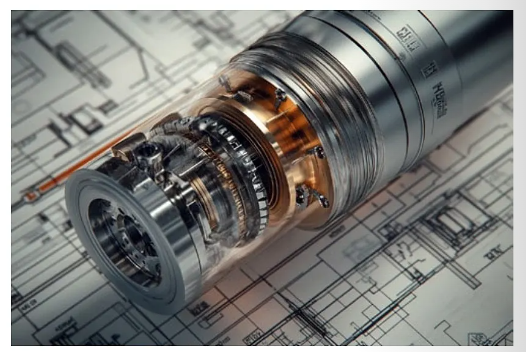

Precision Boring Technology

Precision boring is a hole machining process that pursues ultimate precision. Its main feature is the use of specialized precision boring tools to achieve high-precision machining through precisely controlled cutting parameters. In practical operations, the selection of precision boring tools is crucial and typically needs to be determined based on the properties of the material being machined and the precision requirements, including the material and geometric parameters of the tool. The precision boring process requires strict control of cutting parameters. The cutting speed is generally chosen between 60-120 m/min, the feed rate is usually controlled at 0.1-0.2 mm/r, and the single-cutting depth generally does not exceed 0.5 mm. The selection of these parameters directly affects the machining accuracy and surface quality. At the same time, to ensure machining accuracy, special attention must be paid to the use of coolant, typically using a cutting fluid that provides sufficient cooling and lubrication to ensure temperature stability during the machining process. In specific applications, precision boring is most commonly used in the manufacturing of high-precision parts such as precision bearing housings, cylinder liners, and hydraulic valve bodies. These parts usually require the roundness error of the holes to be controlled within 0.005 mm, and the surface roughness to reach Ra 0.8 μm or better. To achieve such machining precision, it is necessary not only to select high-precision tools and appropriate cutting parameters but also to consider factors such as the accuracy of the machine tool and the rigidity of the fixtures.

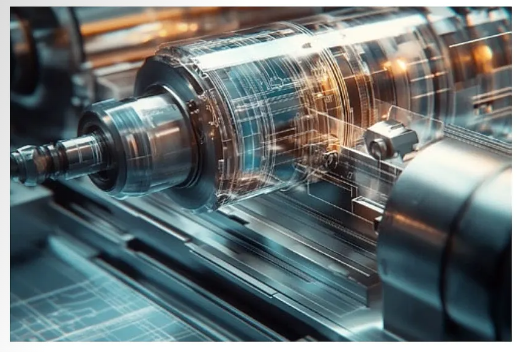

Rough Boring Technology

Rough boring is a machining method that primarily aims to remove material efficiently. During the rough boring process, the operator mainly focuses on the efficiency of material removal, with relatively lower precision requirements. This machining method is usually used as a preliminary process before finish machining, reserving appropriate machining allowances for subsequent finish machining. When selecting cutting parameters, the rough boring process seeks to achieve a larger cutting volume. The cutting speed can generally reach 100-150 m/min, the feed rate can be selected between 0.3-0.8 mm/r, and the single-cutting depth can reach 2-5 mm. Such parameter settings can greatly improve machining efficiency, but they also require the machine tool to have sufficient power and rigidity. In actual operation, special attention must also be paid to chip evacuation, usually requiring the use of high-pressure cooling fluids and special chip evacuation groove designs. Rough CNC boring is mainly applied to the machining of large parts, such as marine engine blocks, large machine tool beds, etc. These parts typically involve a large amount of material removal and have high requirements for machining efficiency. During the machining process, it is necessary to focus on changes in cutting forces and workpiece deformation. If necessary, process measures such as intermediate tempering should be taken to release stresses and ensure machining quality.

Step Boring Process

Step boring is a highly efficient complex hole machining method characterized by its ability to complete the machining of multiple different diameters in one pass. With the use of specially designed step boring tools, the number of tool changes can be significantly reduced, thereby improving machining efficiency. In terms of tool design, special attention must be paid to the relative positions between the cutting edges and the matching of cutting parameters. The selection of machining parameters is particularly important in step boring. Since all the steps are cut simultaneously, the distribution of cutting forces is complex, necessitating a reasonable choice of cutting speed and feed rate. Generally, the cutting speed is chosen between 80-120 m/min, and the feed rate is controlled at 0.2-0.4 mm/r. Additionally, it is necessary to consider the distribution of cutting allowances between the steps to ensure a stable cutting process. Step boring is widely used in the machining of parts with multi-step stepped holes, such as valve bodies and bearing caps. This machining method not only ensures high machining efficiency but also maintains the coaxiality between the steps. In practical applications, special attention must also be paid to the manufacturing and maintenance of the tools, as step boring tools are costly to produce and their service life directly affects the machining cost.

Back Boring Technology

Back CNC boring is an important method for solving hole machining problems under special working conditions. It is mainly used for machining internal holes or back holes that are difficult to access with conventional tools. Back boring tools typically employ special mechanical structures or hydraulic mechanisms to achieve cutting movements in confined spaces. During the back boring process, the operation is challenging and requires precise control of the tool’s feed and expansion. The selection of cutting parameters is relatively conservative, with cutting speeds generally ranging from 40-80 m/min and feed rates between 0.1-0.3 mm/r. At the same time, due to the specialties of the machining position, higher demands are placed on chip evacuation and cooling lubrication. Back boring technology plays a crucial role in the machining of complex parts such as engine crankcases and valve bodies. Although this machining method is relatively less efficient, it is irreplaceable under certain special conditions. In practical applications, special attention must be paid to the selection and maintenance of tools, and it is necessary to develop specialized process procedures and operating protocols.

Five Chamfer Boring Processes

Chamfer boring is an indispensable process in modern machinery manufacturing. It not only improves the appearance quality of parts but more importantly, enhances the assembly performance and service life of the parts. The design of chamfer boring tools needs to consider both radial and axial cutting capabilities, usually achieved with a special blade structure for a stable cutting process. During the chamfer boring process, the selection of cutting parameters should comprehensively consider the size of the chamfer and the surface quality requirements. Generally, the cutting speed is chosen between 60-100 m/min, and the feed rate is between 0.2-0.4 mm/r. It is particularly important to note that the accuracy of the chamfer angle directly affects the assembly quality of the parts, so tool positioning accuracy must be strictly controlled during machining. Chamfer boring technology is widely used in the machining of parts that require a large number of chamfers, such as automobile engine blocks and valve bodies. Through reasonable process design, the chamfering process can be organically combined with other CNC boring operations to improve machining efficiency. In practical applications, attention should also be paid to the detection methods of chamfer dimensions and the establishment of a comprehensive quality control system.

Riepilogo

With the development of modern manufacturing, CNC boring technology continues to innovate. The five main types of boring methods each have their own characteristics and play important roles in different application scenarios. Mastering the technical features and application essentials of these machining methods is of great significance for improving machining quality and efficiency. In actual production, it is necessary to select the appropriate machining method and develop a scientific process plan based on specific machining needs to achieve the desired machining results.