The Impact of Heat Treatment on the Strength of Carbides

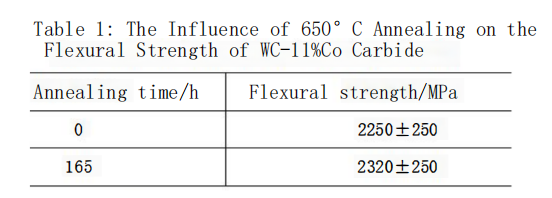

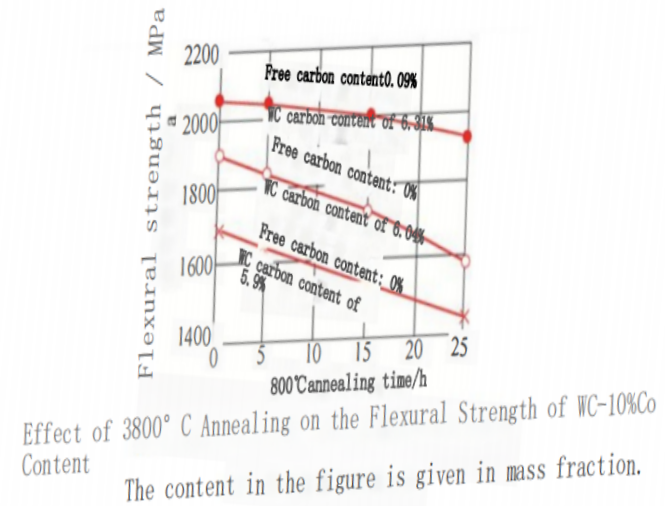

Due to the different solubility of WC in Co at different temperatures, the possibility of achieving precipitation hardening of the binder phase through quenching at the solubilization temperature and subsequent aging is provided. Quenching can suppress the precipitation of WC and the isostructural transformation of Co (Co hexagonal close-packed, Co face-centered cubic). Literature reports indicate that the strength of an alloy with 40% cobalt can increase by about 10% after quenching, but the strength of an alloy with 10% cobalt decreases after quenching. Annealing can also cause a decrease in the strength of the alloy, as shown in Table 1 and Figure 1.

The Impact of Heat Treatment on the Hardness of Carbides

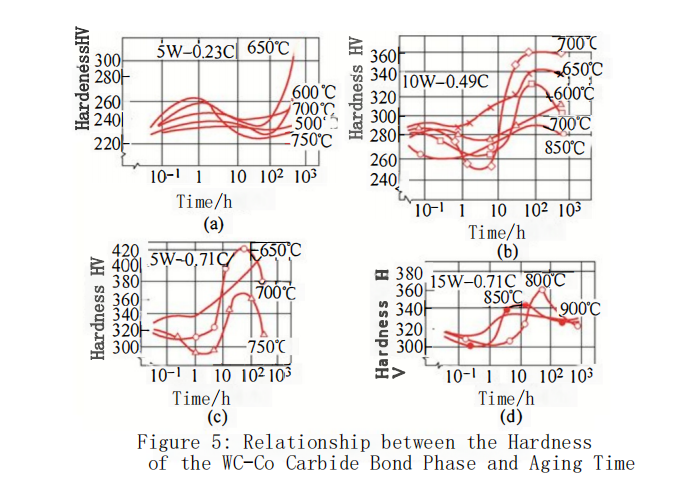

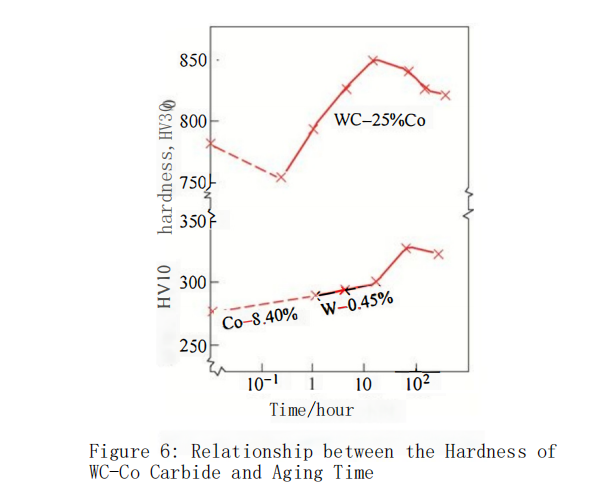

During the aging process of WC-Co alloy, the precipitation of Co3WCX and the formation of a dense microstructure occur, resulting in an increase in the hardness of the alloy. However, when the subsequent transformation leads to the precipitation of Co3W, the hardness of the alloy decreases. Experimental data is illustrated in Figure 5 and Figure 6.

While the presence of Co3WCX after heat treatment slightly increases the hardness of the alloy, considering the extended heat treatment time and the decrease in flexural strength, it is believed that the precipitation of the Co3WCX phase for dispersion strengthening of the binder phase is not an effective method for developing new grades. Alternative approaches should be explored. Aging treatment involves maintaining the alloy at a specific temperature for a certain duration, allowing it to reach a thermodynamic equilibrium state. This can lead to the precipitation of phases that enhance hardness in the alloy, such as the Co3WCX phase. Aging treatment has a positive impact on improving the hardness and strength of carbides.

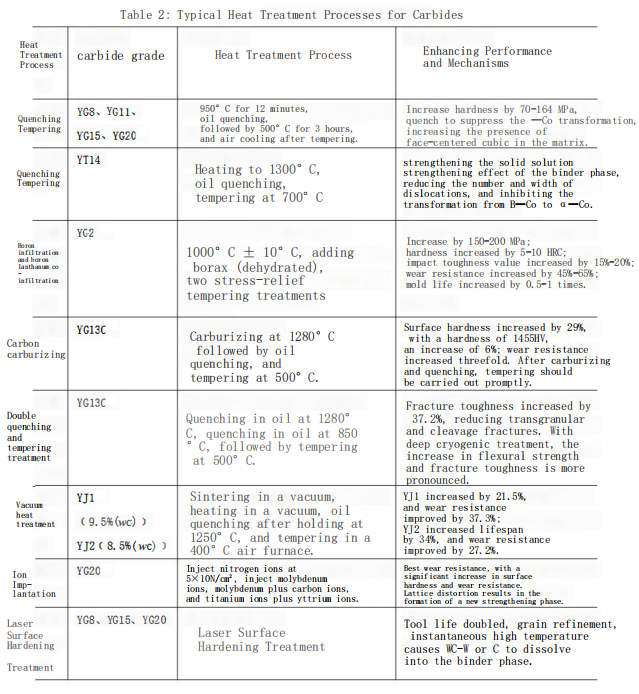

Applying different heat treatments for various grades

To enhance alloy performance, specific heat treatment processes tailored to different grades of Carbides are essential for achieving optimal properties. We have consolidated typical results of heat treatment for Carbides in Table 2 for your reference.

Typical results of heat treatment for carbideS

Conclusione

Firstly, heat treatment has a significant impact on the crystal structure and grain size of carbides. By controlling the heating and cooling rates, the growth and arrangement of crystals can be adjusted, affecting the hardness and strength of alloy. For example, an appropriate quenching process can create a dense lattice structure, increasing the hardness of alloy.

Secondly, heat treatment also influences the wear resistance of alloy. By adjusting the elemental composition and distribution of phases in the alloy, the surface performance of hard alloys can be improved, making them more resistant to wear and corrosion. This is crucial for the performance of hard alloys in cutting, grinding, and other high-wear applications.

Additionally, heat treatment can also adjust the toughness and impact resistance of hard alloys. Through proper aging treatment, the binder phase in the alloy can be optimized, enhancing its bending and impact resistance. This is of great significance for the application of hard alloys in high-load and impact environments.

Overall, by precisely controlling the heat treatment process, comprehensive improvements in the performance of hard alloys can be achieved, making them better suited to the requirements of the industrial and manufacturing sectors.