Ces dernières années, la technologie de production de carbure cémenté à grains ultrafins s'est développée rapidement, en particulier...

La taille des grains de WC est d'une grande importance pour les propriétés de frottement et d'usure...

Les carbures sont composés de carbures réfractaires présentant une résistance à la compression, une dureté et un module d'élasticité élevés, qui...

Le pressage isostatique à chaud à basse pression (HIP) est un nouveau procédé de frittage développé dans les pays développés occidentaux...

De nombreuses structures en carbure WC-Co sont soumises à des charges thermomécaniques et doivent...

Les carbures contiennent principalement deux types d'additifs : l'un est des carbures de métaux réfractaires et l'autre...

La recherche et le développement de plans cristallins dans les carbures cémentés sont l'un des points chauds...

Les outils de coupe en carbure cémenté sont très courants dans les opérations de coupe, et la sélection correcte de...

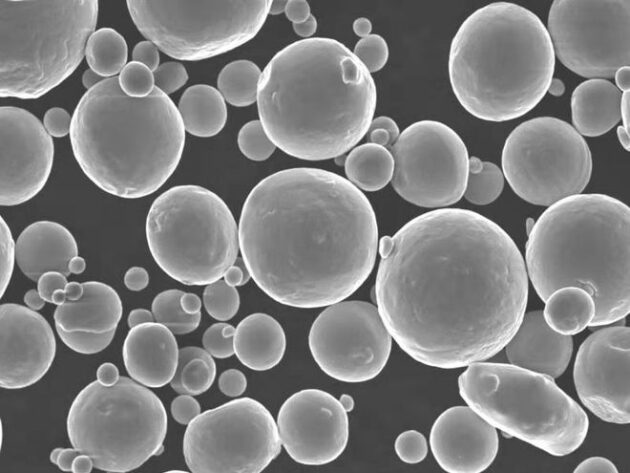

Les carbures Nano-WC-Co, connus pour leur résistance et leur dureté élevées, représentent une direction prometteuse pour...

Ces dernières années, les matériaux en carbure de tungstène (WC) YG8 ont suscité une attention croissante en raison de leur excellent...