Comment la chaleur de coupe est générée

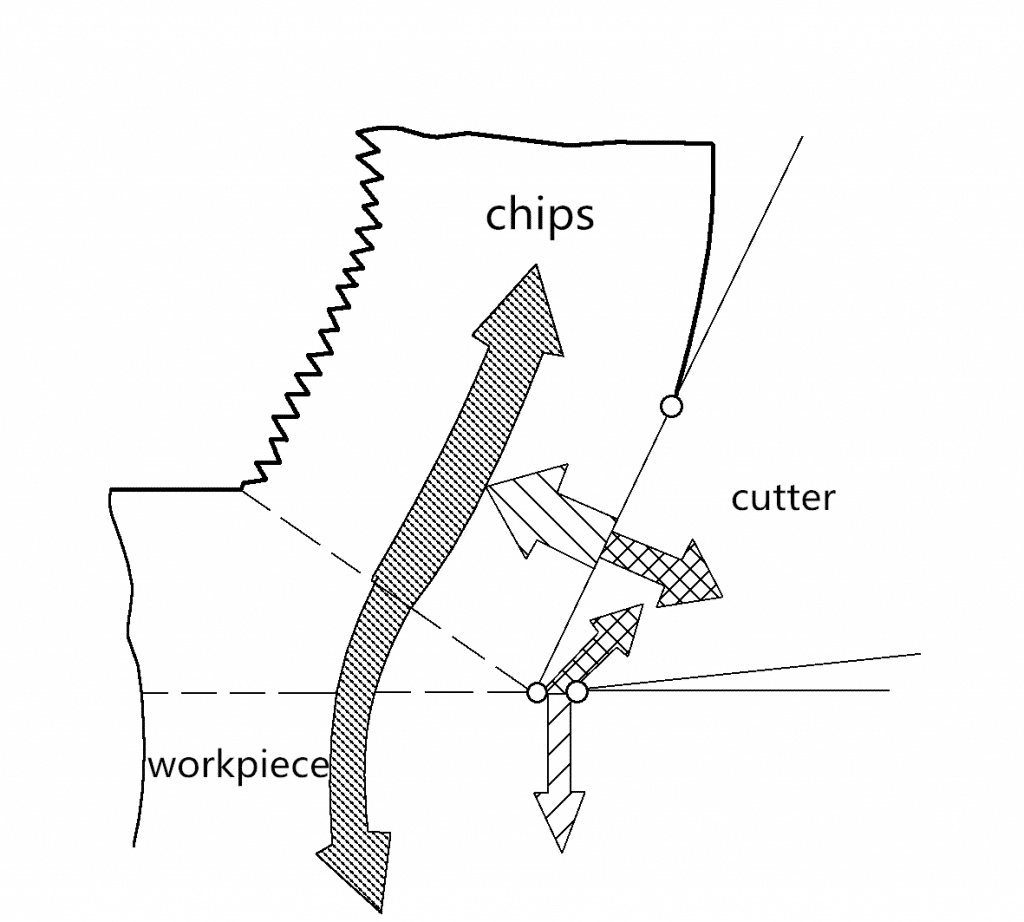

The cutting heat is generated in three deformation zones. During the cutting process, the metal deformation and friction in the three deformation zones are the root cause of the cutting heat. Most of the work of deformation and friction during the cutting process is converted into cutting heat. The figure below shows the location of the heat generated by the cutting heat and the dispersion.

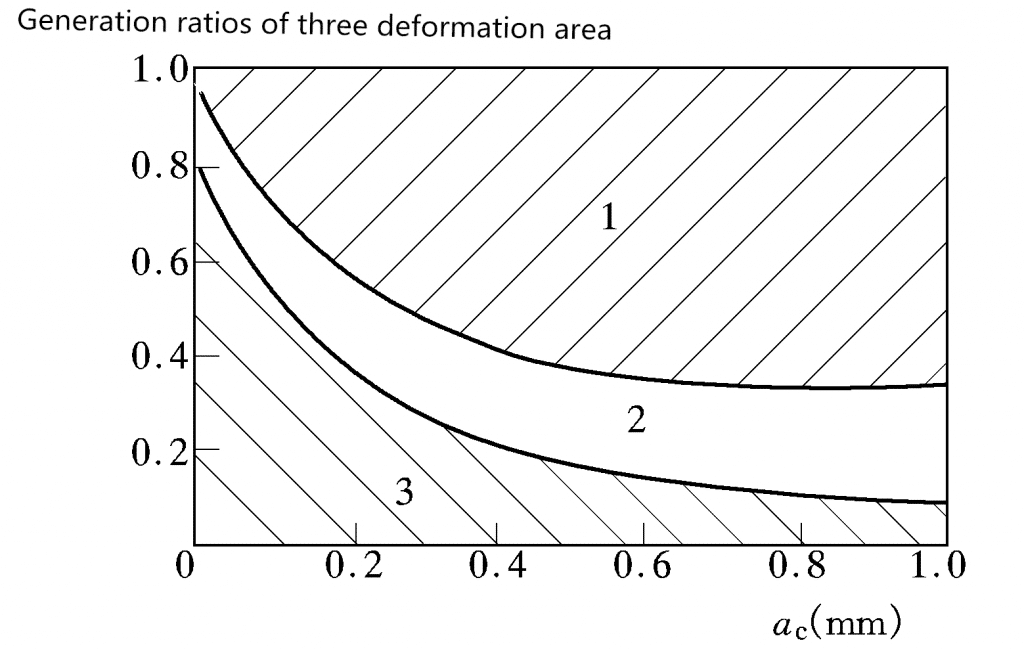

The amount of heat generated by the cutting heat and the proportion of heat generated in the three deformation zones vary with the cutting conditions. When processing plastic metal materials, when the flank wear amount is not large, and the cutting thickness is large, the heat generated in the first deformation zone is the most. When the tool wear amount is large, and the cutting thickness is small, the third deformation zone The proportion of heat generation will increase. The following diagram shows the ratios of heat generated in the three deformation zones to the thickness of the cut when machining nickel, chromium, molybdenum, vanadium and steel with a carbide tool.

Diagram 1. three ratios of heat generated by nickel, chromium, molybdenum

- First deformation zone 2-second deformation zone 3-third deformation zone

When processing brittle materials such as cast iron, due to the formation of breaking chips, the contact length of the chip is small, the friction on the rake face is small, and the proportion of heat generation in the first and second deformation zones is decreased. Therefore, the proportion of heat generated in the third deformation zone is relatively increased. .

The heat of cutting generated during the cutting process is dissipated outside the cutting zone by the chips, the workpiece, the tool and the surrounding medium. The proportion of heat transfer by each route is related to the cutting form, the tool, the workpiece material and the surrounding medium. 50%~86% of the heat in the turning process is taken away by the chip, 40%~10% is transferred into the turning tool, 9%~3% is introduced into the workpiece, and about 1% is introduced into the air. When drilling, 28% of the heat is taken away by the chips, 14.5% is transferred into the tool, 52.5% is introduced into the workpiece, and about 5% is introduced into the surrounding medium.

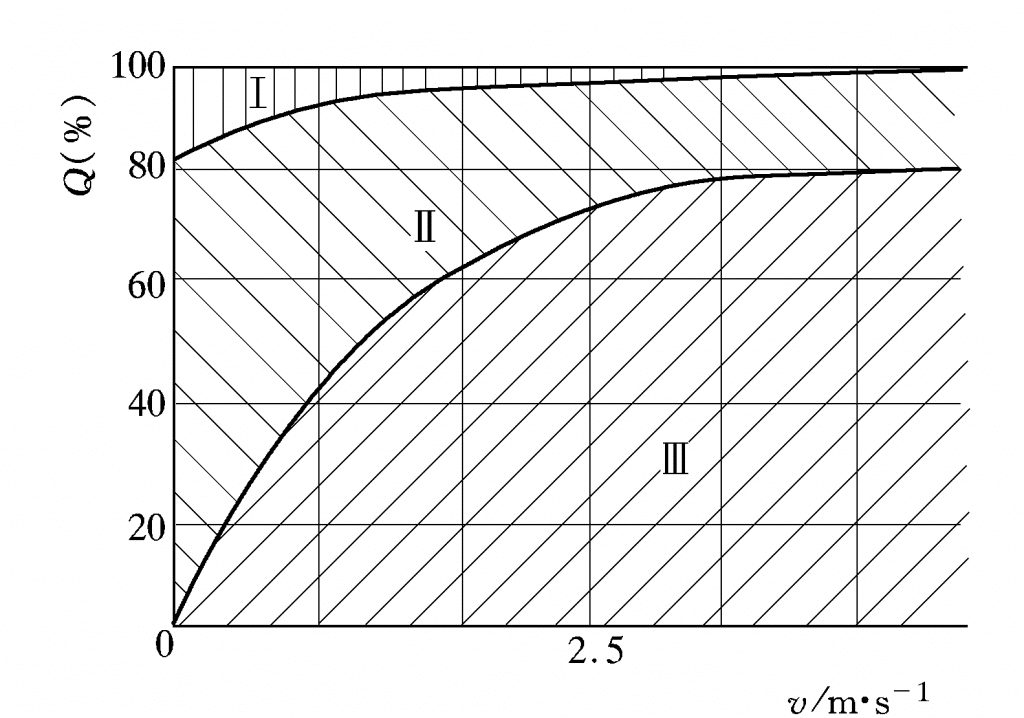

In addition, the cutting speed “υ” also has a certain influence on the heat transfer ratio of each route. The higher the cutting speed, the less heat is carried away by the chips. The chart below shows the effect of enthalpy on the heat transfer.

Dia.3 The cutting velocity’s influence on cutting heat transfer

I—Tool II—Workpiece III—Chip

Cutting heat and its effect on the cutting process

The heat generated by cutting a workpiece with a tool is called cutting heat. Cutting heat is also an important physical phenomenon in the cutting process, which has many effects on the cutting process. The heat of the cutting is transferred to the workpiece, which causes thermal deformation of the workpiece, thus reducing the machining accuracy. The local high temperature on the surface of the workpiece deteriorates the quality of the machined surface.

The heat of cutting that is transmitted to the tool is an important cause of tool wear and tear. Cutting heat also affects cutting productivity and cost by causing tool wear. In short, cutting heat has direct and indirect effects on the quality, productivity and cost of cutting. Research and master the general rules of heat generation and change of cutting heat, limit the adverse effects of cutting heat to the allowable range, and cut the machining. Production is of great significance.

Main factors affecting cutting temperature

First, the influence of cutting amount on cutting temperature

1. Cutting speed has a significant effect on cutting temperature. Experiments have shown that as the cutting speed increases, the cutting temperature will increase significantly.

2. The feed rate f also has a certain influence on the cutting temperature. As the feed rate increases, the amount of metal removal per unit time increases, and the cutting heat generated during the cutting process also increases, causing the cutting temperature to rise.

However, the increase in cutting temperature as the feed rate increases is not as significant as the cutting speed.

3. The depth of cut ap has little effect on the cutting temperature. Since the heat generated in the cutting zone increases proportionally after the depth of cut ap increases, the increase in the cutting temperature is not significant because of the improved heat dissipation conditions.

Laisser un commentaire

Votre adresse de messagerie ne sera pas publiée.