Research on the grinding process of WC-based cemented carbide mainly focuses on grinding speed, grinding time, and ball-to-material ratio, with less research on the shape of the grinding media. Therefore, this paper selects grinding media of different shapes, prepares WC-10%Co cemented carbide, and studies the influence of the shape of the grinding media on the micro-morphology of the powder, the morphology, and performance of the alloy, thereby providing a reference for the development of a reasonable grinding process.

Experimental Methods and Procedures

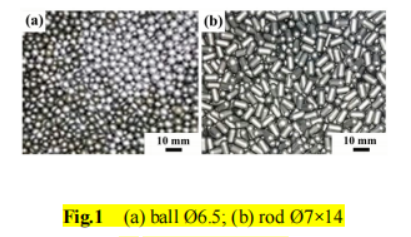

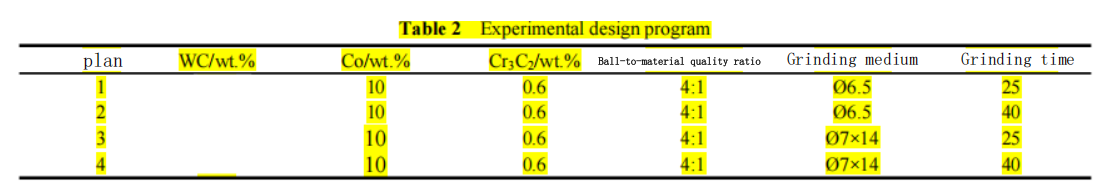

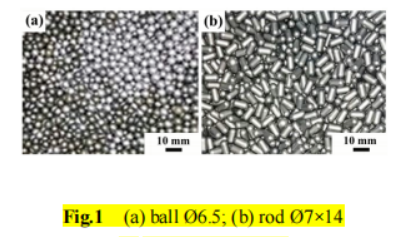

The technical parameters of the WC powder used are shown in Table 1. Wet grinding was carried out using a cemented carbide wet mill jar. WC powder, Co powder, and Cr?C? were proportioned according to the experimental design plan in Table 2, with a ball-to-material mass ratio of 4:1. Different WC-Co grinding media (spherical 06.5 and rod-shaped 07×14, as shown in Figure 1) were selected for wet grinding and mixing in a drum mill at 90 r/min. The addition of wet grinding medium alcohol was 280 mL-kg1, the binder was PEG4000 (2.0 wt.%), and the grinding time was 25h and 40h. After grinding, the slurry was placed in a vacuum drying oven to dry. After screening, the mixture was pressed into green bodies of 6 mm×10 mm×15 mm specification at a pressure of 150 MPa. The green bodies were dewaxed and sintered in a sintering furnace. Dewaxing was carried out using a slight positive pressure, with a temperature range of 180-500°C. The sintering temperature was 1450°C, with a holding time of 2h, and finally, the cemented carbide samples were obtained.

The micro-morphology of the samples was observed using a German Zeiss EVO 18 scanning electron microscope, and the average grain size of the alloy was measured using the intercept method. The specific surface area of the powder was determined using an American Conta Monosorb MS specific surface area meter. The density of the samples was obtained by the Archimedes method, and the relative density was calculated. The coercive force (Hc) of the samples was tested using a coercive force analyzer (Zhongda-ZDHC40). The transverse rupture strength (TRS) of the samples was tested according to the GBT 3851-1983 B standard using a Sansi UTM5105 electronic universal testing machine. The fracture toughness of the samples was tested according to the ASTM B771 standard using a Sansi UTM5105 electronic universal testing machine. The hardness of the samples was tested using a Rockwell hardness tester (Wilson-RS74).

Analysis and Discussion of Results

Analysis and Discussion of Results

Figure 2 shows the SEM images of powders prepared with different shapes of grinding media and different grinding times. As shown in the figure, with the increase of grinding time, the average particle size of the powder gradually decreased whether using grinding balls or rods. This is because as the grinding time increases, the breaking and extruding effects of the grinding media and the mill jar on the powder also deepen continuously. The more energy produced during grinding, the more intense the impact and shear the powder receives, leading to the generation of a large number of dislocations. The particles continuously break along the particle interfaces and grain boundaries, resulting in the continuous refinement and homogenization of the powder.

The state of cemented carbide powder during time ball milling less than 40 hours

When the grinding time reached 40h, the specific surface area of the powder obtained by rod grinding was 2.01 m2·g1, which was higher than the 1.85 m2·g1 obtained by ball grinding. The finer the powder, the larger the specific surface area, and the higher the powder activity, with greater surface energy, making it easier to agglomerate together and adsorb oxygen. This is beneficial for pore shrinkage and the disappearance of vacancy clusters during sintering, achieving densification.

Powder status after ball milling time more than 40h

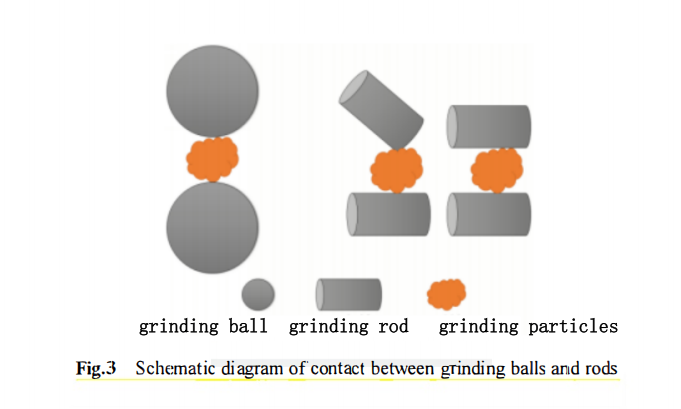

After the grinding time reached 40h, the powder produced using grinding balls had some coarse particles and generated more broken powder, which adhered to the surface of larger particles or agglomerated together. Additionally, the powder produced using grinding rods appeared rounder in appearance, while the powder produced using grinding balls had an irregular shape. This is due to the different contact methods of the two shapes of grinding media, as shown in Figure 3 for a schematic of the contact between grinding balls and rods. The contact method between grinding balls is point contact, which easily produces a larger force at the points of contact, leading to a higher likelihood of breakage. Moreover, during the movement of the grinding balls, the contact with the powder is non-selective, resulting in low precision of the breakage. This leads to the powder ground with balls being irregularly broken, producing a large amount of broken powder. In contrast, the contact method between grinding rods is a combination of line contact and point contact. During the grinding process, the force applied at the points of contact is more dispersed, avoiding the generation of large forces and thus preventing over-grinding. The grinding rods have a selective breaking action that breaks coarse particles while protecting fine particles. In the grinding process, the coarse particles are necessarily the first to be ground, making the probability of coarse particle powder being ground higher than that of fine particle powder. This results in the powder ground with rods being more uniform.

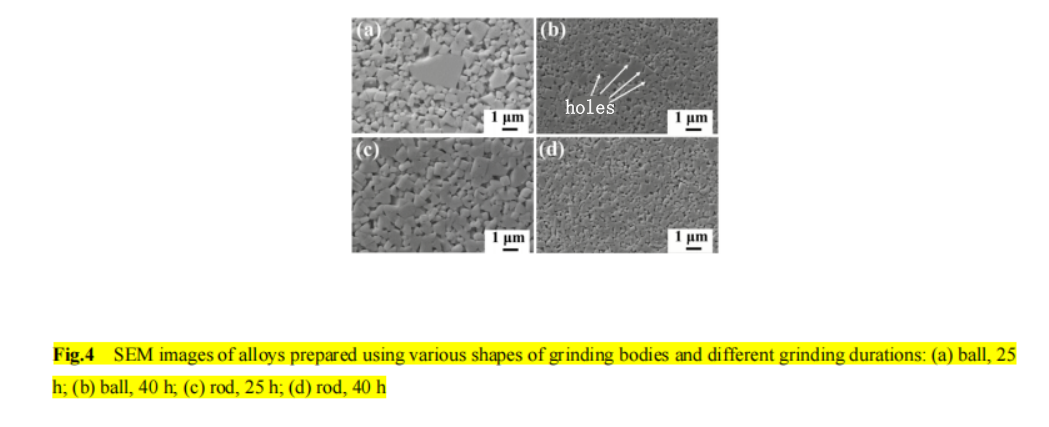

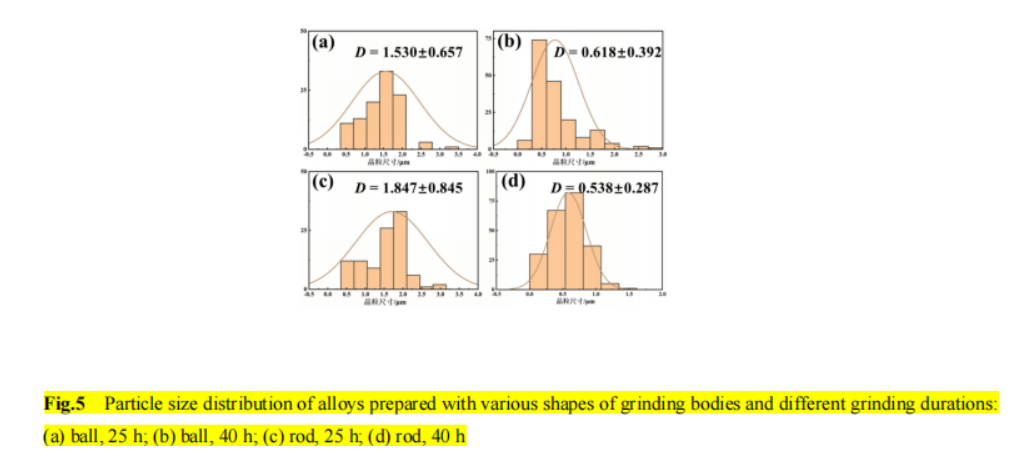

Figure 4 shows the SEM images of alloys prepared with different shapes of grinding media and different grinding times. It can be observed from the figure that WC grains are randomly distributed in the Co phase, with shapes typical of irregular rectangles and triangles . As the grinding time reaches 40h, the size of the WC grains is reduced to varying degrees, and the cemented carbide grains obtained with grinding rods are finer and more uniform. In contrast, the alloy grains obtained with grinding balls exhibit a significant issue of coarse grain inclusion, with obviously large grains present. It can also be found in Figure 4(b) that there are a large number of pores near the large grains, and the presence of large grains and numerous pores will inevitably affect the mechanical properties of the alloy. Figure 5 shows the particle size distribution of alloys prepared with different shapes of grinding media and different grinding times. After the grinding time extends from 25h to 40h, the average grain size (D) of the spherical medium decreases from 1.530 μm to 0.618 μm, and the average grain size of the rod-shaped medium decreases from 1.847 μm to 0.538 μm. The distribution curve in the graph becomes narrower, and the standard deviation significantly decreases, indicating that the grains become more uniformly distributed as the grinding time increases. Combined with Figure 4, it can be found that after 40h of grinding, the alloy grains obtained with grinding rods are finer and more uniform, while the cemented carbide grains obtained with grinding balls have coarse grain inclusion, with obviously large grains observable. This is because the grinding intensity of the grinding balls is higher than that of the grinding rods, which easily produces broken powder and irregular large particles, leading to abnormal grain growth during sintering.

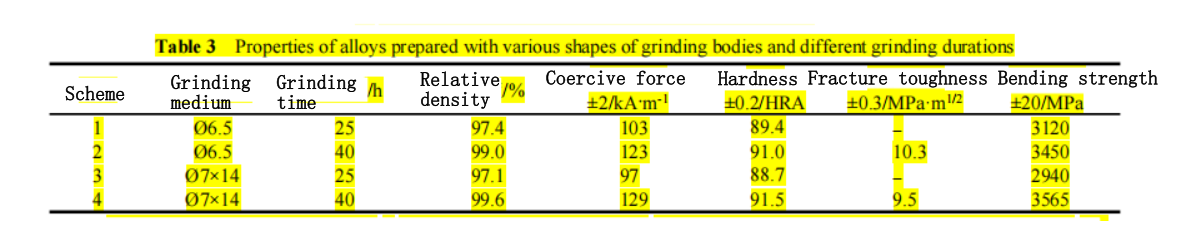

Table 3 shows the properties of cemented carbides prepared with different shapes of grinding media and different grinding times. After 25h of grinding, the relative density of the alloy ground with grinding balls is 97.4%, which is higher than the 97.1% of the alloy ground with grinding rods; when the grinding time is increased to 40h, the relative density of the alloy ground with grinding rods is 99.6%, higher than the 99.0% of the alloy ground with grinding balls. The main factors affecting the relative density of cemented carbide include pores, specific surface area, carbon content, and composition. As the grinding time is extended, the relative density improves, which could be due to the alloy grains becoming finer and more uniform with the extended grinding time, resulting in reduced pores and increased density. After 40h of grinding, the alloy ground with grinding balls has large grains, and as observed in Figure 4(b), there are a large number of pores near the large grains, which weakens the density. The alloy ground with grinding rods has finer and more uniform grains, and the powder has a larger specific surface area and higher activity, which is beneficial for pore shrinkage and the disappearance of vacancy clusters during sintering, promoting densification and thus achieving a higher relative density.

It can be seen from Table 3 that as the grinding time extends, the hardness and bending strength of the alloys ground with both types of grinding media increase. At 40h of grinding time, the hardness and bending strength of the alloy ground with grinding rods are higher. First, due to the dispersion and mixing of agglomerated mixtures during grinding, as the grinding time increases, the WC grains become finer, and the finer WC grains will reduce the contact between each other, prompting an increase in the average free path of the Co phase, with a more uniform distribution, increasing the effective deformation range, and thereby increasing the hardness and bending strength of the cemented carbide . The alloy ground with grinding rods for a longer time has finer and more uniform grains, with a better fine-grain strengthening effect, so at 40h of grinding time, the hardness and bending strength of the alloy ground with grinding rods are higher. Secondly, hardness and bending strength are also closely related to density and pores; the presence of pores will weaken the alloy’s ability to resist damage, according to the empirical formula:

![]()

In the formula: σ represents the strength of the cemented carbide corresponding to the porosity P; σ0 represents the strength of the alloy when the porosity is zero; b is a constant; P is the porosity. Under the same conditions, the higher the porosity of the material, the smaller the effective area that bears the load, resulting in a lower corresponding material strength. Therefore, as shown in Figures 4 and 3, the alloy ground with grinding balls has large grains, and there are a large number of pores near the large grains, which reduces its density. The alloy ground with grinding rods has finer and more uniform grains, fewer pores, and greater density. Hence, as the grinding time increases, the hardness and bending strength of the alloy are enhanced, with the alloy ground with grinding rods being higher.

Finally, according to the Hall-Patch formula, the relationship between the alloy strength and grain size is as follows:

![]()

In the formula, σ represents the strength of the cemented carbide ; d represents the grain size. Combining Figures 2 and 4, when the grinding time reaches 40h, the grains ground with rod-shaped media are finer and more uniform, and the density is also higher. Therefore, the more refined the alloy grains become, the stronger the fine-grain strengthening effect will be, leading to a higher bending strength and hardness of the alloy. In contrast, the alloy prepared at a grinding time of 25h, especially when using grinding rods, results in coarser grains, lower density, and more pores. This leads to a lower average free path of the Co phase, uneven distribution of the binder phase, and a shorter effective deformation range. Consequently, the bending strength and hardness of the alloy are both low.

For the fracture toughness of the samples, it can be observed from Table 3 that at a grinding time of 40h, the fracture toughness of the alloy ground with rod-shaped media is 9.5 MPam1/2, which is lower than that of the cemented carbide ground with spherical media at 10.3 MPam1/2, and this is inversely proportional to the hardness relationship between the two. Combining with Figure 4, it can be found that the alloy ground with grinding balls may have coarse grains, which hinder crack propagation, making transgranular fracture more likely to occur at large grains. Moreover, the larger the grain size, the stronger the ability to accommodate moving dislocations, and the greater the resistance to crack propagation. The cemented carbide ground with grinding rods has finer and more uniform grains, mainly exhibiting intergranular fracture, making crack propagation easier and leading to a decrease in fracture toughness. Therefore, the fracture toughness of the alloy ground with grinding balls is higher than that of the alloy ground with grinding rods.

It can also be known from Table 3 that as the grinding time increases, the coercive force of the alloy ground with grinding balls increases from 103 kA m-1 to 123 kA m-1, and the coercive force of the alloy ground with grinding rods increases from 97 kA m-1 to 129 kA m-1. According to literature reports, the coercive force of the alloy has the following relationship with the WC grain size and Co content:

In the formula, Hc represents the coercive force of the alloy; dwc represents the grain size of WC; Wc represents the mass fraction of Co in the alloy. In this experiment, the Co content is the same for all samples. Therefore, it can be understood that the thinner the grain size of the alloy, the smaller the thickness of the magnetic bonding phase will be, and the more evenly it will be dispersed, leading to an increase in coercive force. When the grinding time reaches 40h, whether using grinding balls or rods, the coercive force of the cemented carbide is significantly improved due to the refinement of the grains with increased grinding time. Since the alloy ground with grinding rods has finer and more uniform grains, whereas the alloy ground with grinding balls has larger grains and poorer uniformity, the coercive force of the alloy ground with grinding rods is higher.

Conclusions

WC-10%Co cemented carbide with the same composition was prepared using grinding media of different shapes. The micro-morphology of the powder and the morphology and properties of the alloy were studied and analyzed, and the following conclusions were drawn:

Compared to grinding for 25h, the powder ground for 40h with both shapes of grinding media is more refined. However, the grinding intensity of the grinding balls is higher than that of the grinding rods, leading to the presence of coarse grains and broken powder in the ground material, which affects the properties of the alloy.

The grain size of the alloy ground for 40h with both shapes of grinding media is finer and more uniform than that ground for 25h. Compared to the alloy ground with grinding balls, which has abnormally large grains deteriorating the grain distribution and properties of the alloy, the alloy ground with grinding rods has finer and more uniform grains, enhancing the properties of the alloy. The alloy ground with grinding rods for 40h can achieve better properties: relative density of 99.6%, coercive force of 129 kA·m-1, hardness of HRA 91.5, fracture toughness of 9.5 MPa·m1/2, and bending strength of 3565 MPa.