Fig. 1 Relationship between WC-Co hardness and WC grain size and Co content

WC-Co is traditionally made via injection molding, extrusion, or powder metallurgy, but these methods face limitations in geometry, efficiency, and cost. Additive manufacturing (AM) enables complex designs (e.g., internal cooling channels) with lower time/cost. Key AM methods for WC-Co include SLM and BJAM, though challenges like cracks, porosity, and dimensional accuracy persist. Post-processing (e.g., HIP, machining) is often needed, adding cost.

Fig2. SEBM WC-13Co samples

In this review, the current status of additive manufacturing of WC-Co hardmetals is reviewed. The advantages and disadvantages of different AM processes used for producing WC-Co parts, including selective laser melting, binder jet additive manufacturing, selective electron beam melting, 3D gel-printing, and fused-filament fabrication are discussed. The studies on microstructures, defects, and mechanical properties of WC-Co parts manufactured by different AM processes are reviewed. Finally, the remaining issues and suggestions on future research on additive manufacturing of WC-Co hardmetals are put forward.

Additive manufacturing processes used for WC-Co hardmetals

Additive manufacturing processes used for fabrication of WC-Co hardmetals include the following: (1) selective laser melting (SLM, also called laser powder bed fusion, L-PBF), (2) selective electron beam melting (SEBM, also called electron beam powder bed fusion, E-PBF), (3) binder jet additive manufacturing (BJAM), (4) 3D gel-printing (3DGP), and (5) fused filament fabrication (FFF).

SLM and SEBM

SLM is currently the most promising AM technology for metal materials, which selectively melts powder layer by layer with a laser beam (as illustrated in Fig. 2) to form dense parts with good mechanical properties comparable to casting or forging . Subsequently, post-processing is sometimes essential for SLM due to the need to reduce defects and eliminate residual stress .

Fig. 3 Schematic diagram of SLM process

SEBM is similar to SLM, but also different in some aspects. For metal AM, SLM is more widely used than SEBM mainly due to lower equipment cost. SEBM can only be used for conductive materials since electric conductivity is required . The most important difference is the heat sources. The heat source of the SEBM is an electron beam, which can be controlled by a magnetic field and causes the scanning speed to be much higher than the SLM .

Cost/accessibility: SLM has lower equipment costs and only requires argon (vs. SEBM’s vacuum)

Materials: SEBM limited to conductive materials

Process: SEBM’s pre-sintering reduces support structures, offering greater geometric freedom

Temperature: SEBM operates at higher temperatures

BJAM

Binder Jet Additive Manufacturing (BJAM) is a powder-based process where layers are selectively bound by liquid binder to form a “green part” (Fig. 3), later sintered (>1400°C for WC-Co) for strength. Unlike melting-based methods, BJAM enables complex geometries but typically yields porous parts, sometimes requiring metal infiltration (e.g., Co into WC skeleton). However, precise Co content control remains challenging due to the infiltration process.

Fig. 4 Schematic diagram of BJAM process

Compared to SLM, BJAM is more cost-effective but involves three steps, with unavoidable sintering shrinkage requiring design-stage compensation that limits dimensional precision. SLM’s rapid cooling creates uneven microstructures with high residual stress, often leading to porosity and micro-cracks. For powder-based AM (including SLM/BJAM), powder flowability is critical – requiring spherical, defect-free 10-50μm particles, with spray-dried pre-alloyed WC-Co powder preferred for non-infiltrated BJAM/SLM, while pure WC powder suits infiltrated BJAM . Moisture control is essential to prevent high-temperature porosity.

3D gel-printing

3D gel-printing (3DGP) merges gel casting and FDM, where powder is mixed into a slurry with organic solvents, then extruded through a nozzle (Fig. 4) alongside initiator/catalyst via compressed air. The deposited slurry polymerizes into a green part, later debonded and sintered. Unlike powder-bed methods, 3DGP eliminates fluidity requirements and material waste since no powder spreading is needed.

Fig. 5 Schematic diagram of 3D gel-printing (3DGP), (1) screw extruder, (2) nozzle, and (3) green body

Fused filament fabrication of hardmetal

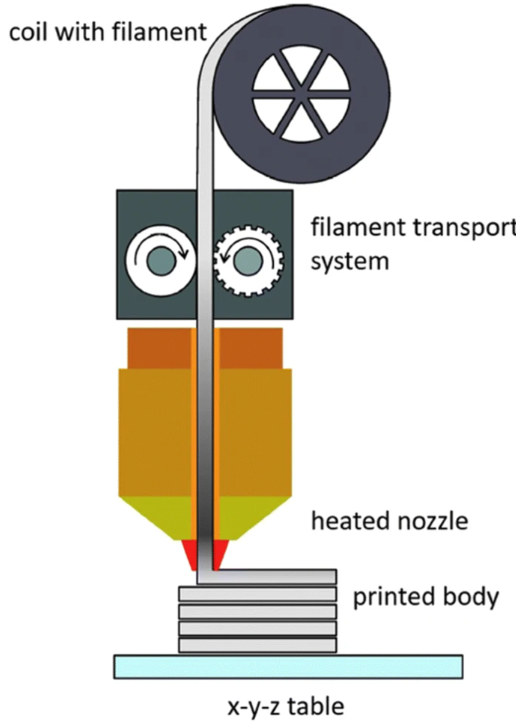

Fused Filament Fabrication (FFF) is an AM technique akin to 3DGP but uses powder-based filaments instead of slurry. The process involves mixing powder with binders, extruding into filaments via capillary rheometer, then depositing through a nozzle to build green parts (Fig. 5). Post-printing, a unique two-step debonding (solvent immersion followed by thermal treatment) precedes final sintering.

Fig. 6 Schematic diagram of fused filament fabrication (FFF)

Resumen

In this paper, the current status of additive manufacturing of WC-Co hardmetals is reviewed. The advantages and disadvantages of different AM processes used for producing WC-Co parts, including selective laser melting (SLM), selective electron beam melting (SEBM), binder jet additive manufacturing (BJAM), 3D gel-printing (3DGP), and fused filament fabrication (FFF) are discussed. The studies on microstructures, defects, and mechanical properties of WC-Co parts manufactured by different AM processes are reviewed.

Fig7. Shrinkage of the BJAM printed WC-12Co part after sintering

Resumen

In conclusion, the above five additive manufacturing processes can be divided into two types: selective melting process and shaping-debonding-sintering (SDS) process. Selective melting processes include SLM and SEBM, which make parts by melting powder with a heat source. This type of process is very simple and enables one-step molding. But sometimes post-processing is needed to eliminate stress and defects. The SDS process includes BJAM, 3DGP, and FFF.

The SDS type processes are characterized by forming a green part with organic compounds as binder and then sintering. Compared with the selective melting process, the SDS process is more complicated. Because SLM, SEBM, and BJAM all contain a powder spreading step, all three processes require the powder to have good flowability. While 3DGP and FFF prepare powders as slurry and filament for printing, there is no need for powder flowability. The application of SEBM is limited by its very high equipment cost. SLM suffers from uneven microstructure, carbon loss, and evaporation of Co.