The aviation industry has maintained a good development trend and has broad development prospects. With the continuous and steady increase of market demand and the continuous development and operation of new aircraft, the manufacturing demand of various aerospace products is increasing year by year, forcing aerospace manufacturing enterprises to greatly improve production and processing efficiency.

At present, high-strength aluminum alloy materials (such as 6000 and 7000 Series) are most commonly used in typical structural parts of aerospace, and new aluminum lithium alloys are also more and more widely used (such as 2050 and 2060). Although aluminum alloy has good machinability, structural parts of aerospace products have the characteristics of complex shape and structure, large amount of material removal, thin wall and easy deformation, and have higher requirements for parts machining accuracy, quality and machining efficiency. Therefore, how to realize the efficient processing of aluminum alloy structural parts has been studied and pursued by many aerospace manufacturing enterprises. The aerospace industry has always been a star field with rapid development of Sandvik’s performance. In view of this demand of the market and customers, Sandvik’s Kelman has launched a series of products and schemes for efficient processing of aerospace aluminum alloy structural parts.

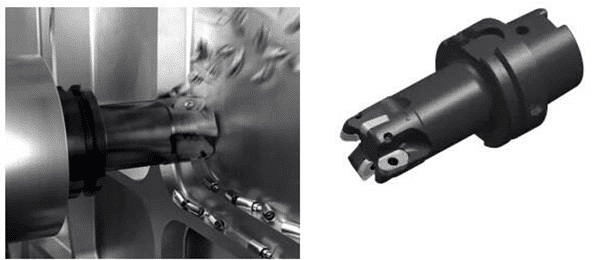

Ral90 heavy duty aluminum milling cutter![How to efficiently process aerospace aluminum alloy structural parts 3 How to efficiently process aerospace aluminum alloy structural parts 3]()

Ral90 aluminum alloy milling tool is designed for high metal removal rate. The solid tool body with optimized blade base sets a new stability standard for high-speed milling. Ral90 is specially designed for heavy-duty rough machining to cavity semi finish machining of aluminum alloy aerospace structure frame parts. The accuracy of the blade seat interface ensures the position of the cutting edge and realizes the minimum tool jump. The optimized blade groove makes the whole cutting process easier, less vibration and more reasonable chip shape. In addition, it is also designed for high pressure cooling or micro lubrication system (MQL).

Advantages: it is specially used for cavity milling of aluminum parts of aerospace frame structure; The milling cutter body with firm structure and more powerful function is designed for high cutting load and can achieve ultra-high metal removal rate; Designed to meet high safety requirements and ultra-low tool runout; Smooth cutting can reduce vibration and obtain good chip forming.

Application: specially used for cavity milling of aluminum parts of aerospace frame structure; Heavy load rough machining to semi finish machining to ensure good surface quality.

Technical features: high safety and high precision interface between cutter base and blade; Good slope milling ability; Coolant nozzle with high pressure function; The high spindle speed is certified by EN ISO 15641:2001. For example, the maximum speed of DC 40 mm milling cutter can reach 27500 rpm.

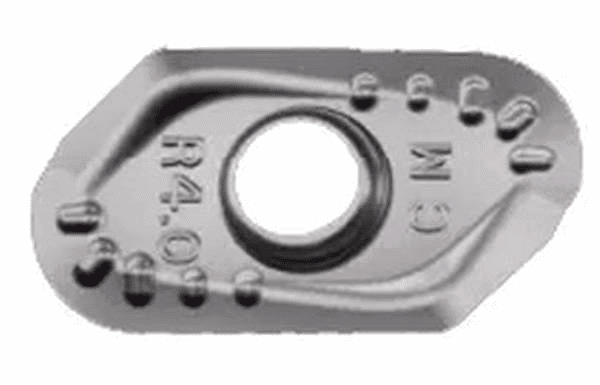

RAL90 drilling cutter

The groove is optimized for high-speed aluminum processing and can achieve unmatched high material removal rate. The edge treatment and surface treatment are optimized to achieve long tool life. The unique cutting edge design can provide stability during slope milling. The groove is specially designed for high-pressure coolant.

Super ral90

For applications requiring higher metal removal rate, the new super ral90 can reach ultra-high spindle speed. For example, the maximum speed of DC 50 mm milling cutter can reach 33000 rpm, while the ordinary ral90 has only 23500 rpm. This means a 40% increase in productivity. The stable ilock cutterbed interface can prevent the blade from small displacement and flying out of the machine tool, so as to give full play to excellent performance. The super ral90 is designed with a special interface for specific machine tool manufacturers.

Aluminum alloy milling with integral cemented carbide tool

When smaller diameter is required, integral cemented carbide tools are the perfect solution. The coromillplura end mill and the replaceable coromill 316 end mill are optimized for the groove and material of aluminum alloy, which can provide long tool life while high metal removal rate. Large chip holding groove design makes it easier for chips to discharge. In addition, the special cylindrical edge band can reduce tool vibration and minimize the possibility of edge collapse, so as to obtain excellent surface quality.

High speed drilling with integral cemented carbide tools

About 50 of more than 300 different aluminum alloy materials are widely used. Thanks to the excellent design, corodrill 860 – nm is the only high-performance bit suitable for a complete set of aluminum alloy materials. Standard product diameter range provided: 3 – 20 mm (0.118 – 0.787 inch); blade length: 3-8 times diameter; tolerance grade: it7-it8.