In metal cutting processes, the fracture behavior of materials directly affects metal cutting efficiency, surface...

CNC machining processes can produce precision parts and components with tight tolerances of ±0.025 mm...

Tungsten carbide are widely used in mechanical processing, mining drilling, military manufacturing, and other fields...

The properties of cemented carbides depend not only on the grain size of WC but...

Binders (also known as forming agents) are critical additives in the powder metallurgy process of...

Cemented carbide is a powder metallurgy product primarily composed of micron-sized tungsten carbide powder, a...

With the rapid development of modern industry, carbide?materials, used as molds and structural components, have...

The commonly used grade YT04 is characterized by its very fine average WC grain size,...

Based on the different hard phases, corrosion-resistant cemented carbides can currently be classified into three...

Tungsten carbide coatings are high-hardness protective layers formed by depositing tungsten carbide (WC) on the...

In the PCB manufacturing industry, thick copper boards have become the core substrate for power...

As an essential consumable in the field of chip packaging, capillary tips have broad development...

There are many causes of deformation in aluminum part machining, which are related to material...

Tools with positive or negative rake angle are fundamental cutting instruments whose geometric angle design...

Coating thickness technology plays a revolutionary role in modern machining, particularly for drills subjected to...

To machine stainless steel medical screws, we conducts an in-depth analysis of the issues of...

Machine tool compensation, a critical technology, is needed to correct machining errors and ensure machining...

In mechanical machining, the cutter entry method of the milling cutter directly affects the machining...

In the field of modern machinery manufacturing, CNC boring processing is an indispensable and important...

Introduction Water jet machining, also known as water jet cutting, is a versatile and innovative...

Cemented carbide fits petroleum industry,which is one of the core sectors supporting the modern energy...

Tungsten carbide roll rings (WC rolls) are high-performance rolling mill components made from tungsten carbide...

In the bearing and standard parts industry, steel balls and screws are produced using highly...

Tungsten carbide cemented carbide has good thermal conductivity, minimal hardness decrease at high temperatures, good...

The extrusion technology for tungsten carbide mixed materials has made significant advancements in terms of...

Carbide circular saw blades have been widely used in metallurgical, mechanical, and other manufacturing industries....

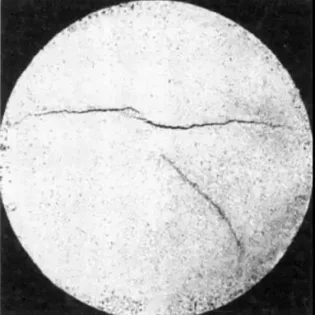

In addition to die core cracking caused by improper mold-making and wire drawing processes, the...

A mechanical seal is a device that relies on elastic components to pre-tighten the sealing...

Overview In recent years, research on coarse grain carbide grades and materials has been advancing...

Carbide?valves are widely used in various fields such as oil and gas drilling, mineral mining,...

MEETYOU CARBIDE produces a wide range of excellent tungsten carbide products (especially carbide rods, carbide...

MEC?NICA 2018 MEC?NICA MANUFACTURING EXPERIENCE ?April 24-27? 2018 Booth: G114a Expo Center Norte – SP...

Keep up-to-date

Please enter your name.

Please enter a valid email address.

Something went wrong. Please check your entries and try again.