Carbide?Valve Seat

carbide?valve seats can also be called tungsten steel petroleum valve heads. carbide?valve seats, valve assemblies, or carbide?ball valves evolved from traditional plug valves, with the opening and closing component being a sphere, achieving opening and closing purposes by rotating the sphere around the valve stem axis. The main function of carbide?valve balls in pipelines is to cut off, distribute, and change the direction of fluid flow.

Production Process of Valve Seat

carbide?valve seats are made using the carbide?cold extrusion process. Cold extrusion is a metal fine forming process with minimal or no cutting, and very low power consumption. Using cold extrusion to produce metal formed parts has unparalleled advantages in machining, especially suitable for the production of large batches of metal parts, among which carbide?valve seats are one of the applicable parts. It can also serve as a forming process for products.

There are many advantages of the carbide?cold extrusion process. Firstly, it saves raw materials. Cold extrusion uses the plastic deformation of carbides to produce parts of the required shape, thus greatly reducing machining and improving the utilization rate of raw materials. The material utilization rate of cold extrusion generally exceeds 80%, which is advantageous for the carbide?industry production.

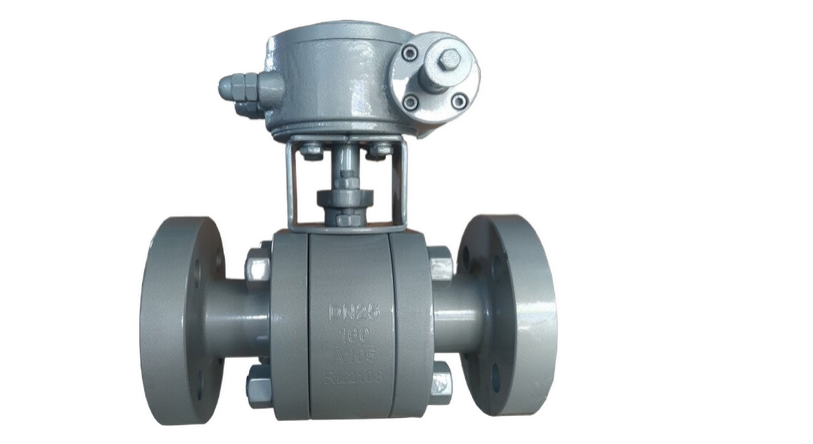

Carbide Ball Valve

The ball valve emerged in the 1950s. With the rapid development of science and technology and continuous improvement in production processes and product structures, within a short span of 40 years, it has rapidly developed into a major type of valve. In countries with developed industries in the West, the use of ball valves is increasing year by year. In China, ball valves are widely used in industries such as petroleum refining, long-distance pipelines, chemicals, papermaking, pharmaceuticals, water conservancy, electricity, municipal engineering, and steel, occupying a pivotal position in the national economy.

Carbide?ball valves are mainly used for cutting off or connecting the medium in pipelines and can also be used for fluid regulation and control. Among them, hard-sealed V-shaped carbide?ball valves have strong shear force between the V-shaped ball core and the carbide?metal seat, especially suitable for media containing fibers, tiny solid particles, etc. Multi-way carbide?ball valves can flexibly control the confluence, diversion, and flow direction switching of the medium in pipelines, while closing any one channel to connect the other two channels. Such valves should generally be installed horizontally in pipelines. Classification of carbide?ball valves: pneumatic carbide?ball valves, electric carbide?ball valves, manual carbide?ball valves.

It has a 90-degree rotational action, with the closure body being a sphere with a circular through-hole or passage along its axis. carbide?ball valves are mainly used in pipelines for cutting off, distributing, and changing the flow direction of the medium. They can be tightly closed with just a 90-degree rotation and a small turning torque. carbide?ball valves are most suitable for use as on-off and cut-off valves, especially V-shaped carbide?ball valves.They are also widely used in vacuum systems.

Features of carbide ball valves

Carbide?ball valves not only have simple structure and good sealing performance but also within a certain nominal diameter range, they are small in size, lightweight, consume less material, have small installation dimensions, and require low driving torque. They are easy to operate and achieve quick opening and closing, making them one of the fastest-growing valve types in recent decades. carbide?ball valves evolved from plug valves, with their closing member being a sphere, which rotates 90° around the valve stem axis to achieve opening and closing. carbide?ball valves are mainly used in pipelines for cutting off, distributing, and changing the flow direction of the medium, and carbide?ball valves with V-shaped openings also have good flow regulation functions.

Applications of Several Common Carbide Ball Valves

Especially in industrialized countries such as the United States, Japan, Germany, France, Italy, Spain, and the United Kingdom, carbide?ball valves are widely used, with the variety and quantity of use still expanding. They are moving towards high temperature, high pressure, large diameter, high sealing, long life, excellent regulatory performance, and multifunctional direction. Their reliability and other performance indicators have reached a high level, and they have partially replaced gate valves, globe valves, and throttle valves. With the technological progress of carbide?ball valves, they will have broader applications in the foreseeable future, especially in oil and natural gas pipelines, refining and cracking units, and nuclear industry. In addition, in medium and large-caliber, medium and low-pressure fields in other industries, carbide?ball valves will also become one of the dominant types of valves.

carbide?ball valves are suitable for double-position adjustment, high sealing performance requirements, fast opening and closing (1/4 turn), high pressure drop, small operating torque, low flow resistance, and erosion in pipeline systems or vaporization.

In pipelines with certain corrosive media.

In low-temperature devices or high-temperature and high-pressure pipeline systems.

Full-bore welded carbide?ball valves can be used in petroleum pipelines and natural gas pipelines buried underground.

Specially designed V-shaped carbide?ball valves also have certain adjustment functions.

Assembly of carbide?Ball Valves and Valve Seats

1.Ball Processing

The core component of a ball valve is the sphere, so ball processing is the most critical part of ball valve manufacturing. Common ball processing materials include copper, iron, stainless steel, etc., and processing techniques include forging, casting, etc. The production of ball valve balls requires multiple processes such as rough machining, finishing, surface treatment, and carbidespraying to meet production requirements.

2.Valve Body Casting

The valve body of a ball valve is usually made of cast steel or forged steel. Casting methods include sand casting, pneumatic mold casting, etc. Before casting, mold design, casting process, and procedures need to be formulated, and strict material selection and quality inspection are required to ensure the reliability and durability of the valve body.

3.Stem Processing

The stem is the connecting part between the ball and the actuator of the ball valve, so the processing and production of the stem are very important. Chromium-molybdenum alloy steel is commonly used for stem materials, and processing techniques include turning, grinding, etc. During stem processing, attention should be paid to accuracy and smoothness, and heat treatment and surface treatment should be carried out to improve corrosion resistance.

4.Seal Installation

The seals of a ball valve include valve seats, sealing gaskets, etc., which must be installed in the appropriate positions to ensure the sealing performance of the ball valve. When installing seals, correct assembly and installation operations should be performed according to the structure and requirements of the ball valve.

5.Testing

After the manufacturing of the ball valve is completed, testing is required to verify its good performance and reliability. Testing includes hydrostatic testing, airtightness testing, pressure resistance testing, etc. Only ball valves that pass the test can be put into use.

In summary, the manufacturing process of ball valves includes multiple steps such as ball processing, valve body casting, stem processing, seal installation, and testing. Each step requires strict manufacturing standards and control to ensure the quality and performance of ball valves.

Conclusion

High-precision customized production and processing of carbide valve seats, valve assemblies, and carbide ball valves are used in oil drilling, deep-sea drilling pump valve balls, and seats, which are critical supporting parts in oil pump equipment. The use of valve seats and petroleum valve heads is mainly for petroleum equipment production purposes.Meteou specializes in the technical and professional production of carbide products, providing customized carbide valve seats, petroleum valve balls, petroleum valve assemblies, and other series of wear-resistant and corrosion-resistant carbide parts tungsten steel fittings that meet the requirements of petroleum equipment usage.