What is carbide?

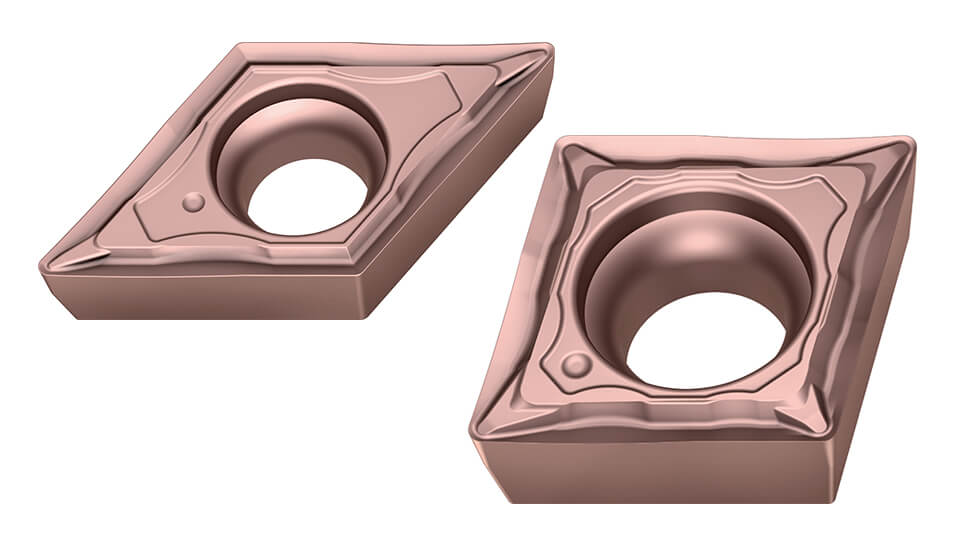

carbide?is an alloy material made through powder metallurgy process, consisting of hard compounds of refractory metals and a binding metal. carbides exhibit excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance, and corrosion resistance. Particularly noteworthy are their high hardness and wear resistance, which remain largely unchanged even at temperatures as high as 500°C and maintain significant hardness at 1000°C.

carbides are widely used as cutting tool materials, including turning tools, milling cutters, planers, drill bits, boring tools, etc. They are employed for machining a variety of materials, including cast iron, non-ferrous metals, plastics, synthetic fibers, graphite, glass, stone, and common steel. Additionally, carbides can be utilized for cutting challenging materials like heat-resistant steel, stainless steel, high manganese steel, and tool steel.

?

What is metal ceramic?

Metal ceramic is a composite material composed of ceramic and metal. It is defined by the ASTM (American Society for Testing and Materials) committee as a heterogeneous composite material consisting of metal or alloy and one or more ceramic phases, where the latter typically constitutes 15% to 85% by volume. Importantly, at the preparation temperature, there is minimal solubility between the metal and ceramic phases. In a narrow sense, metal ceramics refer to a category of materials within composite materials where both metal and ceramic phases have interfaces in three-dimensional space.

Composition of metal ceramic

Metal ceramics are created by adding metal powder to the clay used in ceramic production, allowing the ceramic to withstand high temperatures without becoming easily breakable. Metal matrix metal ceramics, also known as dispersion-strengthened materials, are produced by adding oxide fine powders to a metal matrix. Examples include sintered alumina (aluminum-alumina), sintered beryllium (beryllium-beryllium oxide), TD nickel (nickel-thorium oxide), and others. These are composite materials composed of one or more ceramic phases and metal or alloy phases.

In a broader sense, metal ceramics also encompass refractory compound alloys, carbides, and metal-bonded diamond tool materials. The ceramic phase in metal ceramics consists of oxides or refractory compounds with high melting points and high hardness, while the metal phase primarily consists of transition elements (iron, cobalt, nickel, chromium, tungsten, molybdenum, etc.) and their alloys.

Classification of metal ceramic

Metal ceramics are classified into two categories based on the percentage of each component phase: those with ceramics as the matrix and those with metals as the matrix. Metal matrix metal ceramics typically exhibit high temperature strength, low density, ease of processing, corrosion resistance, and good thermal conductivity. Therefore, they are commonly used in the manufacturing of structural components for aircraft and missiles, engine pistons, chemical machinery parts, and more.

Ceramic matrix metal ceramics can be further subdivided into several types:

Oxide-based metal ceramics

Used for missile nozzle liners, crucibles for melting metals, and metal cutting tools.

Carbide-based metal ceramics

Utilized in the production of cutting tools, high-temperature bearings, sealing rings, wire drawing dies, and turbine blades.

Nitride-based metal ceramics

Less commonly applied.

Boride-based metal ceramics

Less commonly applied.

Silicide-based metal ceramics

Using silicides as the matrix, combined with partial or trace amounts of metal materials. Among them, siliconized molybdenum metal ceramics find wide applications in industry.

The main difference between the two materials

Material distinction

WC (tungsten carbide) carbide?blades are produced using advanced metal powders such as tungsten-cobalt, tungsten-samarium, tungsten-titanium, tungsten carbide, etc., as raw materials, and they undergo high-temperature and high-pressure sintering to achieve their final form. On the other hand, ceramic blades use raw materials like aluminum oxide, zirconium oxide, etc., and are formed through high-temperature sintering treatment to create a new type of material.

Cutting performance

?????

Ceramic blades typically exhibit higher hardness than WC (tungsten carbide) carbide?blades, reaching levels of 1800-2200HV, while the hardness of WC carbide?blades generally falls between 1600-2000HV.

Cutting Performance

In comparison to WC carbide?blades, ceramic blades offer higher precision and smoother cutting surfaces. Achieving high-precision machining results often requires only a single cut with ceramic blades. WC carbide?blades perform better in cutting softer materials, and they often have faster cutting speeds.

Cutting Lifespan

Ceramic blades have better wear resistance, resulting in a longer lifespan. WC carbide?blades are typically more suitable for mass production processing of workpieces.

Physical performance

?????

Ceramic blades typically exhibit higher hardness than WC (tungsten carbide) carbide?blades, reaching levels of 1800-2200HV, while the hardness of WC carbide?blades generally falls between 1600-2000HV.

Cutting Performance

In comparison to WC carbide?blades, ceramic blades offer higher precision and smoother cutting surfaces. Achieving high-precision machining results often requires only a single cut with ceramic blades. WC carbide?blades perform better in cutting softer materials, and they often have faster cutting speeds.

Cutting Lifespan

Ceramic blades have better wear resistance, resulting in a longer lifespan. WC carbide?blades are typically more suitable for mass production processing of workpieces.

The differences between the two materials

Machining Performance

Ceramic blades are relatively brittle and prone to fracture under external impact. In contrast, the manufacturing process for WC (tungsten carbide) carbide?blades is simple, and they are easy to use and maintain.

Price and Applicability

Ceramic blades are relatively more expensive but are suitable for high-precision cutting processes, such as in the fields of microelectronics and semiconductors. On the other hand, WC carbide?blades are more cost-effective and are suitable for large-scale machining applications.