Twist drills and deep hole gun drills have always been a common choice in the deep hole processing industry. We can make these two tools process the commonly used q235 steel, #45 steel and aluminum, to explore the difference of the surface quality of the machining holes produced by the two tools, and the variation of the surface quality of the two tools under different hardness materials.

How twist drills and gun drills work

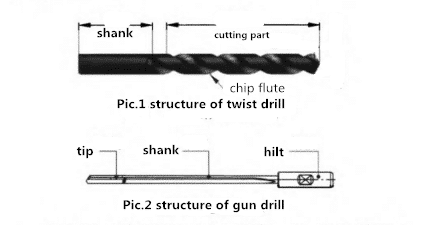

As shown in the pic 2, the twist drill is generally divided into a straight shank type and a taper shank type. Its working principle is that the drill bit rotates at a high speed under the spindle drive, and the workpiece is continuously fed downward, and the chips are removed from the spiral groove to obtain the desired hole. .

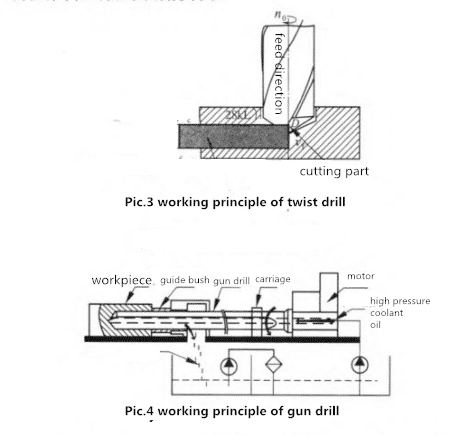

During the gun drilling process, the pump outputs high-pressure coolant through the internal hole of the drill pipe into the front cutting area. While cooling and lubricating the tool, the chips are discharged from the high-pressure liquid through the V-groove of the drill pipe to the fuel tank. It can be fixed and then cut by rotating the workpiece, which gives the hole a higher precision.

The equipment used for twist drills is generally bench drill and radial drill machine, and can also be done on ordinary milling machines or CNC machines. Most of the gun drills use CNC deep hole machining machines, which require high pressure oil supply and filtration systems.

Processing experiment comparison

1.Cutting speed

The cutting speed can be measured by linear velocity and angular velocity, respectively. The relationship between angular velocity n (r/min) and linear velocity Vc (mm/min) is:

Vc=ndπ/100. d is the effective diameter of the tool

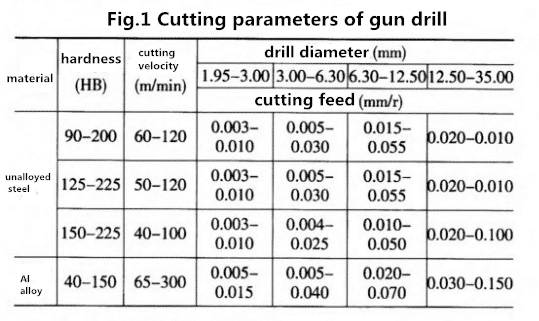

The cutting speeds of different tool materials are different. The following fig.1 is the cutting speed of the gun drill.

2. Feed rate Vf

Vf can be expressed in terms of the vertical depth of the tool cut into the workpiece per minute, or by the distance the tool cuts per revolution. For the gun drill feed amount, refer to Table 1. Usually, f=0.01~0.032mm/r is selected. The gun drill feed rate is lower than the twist drill.

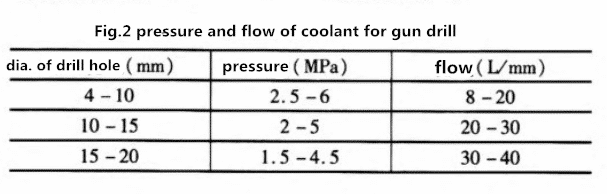

3.Coolant oil pressure

The choice of oil pressure P (kg/cm2) is related to the smooth discharge of cooling and chips, and has a great influence on the surface quality of the product. The relationship between cutting pressure and flow rate of gun drill is shown in Table 2.

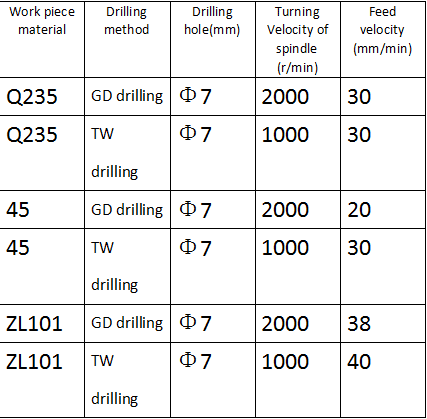

Table 3 shows the experimental conditions of gun drill on #45 steel, Q235 steel and aluminum alloy grade ZL101.

Experimental data

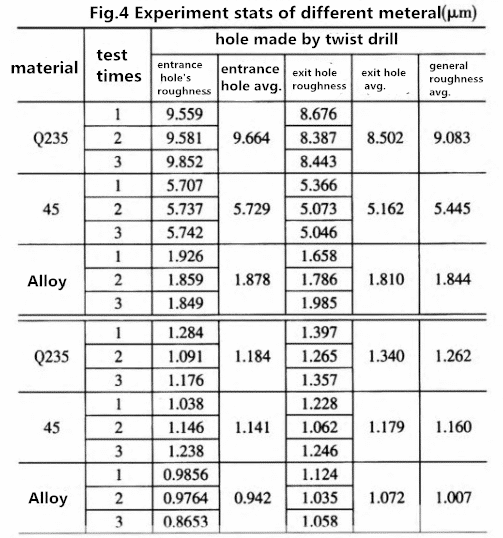

After many experiments, the surface roughness values ??of the inlet and outlet of the three materials are shown in Table 4.

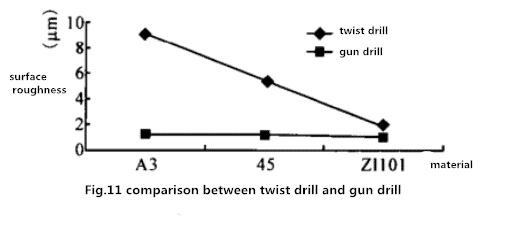

As can be seen from the above table, the surface roughness of the machined hole of the gun drill is lower than that of the twist drill. Both the gun drill and the twist drill can machine holes with a small roughness on the aluminum. It is worth noting that the chips produced by the twist drill aluminum and Q235 steel are spiral. The gun drill is a straight edge cutter with no spiral flutes, so the chips it produces are mostly sheet-like. In this way, the chips are short, the chip removal is easy, the knife bar is not wound, and the hole wall of the part is not scratched. Moreover, as can be seen from the above table, when processing these three materials, the surface roughness of the gun drilling is close, and the roughness of the hole processed by the twist drill is relatively far. Only when processing in non-ferrous metals, the processing effect of twist drills is closer to that of gun drills, and the physical properties of due to non-ferrous metals are relatively low. In summary, the processing quality of gun drills should be superior to twist drills.

So why is this happening? There are 2 reasons below:

1. Twist drills produce relatively large torque during processing. This can cause the axis skew to cause centering difficulties. At this time, the twist of the twist drill can cause burrs. The gun drill has a drill sleeve guide for precise positioning. Therefore, the processed holes have substantially no burrs.

2. Twist drill cutting edge is longer, and the spiral groove will also increase the difficulty of chip removal. The spiral chip friction scratches the hole wall, which is also the cause of the increase in roughness. The gun drill uses hydraulic chip evacuation to lubricate and remove the cutting heat. Protects the surface of the tool and workpiece.