A notable property of wood is its anisotropy, which leads to distinctions between longitudinal, transverse, end-wise, and transitional cutting during the machining of solid wood. Wood-based panels and wood composite materials are made from wood monomers, such as veneers, shavings, or fibers, which are combined with adhesives under specific temperatures and pressures to form a composite material. The properties of these materials are determined by the wood monomers, their arrangement, and the characteristics of the adhesive. The machinability also varies due to the structure and the proportion and nature of the additives. For example, medium-density fiberboard (MDF) is nearly isotropic, with almost equal cutting resistance across the board; particleboard, due to uneven density distribution and differences between the surface and internal structure, has significant variations in cutting resistance; and blockboard, composed of glued solid wood strips, has differences in grain direction between the strips, thus exhibiting both similar and different properties compared to solid wood during machining.

Selection of Wood Milling Cutter Structure

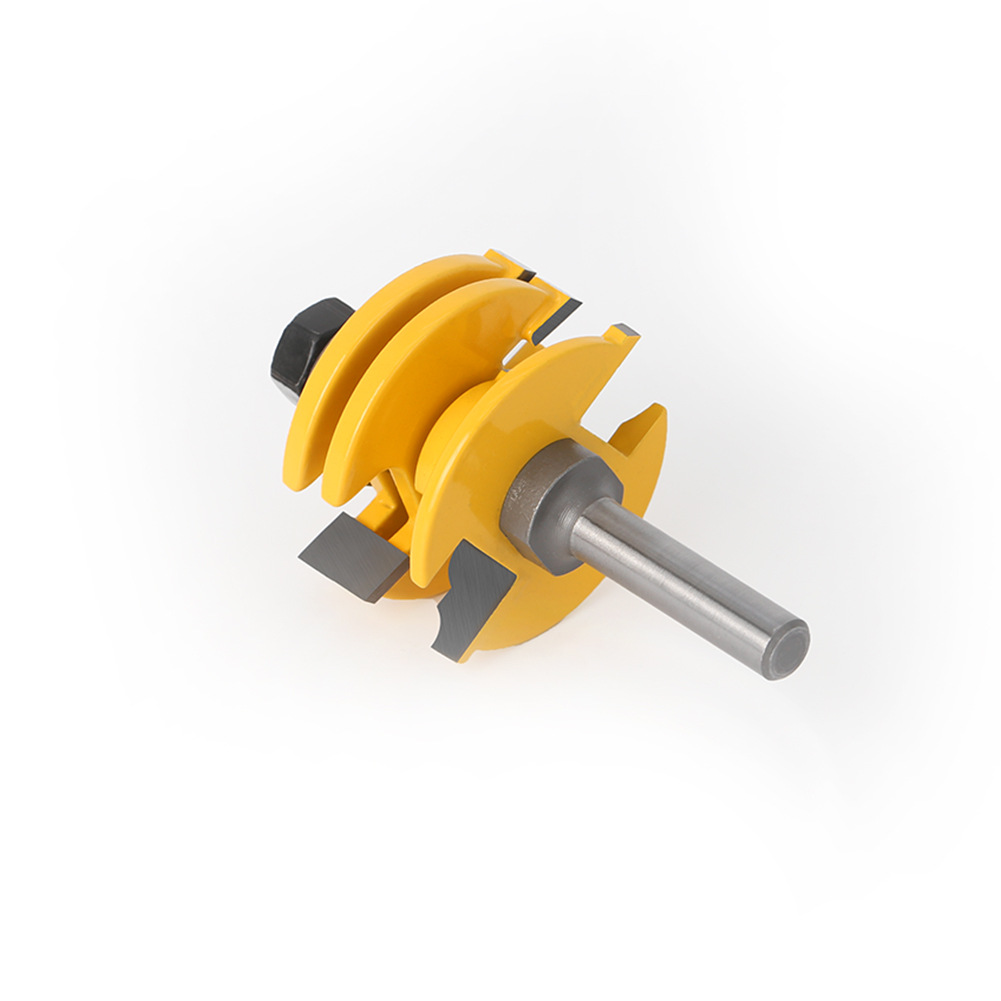

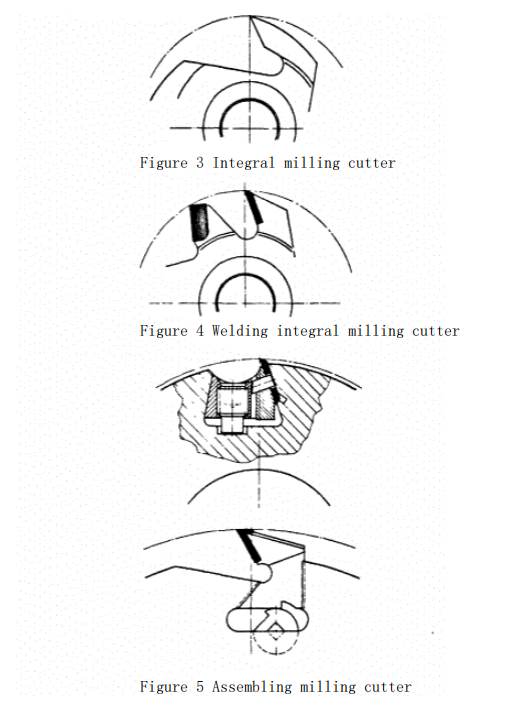

Based on the nature and requirements of the cutting object, a comprehensive consideration from both technical and economic perspectives is necessary to select the appropriate milling cutter structure. Options include solid wood milling cutters (Figure 3), welded solid milling cutters (Figure 4), assembled milling cutters (Figure 5), and combined milling cutters.

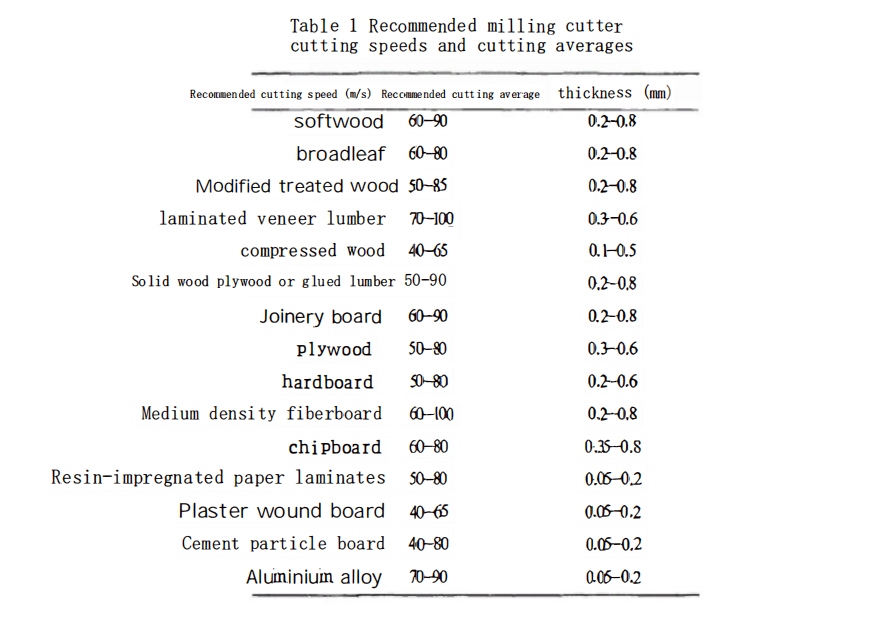

Selection of Milling Cutter Cutting Parameters (Table 1)

The cutting parameters of a milling cutter include the cutting speed of the cutter, the feed rate of the workpiece, and the milling depth. The cutting speed of the milling cutter depends on the cutter’s rotational speed and diameter. The feed rate of the workpiece depends on the requirements for the surface quality of the machined surface. The surface roughness of the workpiece is largely determined by the feed per tooth during the cutting process. If the feed per tooth is too large, the machined surface will be too rough; if the feed per tooth is too small, the machined surface may exhibit burn marks.

Depending on the different milling objects and surface quality requirements, the recommended feed per tooth for wood products processing is generally as follows: for rough machining, Uz = 0.8~1.5mm; for finish machining, Uz = 0.4~0.8mm. If the feed per tooth is within 0.1~0.3mm, there is a risk of the machined surface being burned. For all wood products, the common feed per tooth is Uz = 0.3~1.5mm. For a smooth surface, the feed per tooth Uz = 0.3~0.8mm; for a medium surface, Uz = 0.8~2.5mm; for a rough surface or when surface quality is not a concern, the feed per tooth Uz = 2.5-5.0mm.

Stability of Milling Cutter Operation

The stability of the milling cutter during operation is the basis for ensuring machining accuracy and surface quality. This includes two aspects: first, the vibration of the milling cutter during cutting due to external force excitation; and second, the deformation of the milling cutter under the action of external forces. Vibration is related to the structure of the milling cutter, the method of installation, and unbalanced mass. When the frequency of the external excitation force is close to the natural frequency of the milling cutter,the wood milling cutter will resonate, and the amplitude will increase significantly. A considerable portion of the milling cutters used for wood cutting are installed in a cantilevered manner. In this case, the static force due to the cutter’s own weight and the dynamic force generated by high-speed rotation act in combination on the cutter shaft. Under the action of this force, the cutter shaft will deform, producing a certain degree of deflection.

Since tool vibration and cutter shaft deformation will ultimately severely affect the surface quality of the workpiece, it is necessary to limit the unbalanced mass of the milling cutter and to avoid the cutter’s rotational frequency from matching its natural frequency. Additionally, for cantilevered cutter shafts, it is essential to limit the mass of the wood milling cutter, which means restricting the length and diameter of the cutter.

Safety of Milling Cutter Processing

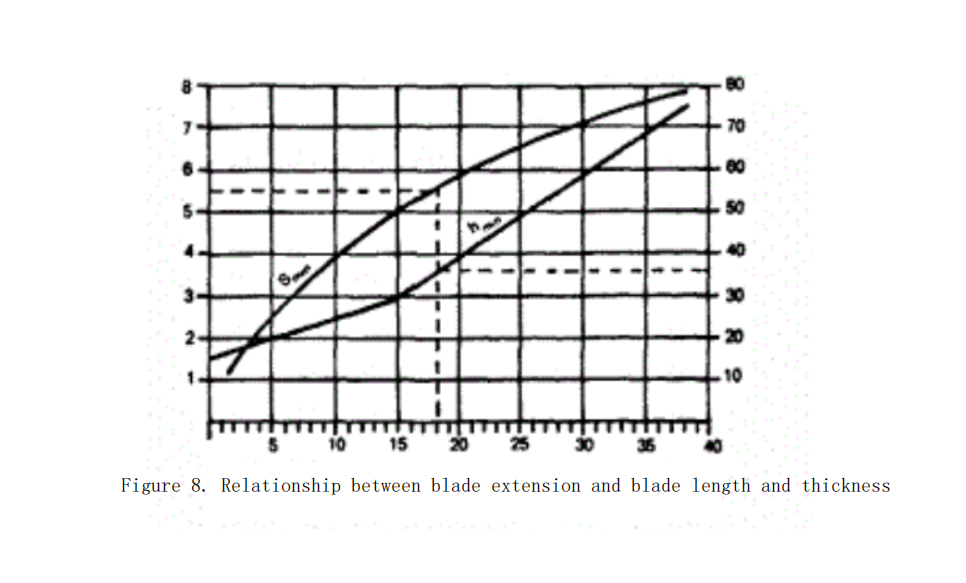

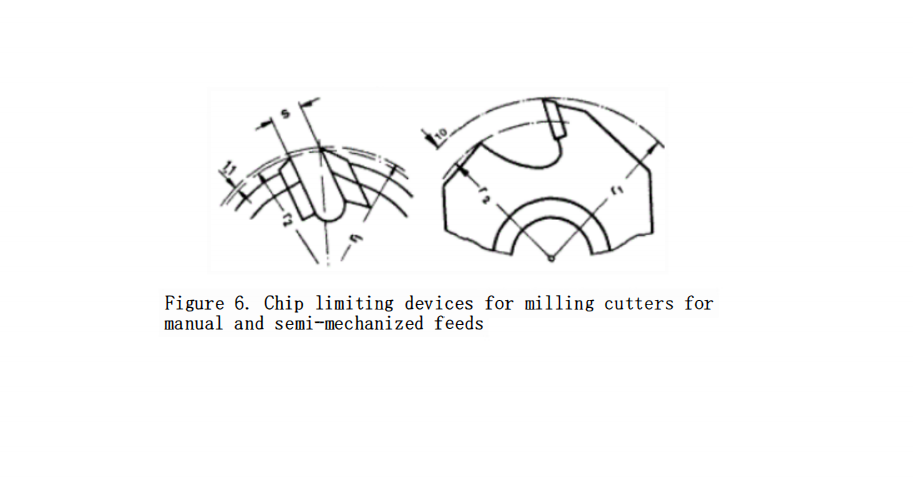

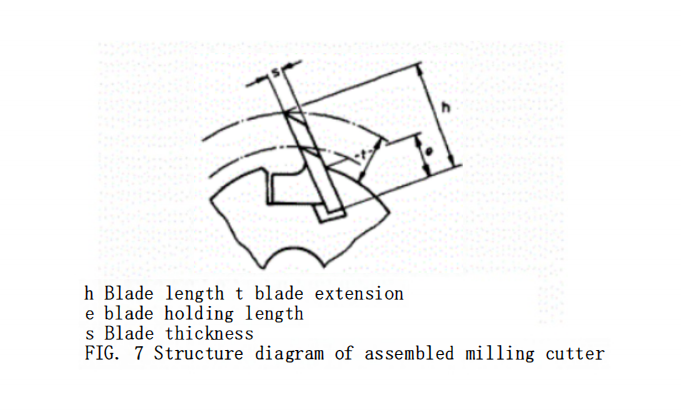

The safety of wood milling cutter processing includes restrictions on the rotational speed of the milling cutter, limitations on chip thickness (Figure 6,7), restrictions on the profile height of shaped wood milling cutters, and limitations on the thickness and projection length of the blades for assembled wood milling cutters.

The characteristic of wood milling processing is high speed, with the rotational speed of the milling cutter often exceeding 3000rpm. High-speed cutting brings a series of safety issues. When the spindle speed of the milling machine reaches 9000rpm, the use of assembled milling cutters should be prohibited except for shank cutters with a diameter less than 16mm; strict non-destructive testing of the welds on welded solid milling cutters should also be conducted. When the milling cutter leaves the factory, the manufacturer has marked the maximum allowable speed on the body of the cutter, and the user must strictly adhere to this regulation; under no circumstances should the maximum allowable speed be exceeded.

The limitation on chip thickness is a necessary measure to prevent severe overload of the milling cutter due to excessive feed. According to the regulations of the German Association of Woodworking Machinery and Tool Manufacturers, for manually fed machines, the thickness of the milling chips should not exceed 1.1mm, and there are certain requirements for the width of the chip flute for different cutting milling cutters. For semi-mechanically fed machines, the maximum thickness of the milling chips should not exceed 10mm. For fully automatic, mechanically fed machines, there are no restrictions on the thickness of the milling chips and the chip flute, but general safety regulations must be observed.

For shaped milling cutters, the profile height of the shaping contour is closely related to the clamping method of the cutter, the thickness of the workpiece being cut, and the diameter of the cutter. Once the thickness of the workpiece, the diameter of the cutter, and the diameter of the center hole are determined, the profile height of the cutter reflects the cutter’s own strength and rigidity, as well as its ability to withstand cutting resistance. Therefore, there must be limitations on the profile height to ensure safety when using the cutter. On multi-axis milling machines (four-sided planers) and double-end wood milling machines or mortising machines, the spindle shaft diameter must not be less than 30mm. Moreover, due to the space limitation for installing the cutter, the height of the shaped contour cannot be too high.

When designing the body of an assembled wood milling cutter, the issue of blade clamping must be considered. Whether it is a cylindrical or disc-shaped body, the blade clamping form must ensure that it can provide a sufficiently large clamping force to counteract the rotational centrifugal force. For the integral blades or inserted welded blades clamped radially by the pressure plate, there must be a minimum limit on the projection length of the blade, as well as the thickness and length of the blade. When the thickness and length of the blade are less than this minimum limit, it means that the use of the wood milling cutter should be strictly prohibited. Otherwise, there will be safety risks. Figure 8 shows the projection length and the thickness and length of the blade for assembled wood milling cutters.