In this study, two different high-temperature performance matrix body?materials were prepared by adding trace amounts of TaC (NbC) carbide to the carbide?matrix body. The high-temperature hardness and high-temperature fracture toughness of the two carbides were tested using a high-temperature Vickers hardness tester. Whole carbide?end mills?with the same geometric parameters were prepared based on the two matrix body?materials, and titanium alloy TC4 milling?tests were carried out. By analyzing the tool life and wear patterns, the impact of TaC (NbC) on the wear performance of carbide?milling?tools in high-speed milling was studied.

Experimental conditions and testing methods

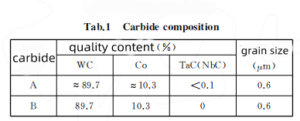

Two different WC-Co-based carbide?materials with different compositions, named A and B, were prepared for the experiment. Trace amounts of TaC (NbC) carbide were added to material A, with a mass fraction of less than 0.1%. The compositions of the two carbides are shown in Table 1.

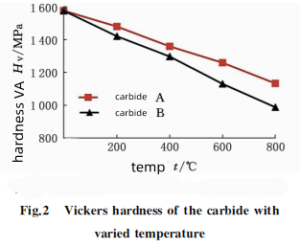

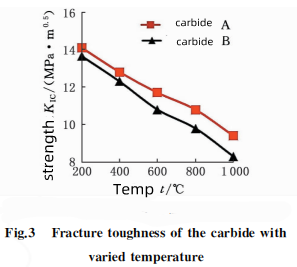

The high-temperature hardness and high-temperature fracture toughness of materials A and B at different temperatures are shown in Figures 2 and 3, respectively.

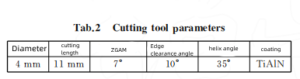

Based on the two carbide?materials A and B, four-flute flat end mills?A and B with the same geometric parameters were prepared accordingly. The specifications and parameters of the tools are shown in Table 2.

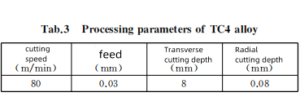

The workpiece material for the milling?test is annealed titanium alloy TC4, with a material hardness of 28.2 HRC. The milling?test was performed on a Mazak Nexus 430A-II vertical machining center, and the machining parameters are shown in Table 3.

Experimental results and discussion

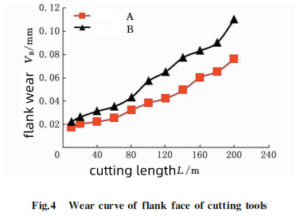

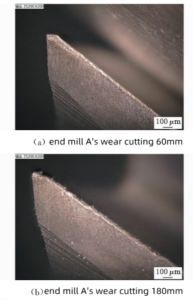

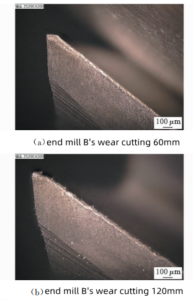

Under the same milling?conditions, the flank wear curves of end mills?A and B in the machining of titanium alloy TC4 are shown in Figure 4. Figure 5 shows the flank wear morphologies of the two end mills.

From Figures 4 and 5, it can be seen that when the milling?distance is less than 60m, both types of carbide?end mills?are in the normal wear stage, and the amount of wear on the tool’s back surface increases slowly. This stage is mainly in the early stage of milling, where the tool coating has good wear resistance and insulation, which effectively protects the tool matrix body?during this stage.

However, due to the very high milling?temperature of titanium alloy, as milling?continues, the coating on the tool edge is worn off, exposing the tool matrix body. The tool edge directly bears severe thermal and mechanical shock. As the matrix body?of end mills?A is added with trace alloy carbide TaC (NbC), its high-temperature hardness and high-temperature fracture toughness are higher than that of end mills?B. Therefore, end mills?A has more advantages than end mills?B in terms of the amount of wear on the back surface of the tool.

Analysis of end mills failure

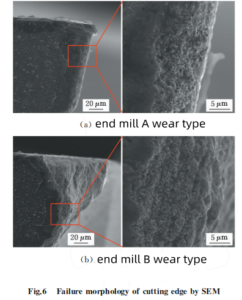

After milling?200m using vertical milling cutters A and B, the worn positions of the tool tips were analyzed using a scanning electron microscope. The tip wear morphologies of the two vertical milling cutters are shown in Figure 6.

From Figure 6, it can be seen that the addition of trace amounts of alloy carbide TaC(NbC) in vertical milling cutter A has improved the high-temperature fracture toughness of the WC-Co carbide, suppressed the formation and propagation of cracks within the tool matrix body, and extended the tool life. On the other hand, the high-temperature fracture toughness of vertical milling cutter B is lower than that of A, and when the milling?edge is subjected to severe thermal shock and mechanical loads, cracks are easily formed and continuously expanded, causing the tool matrix body?material at the milling?edge to break and ultimately resulting in tool failure.

???????

Under the same main elements, the carbide?material A with trace amounts of alloy carbide TaC(NbC) has higher high-temperature hardness and fracture toughness than the carbide?material B without adding trace amounts of alloy carbide TaC(NbC). At 800℃, the high-temperature hardness is increased by approximately 14.5%, and the high-temperature fracture toughness is increased by approximately 10.2%.

When milling?titanium alloy TC4 under the same conditions, the tool with added trace amounts of alloy carbide TaC(NbC) has better wear resistance. When the milling?distance is 200m, the amount of wear on the back surface of vertical milling cutter A is 0.076mm, while the amount of wear on the back surface of vertical milling cutter B is 0.13mm.

The high-temperature fracture toughness of the carbide?material A with TaC(NbC) added is better. Under the same milling?conditions, the milling?edge retention of vertical milling cutter A is better, and there are significantly fewer cracks in the worn failure area compared to vertical milling cutter B.