Pre-Drilling Entry

Characteristics: One of the safest cutter entry methods

Applicable Scenarios: Machining materials prone to chip accumulation

Operation Method: Pre-drill a hole in the workpiece (5%-10% larger than the end mill diameter), then enter the milling cutter through the hole.

Advantages:

Prevents premature tool wear

Ensures smooth chip evacuation, reducing the risk of chip accumulation and tool breakage

Particularly suitable for machining materials like aluminum and copper that tend to stick to the tool

Disadvantages:

Additional Process: Requires an extra pre-drilling step, increasing machining time and cost.

Precision Limitations: The diameter and position of the pre-drilled hole must be precise; otherwise, it may affect subsequent milling accuracy.

Unsuitable for Thin-Walled Workpieces: Pre-drilling may cause deformation or damage to thin-walled workpieces.

Material Waste: Pre-drilling removes some material, which may not be suitable for scenarios requiring high material utilization.

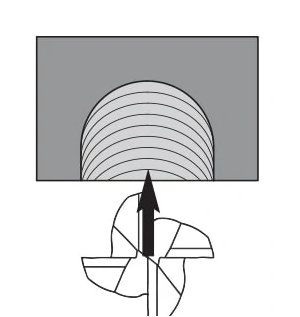

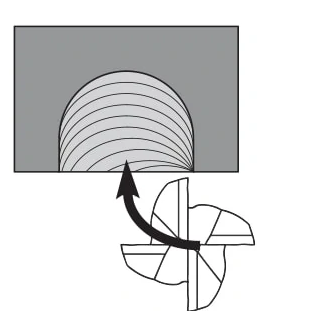

Helical Entry

Characteristics: Safe and efficient

Applicable Scenarios: High-precision machining, such as aerospace and medical device manufacturing

Operation Method: Use a corner-radius end mill to enter the workpiece gradually along a helical path. During programming, the helical diameter should be 110%-120% of the cutting insert diameter.

Advantages:

Reduces tool wear and breakage risk

Provides excellent surface finish

Suitable for deep cavity machining and complex contours

Disadvantages:

Complex Programming: Requires precise CNC programming, demanding higher technical skills from operators.

Longer Machining Time: The helical path is longer, potentially increasing machining time.

High Tool Cost: Requires high-quality corner-radius end mills, increasing tool costs.

Unsuitable for Shallow Grooves: In shallow groove machining, the advantages of helical entry are less pronounced and may reduce efficiency.

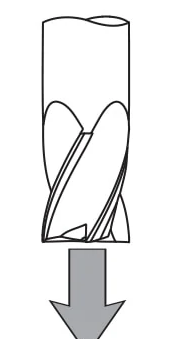

Ramp Entry

Characteristics: Efficient with minimal impact on workpiece deformation

Applicable Scenarios: Contour machining, pocket machining

Operation Method: The milling cutter enters the workpiece at an angle (usually 1°-10°) and gradually increases the cutting depth.

Advantages:

Reduces axial force, minimizing workpiece deformation risk

Improves dimensional accuracy

Suitable for machining high-strength materials

Disadvantages:

Complex Tool Forces: Ramp cutter entry applies multiple torsional forces on the tool, potentially leading to fatigue damage.

Chip Evacuation Issues: Poor tool design may result in poor chip evacuation, affecting machining quality.

Angle Selection Difficulty: Requires precise angle selection based on material properties; otherwise, machining effectiveness may be compromised.

Unsuitable for Brittle Materials: Brittle materials may develop cracks or chipping during ramp entry.

Circular Entry

Characteristics: Smooth cutter entry, reducing impact

Applicable Scenarios: Mold manufacturing, 3D contour machining

Operation Method: The milling cutter enters the workpiece from the side along a curved path, gradually increasing the load and decreasing it upon exit.

Advantages:

Avoids impact loading, extending tool life

Improves surface finish and machining efficiency

Suitable for complex surface machining

Disadvantages:

Complex Programming: Requires precise curved path programming, demanding higher CNC system capabilities.

Long Tool Path: The circular entry path is longer, potentially increasing machining time.

Unsuitable for Narrow Grooves: Circular entry may not be feasible for narrow groove machining, limiting its application.

Concentrated Tool Wear: Circular cutter entry may cause concentrated wear on a specific part of the tool, affecting its lifespan.

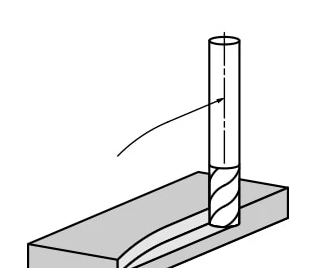

Plunge Entry

Characteristics: Simple but high-risk

Applicable Scenarios: Machining with center-cutting tools

Operation Method: The milling cutter enters the workpiece vertically from the top.

Advantages:

Simple operation, suitable for quick machining

Applicable to center-cutting tools like drills

Disadvantages:

High Tool Breakage Risk: Plunge entry is prone to tool breakage, especially when machining hard materials.

Poor Chip Evacuation: Chip evacuation is difficult, leading to chip accumulation and affecting machining quality.

High Workpiece Damage Risk: Plunge cutter entry may cause surface damage or deformation of the workpiece.

Unsuitable for Deep Grooves: In deep groove machining, plunge entry poses higher risks and is more likely to damage the tool.

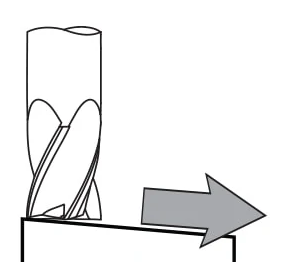

Straight-Line Side Entry

Characteristics: Simple and direct, but causes significant tool wear

Applicable Scenarios: Simple cutting operations

Operation Method: The milling cutter enters the workpiece from the side and gradually increases the cutting depth.

Advantages:

Simple operation, suitable for low-precision machining

Effectively resolves tool entry difficulties

Disadvantages:

Severe Tool Wear: Straight-line side entry causes significant tool wear, especially when machining high-strength materials.

Feed Rate Limitation: The feed rate must be reduced by 50% during cutter entry, affecting machining efficiency.

Chip Evacuation Issues: Poor chip evacuation may lead to tool breakage or workpiece damage.

Unsuitable for Complex Contours: Straight-line side entry is less effective for complex contour machining, limiting its application.

Roll-In Entry

Characteristics: Ensures consistent chip thickness

Applicable Scenarios: Grooving, contour machining

Operation Method: The milling cutter enters the workpiece in a rolling manner, gradually increasing the cutting depth.

Advantages:

Maintains consistent chip thickness, improving surface finish

Reduces tool wear and heat generation

Suitable for high-speed machining

Disadvantages:

Feed Rate Limitation: The feed rate must be reduced by 50% during entry, affecting machining efficiency.

Complex Programming: Requires precise CNC programming, demanding higher technical skills from operators.

High Tool Cost: Requires high-quality rolling tools, increasing tool costs.

Unsuitable for Shallow Grooves: In shallow groove machining, the advantages of roll-in entry are less pronounced and may reduce efficiency.

Summary

Each milling cutter entry method has its unique advantages and disadvantages. In practical machining, the appropriate entry method should be selected based on workpiece material, machining requirements, and tool characteristics. By effectively utilizing these methods, machining efficiency can be maximized, tool life extended, and workpiece quality ensured. Additionally, addressing the disadvantages of each method through measures such as optimized programming and adjusted cutting parameters can further enhance machining results