Properties

Polycrystalline cbn is a highly durable material, similar to diamond in its composition and properties. It can process a wide variety of materials, from steel and cast iron to alloys of high strength and hardness. In addition, PCBN can resist oxidation at high temperatures. These properties make it ideal for cutting tools.

PCBN is also suitable for friction stir welding. These processes require a tool material with high temperature strength and toughness. They also require high chemical and thermal stability. Polycrystalline cubic boron nitride is one of the few materials that meet these requirements.?Its chemical stability and high temperature strength are essential for successful welding.

The mechanical properties of sintered cBN composites are presented in Table 3. The strength of composites made from different TiAl particle sizes varied according to the ball milling method used. The most effective composition was obtained when the TiAl particles were five mm in diameter. The average TiAl particle size is approximately 15 mm.

c-BN is also an excellent candidate for hard protective coatings. Compared to diamond, it is chemically inert in oxygen. It also has high thermal conductivity and electrical resistivity. It can also be used to coat optical elements, such as windows. Further, it is used in the manufacturing of grinding wheels.

Cast iron is an example of an iron alloy that contains carbon, silicon, nickel, and manganese. It varies in elongation, hardness, and machinability. In contrast, PCBN cutting materials produce high-quality surfaces throughout their service life. In addition, they can withstand high temperatures.

cBN can be reacted with other materials such as AlN or TiB 2 to form a three-dimensional network matrix. This three-dimensional network structure helps improve the bonding between the cBN grains and the binder. These properties are important for high-performance PCB designs.

Besides being conductive, PCBs also have other important properties. The dielectric volume resistance is important for maintaining isolation between the layers. However, it may cause significant signal loss, especially for analog signals. This signal loss increases with frequency. Also, temperature plays an important role in determining whether the PCB material undergoes a reversible change from soft to hard or permanent decomposition. It is best to avoid exceeding the solder temperature to avoid permanent decomposition.

The properties of PCB materials vary widely. The most common are normal-speed materials, which fall in the FR-4 family. Their low-loss properties make them ideal for digital/analog applications. The other category is called medium-speed materials, and it contains a lower dielectric loss than the normal-speed material. The medium-speed materials are good for applications where higher-frequency transmission is necessary.

Application

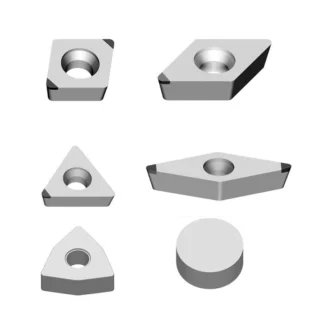

When using PCBN material in cutting tools, it is important to select the right application for the tool. While many of the materials have their advantages, some have a disadvantage. Here are a few tips for selecting the right PCBN tool. Ensure that the material you’re using is hard enough for the type of application you have in mind.

PCBN is a versatile material that can be used in many industries. In general, it can be used in machining hard materials, such as ferrous metals, and also has a high rate of wear resistance. While it is a tough and durable material, it is not as strong as diamond.

For example, it is useful in machining the covering of an automobile. In addition, this material has a low cost of production. This makes it an attractive option for machining difficult materials. It can even be used in high-speed machining, such as for thermal spraying. It is also a more efficient choice than other materials for cutting hard materials.

Another advantage of PCBN is that it is chemically stable. It does not react with other materials, including iron. Furthermore, it does not oxidize at high temperatures. This property makes PCBN cutting tools more durable and resistant to wear. It is also compatible with a wide range of other materials.

The PCBN Material for Cutting Tools market report provides vital data such as global revenue, CAGR, and growth rate by type. It also covers the competitive landscape and the level of market concentration. Moreover, the report presents the market chain from start to finish. It also highlights manufacturing costs and process analysis, which help to provide detailed information on the market.

Using PCBN for cutting hardened steel is a great option for high-speed machining. In contrast to grinding, PCBN cutting tools can achieve higher machining speeds and are more flexible. They can also handle parts with different shapes. Moreover, they are often used in dry cutting processes, which reduces pollution and saves energy.

PCBN is a hard and flexible material with similar properties to diamond. Its high hardness and compressive strength make it an excellent choice for cutting hardened steel and cast iron. It also has high thermal sensitivity. Its application in milling and other cutting processes is remarkably diverse. Therefore, it is essential to choose the right material for your application.

PCBN cutting tools have excellent edge durability and can last up to 20 times longer than their vitrified counterparts. In addition, they can be used for grinding high-speed materials such as gray cast iron, surface hardening alloy, and high-speed steel. These cutting tools have a higher CBN content, which increases their hardness and wear resistance, and increases thermal conductivity.

When selecting PCBN materials, it is important to select those that are low in ferrite content. Low-ferrite materials will last longer in a PCBN cutting tool, as ferrite will react with the boron element in CBN. Consequently, too much ferrite will increase chemical wear and reduce the tool’s service life.