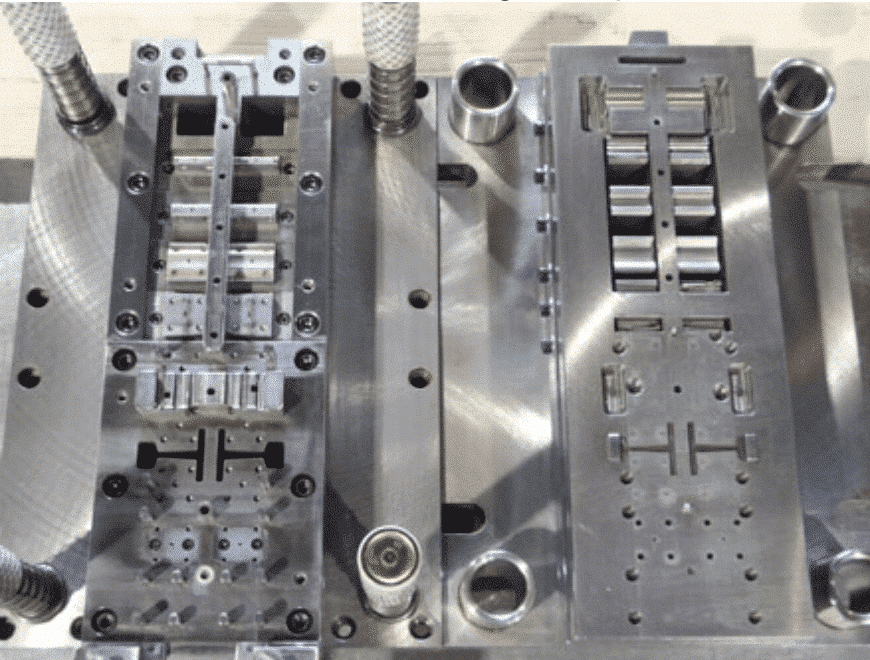

The progressive die is composed of multiple stations. Each station is connected in sequence to complete different processes. A series of different stamping processes are completed in one stroke of the press.

1.Overview

Progressive die (also called continuous die) is composed of multiple stations. Each station is connected in sequence to complete different processes. A series of different stamping processes are performed in one stroke of the press. After one stroke is completed, the material is moved forward by the punch feeder at a fixed step, so that multiple processes can be completed on a pair of dies, such as punching, blanking, bending, trimming, and deep drawing. and many more.

2. Features

(1)Progressive die is a multi-task sequence die, in a pair of molds, can include punching, bending and stretching and other multi-channel processes, with high productivity;

(2)Progressive die operation safety;

(3)Easy to automate;

(4)can use high-speed punch production;

(5)Can reduce the punch, site area, reduce the transport of semi-finished products and warehouse occupancy;

(6)The parts with extremely high dimensions are not suitable for the production of progressive die.

3. Requirments

(1)The part is small;

(2)Large volume;

(3)The material is thin (0.08~2.5mm);

(4) The material is soft;

(5) The shape is more complicated;

(6) The precious metal is not suitable (low utilization rate);

(7) The accuracy is too high (IT10 level below).

4. Differences of different models

Engineering model: Also called “single process model”, it refers to a mold that can only complete one stamping process in one stroke of stamping. After this project is finished, it is necessary to remove the product from the mold manually or with a robot, and then put it into the next mold to continue production until the last process of the mold is finished and the entire product is completed. This kind of mold is simple to repair, but it takes time and labor to produce, requires more labor and time, and has a higher scrap rate.

Compound mold: Common compound mold structure has compound cutting, compound drawing, etc. This kind of mold structure is slightly different from other engineering mold structures. The punch (also known as the male mold or punch) is designed in the lower mold, and the other several mold plates are the lower clamp plate (fixed punch punch), the lower stop plate and the lower stripper plate (outside release). The upper mold sequentially It is composed of a female mold (or knife-edge), an inner release plate and an upper backing plate, and the inner sleeve is hung on the upper backing plate with a contour sleeve, and is then pushed with a lever or a spring. For example, the composite mold used for blanking can be removed within 0.50 mm of the master mold. It must not be lower than the master mold, otherwise the mother mold edge can easily collapse or not be removed. The strength of the inner release should be large enough to lift the product out of the master mold.

Continuous die: also known as “progressive die”, refers to the die that completes two or more punching operations at the same time in the stamping process. This die is difficult to repair and requires experience. A wealth of fitter masters operate, but they are very efficient to produce. If they are fast, they can produce thousands of products in an hour, save labor and time, and have a lower scrap rate.

5. Points of design

The design of the main parts of the mold should pay attention to the following points:

(1) Punch design

The fixing of the punch die adopts the common form of the progressive die. The clearance between the punch and the punch fixing plate is 0.06mm. All the punches are pressed on the punch fixing plate by the punch press plate. The design of the punch press plate protrudes from the bottom of the punch die to increase the strength of the punch die, and the pull-off phenomenon of the punch die is avoided on the basis rate. In order to ensure that the punch has good rigidity, the length of the punch is designed to be 60mm (the length of the individual circular punch is designed to be 52mm).

(2) Die Design

In order to facilitate the manufacture of the concave mold, the concave mold adopts a mosaic structure, and all the concave molds and the concave mold fixed and used 0005mm clearance. Axially fixed are used pressure plate or guide plate with the same set. This not only facilitates the removal of the die, X can prevent lL mold punching when the die insert is brought out of the die fixed pull phenomenon. Because the stamping sheet is softer. The scrap ejected from the mold may have a small rebound, and the main failure mode of the die is plugging. The die edge is designed to be in the form of a 2mm straight wall with a slant of material.

(3) Discharging structure

The design of the discharge structure mainly includes the discharge of round holes, the discharge of punch holes, and the discharge of shaped materials. In order to ensure that the stripper plate plays a role in the precision guiding of the punching punch, the matching gap between the two is 0012 ram; in order to improve the processing degree of the stripper plate and prevent deformation. The stripper plate is divided into two parts; the lower die of the mold is designed with burr edge inserts and embossing mold inserts, the height of which is higher than the upper plane of the die; the stripper plate is designed with a strip groove, so as to ensure that the cross-section is not damaged Mold parts. .